SGCD1/SGCD2 Galvanized Steel is classified as a deep drawing grade hot dip galvanized steel in the Japanese Industrial Standard (JIS G 3302). Deep drawing grade cold rolled galvanized steel is produced by hot dip galvanizing on the basis of cold rolled steel sheet for deep drawing (SPCD).

SGCD1/SGCD2 Galvanized Steel Characteristics

SGCD1/SGCD2 galvanized steel has a zinc coating with a weight of 40-350g/m² (one side), a thickness of 0.12-6mm (according to JIS G 3302, a deviation of ±0.03mm is permitted for a thickness of ≤0.6mm), and a width of 600-1250mm. 1250mm, special size can be customized.

| Property | SGCD1 | SGCD2 |

| Yield Strength (MPa) | 220-280 | 180-250 |

| Tensile Strength (MPa) | 270-380 | 260-350 |

| Elongation A50 (%) | ≥28 (t≤0.8mm) | ≥34 (t≤0.8mm) |

| Plastic Strain Ratio r | ≥1.4 | ≥1.8 |

| Strain Hardening Index n | ≥0.18 | ≥0.22 |

| Coating Type | Pure Zinc Coating (Zn) | Zinc-Iron Alloy Coating (Zn-Fe) |

| Coating Structure | Single layer of zinc, smooth surface | Double-layer structure |

| Corrosion Resistance | Suitable for dry environments | Suitable for humid/corrosive environments |

| Formability | Suitable for deep drawing, complex forming | Deep drawing performance slightly lower than SGCD1 |

| Surface Roughness | Low (Ra ≤ 0.5μm) | Higher (Ra ≈ 1.0μm) |

| Weldability | Good | Average |

| Cost | Relatively low | Slightly higher |

| Surface Quality | No zinc spangle (or very small zinc spangle) | Allowed slight alloying spots |

SGCD1 vs SGCD2 Recommendations

| Scene | Recommendation |

| Automotive Inner Panels | For non-exposed applications, choose the cost-effective, easy-to-process SGCD1; subsequent coating can compensate for insufficient corrosion resistance |

| Automotive Chassis | For exposure to mud and water, choose SGCD2 with strong corrosion resistance to reduce the risk of chassis rust |

| Household Appliance Casings | For dry environments, choose the smooth-surfaced SGCD1, suitable for direct use or simple coating |

| Outdoor Electrical Cabinets | Choose SGCD2 with excellent salt spray resistance |

| Building Structural Parts | For environments with low corrosion, choose SGCD1 |

| Chemical Equipment | For resistance to acidic environments, choose SGCD2 with a high zinc coating, or stainless steel or nickel-plated steel sheets |

SGCD1/SGCD2 Galvanized Steel Applications

Automotive industry: inner door panels, hood liners, chassis braces (SGCD1 GI steel); bumpers, hubcaps, complex curved coverings (SGCD2 GI steel).

Appliance manufacturing: deep-drawing washing machine drums, microwave oven liners.

Architectural decoration: ceilings, suspended ceiling systems, shaped metal components.

Building and structure: roof and wall panels, ventilation ducts, door and window frames, roller shutters, auxiliary components for steel buildings

Industrial equipment and appliances: control cabinets, distribution box housings, office furniture skeletons, shelves, storage cages, agricultural equipment, HVAC equipment housings

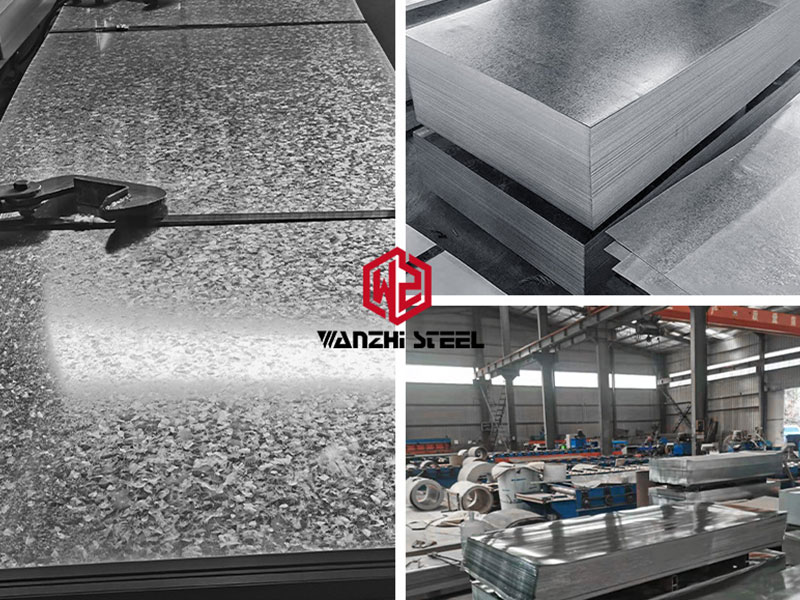

JIS G 3302 Galvanized Steel – Factory

Wanzhi Group galvanized steel factory produces JIS G 3302 SGCC, SGCD1, SGCD2, SGEH and other commercial grade, deep-drawing galvanized steel, Our factory is located in Boxing County, Binzhou City, Shandong Province, China, with two days production line of galvanized steel, with an average production capacity of 20,000 tons per month, we are mainly engaged in the production of raw materials of galvanized steel coils, galvanized steel sheets, galvanized steel strips, etc. Meanwhile, we also offer At the same time, we also provide further processing such as bending, forming, profiling, stamping, surface treatment and so on.

If you are looking for deep-drawing grade galvanized steel, Wanzhi Group can provide SGCD1, SGCD2, SGCD3, DDS, EDDS, DC05+Z, DC06+Z, DX52D+Z and other grades with excellent deep-drawing properties and corrosion resistance.