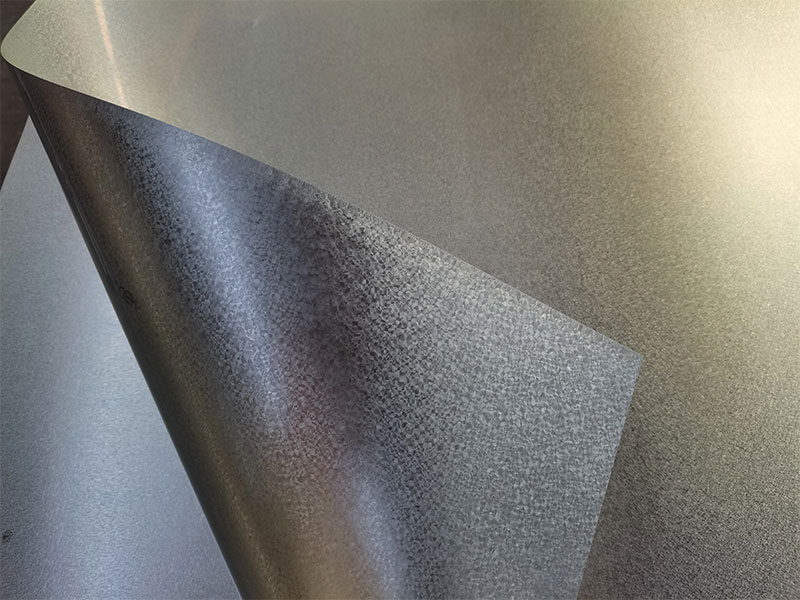

DDS Galvanized Steel is an American Standard A653/A653M deep-drawing grade (Drawing Quality Special, DDS) hot-dip galvanized steel sheet designed for applications requiring high formability and medium strength. DDS galvanized steel combines the good formability and strength of a steel substrate with the corrosion resistance of a plating, and is used in a wide range of medium-complexity deep-drawn parts for automotive, appliance, and architectural applications.

DDS Galvanized Steel for Sale

Wanzhi Group is a hot dipped galvanized steel factory supplier from China, we supply commercial, structural, deep-drawing and ultra-deep-drawing hot dipped galvanized steel according to A653/A653M standard, we can produce coils and plates with thickness from 0.12-6mm, width from 600-1250mm, and we can process profiled plates, strips, tubes, profiles, and so on.

| Standard/Grade | Yield Strength (MPa) | Elongation (%) | Typical Applications |

| A653 CS Type B | 140-280 | ≥22 | Commercial forming |

| A653 DDS | 120-220 | ≥30 | Complex deep drawing |

| A653 EDDS | ≤120 | ≥35 | Ultra-deep drawing |

Properties of DDS Galvanized Steel

DDS galvanized steel suitable for medium strength requirements, ensuring that it is less likely to break during the forming process, and supporting complex deformations (e.g. deep drawing, flanging, expanding) indicates that the material has an excellent ability to deform in the direction of the thickness, reducing the risk of wrinkles.

Mechanical Property

| Property | DDS Type A | DDS Type B | DDS Type C |

| Tensile Strength (MPa) | 270-380 | 260-350 | 240-330 |

| Yield Strength (MPa) | 140-220 | 120-200 | 100-180 |

| Elongation A50 (%) | ≥28 | ≥32 | ≥36 |

| Plastic Strain Ratio r | ≥1.2 | ≥1.5 | ≥1.8 |

| Strain Hardening Index n | ≥0.18 | ≥0.20 | ≥0.22 |

Chemical Composition

- Carbon (C): ≤ 0.02%

- Manganese (Mn): 0.5-1.0%

- Phosphorus (P): ≤ 0.02%

- Sulfur (S): ≤ 0.015%

- Aluminum (Al): 0.01-0.06%

Coating Characteristics

- G30: suitable for dry indoor environments.

- G60: general-purpose, balancing cost and corrosion resistance.

- G90: Highly corrosive environments (e.g. coastal, chemical zones).

- Surface treatment: Chromate passivation (to reduce storage white rust) or chrome-free passivation (environmental requirements) can be added.

Application Scenarios of DDS Galvanized Steel

DDS galvanized steel has excellent corrosion and fatigue resistance, high strength and light weight, and is capable of multi-drawing and complex shaping.

- Automotive industry: doors, hoods, wings, brake brackets, suspension arms, automotive oil pan

- Home appliance manufacturing: washing machine barrels, refrigerator door panels, air conditioning brackets, microwave ovens liner

- Building decoration: indoor ceiling, elevator doors, shopping malls, such as display racks and other decorative panels

- Industrial equipment: control cabinets shells, ventilation ductsDDS

Galvanized Steel Finishes

Wanzhi Group offers a wide range of finishes that can be selected according to the application requirements.

- Painting: Chrome Free Passivation + Epoxy Primer + Top Coat for improved film adhesion, corrosion resistance and aesthetics of the steel.

- Skin Pass: Enhances stamping stability

- Passivation: Chrome-free passivation/phosphating enhances the corrosion resistance of the steel.

DDS Galvanized Steel – FAQ

Question 1: Cracking during deep drawing and forming?

Reason: Draw ratio > 2.0, insufficient lubrication or low material r-value can cause DDS galvanized steel to crack during processing.

Problem 2: White rust (zinc oxide) appears on the plated surface?

Cause: The main cause of white rust on the surface of galvanized steel is humidity, storage environment humidity > 60% or insufficient coating thickness.

Problem 3: Plating peeling off after welding?

Reason: Volatilization or oxidation of zinc layer in the heat affected zone (HAZ) of welding.

Question 4: Paint blistering after painting?

Reason: Always clean the steel surface before galvanizing or painting. Oil or passivation film residues on the plated surface can lead to uneven plating/painting or even premature peeling.

A653/A653M DDS galvanized steel is a balance of high formability and medium strength, allowing you to choose the most cost-effective substrate material + coating based on the complexity of the molding, environmental corrosivity, and cost budget. Wanzhi Group provides OEM ODM service, please feel free to contact us for solution or price.