Galvanized Steel Plate is typically used for heavy loads or in harsh environments, offering high strength and corrosion resistance. Available in flat galvanized coils, it can be formed into various surface structures through cold roll forming, including galvanized corrugated sheet, ribbed sheet, trapezoidal sheet, rectangular sheet, and perforated sheet.

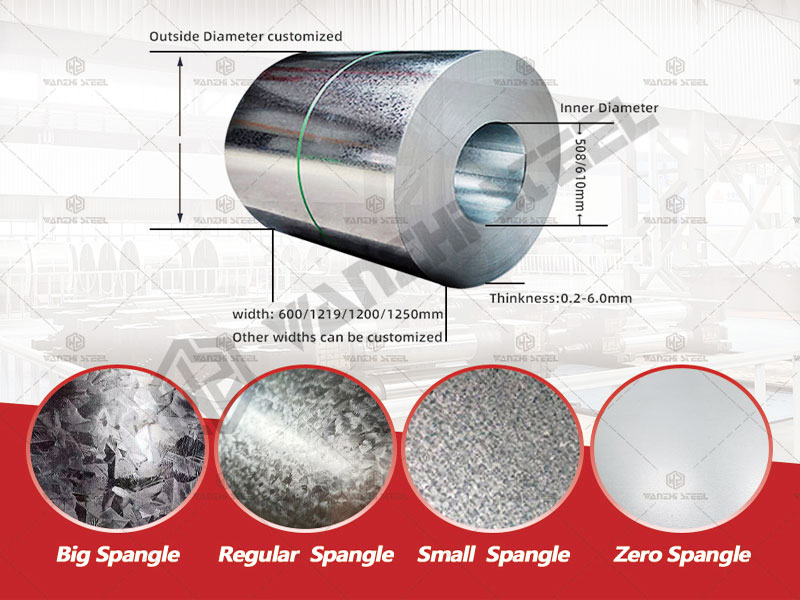

Galvanized Steel Plate – Specifications

Wanzhi Group is a galvanized steel manufacturer from China. We produce and export a wide variety of galvanized steel products. Our galvanized steel plate offers a wide range of specifications to meet diverse application needs. We also offer custom manufacturing services for special specifications.

| Substrate Material | Low Carbon Steel, High Strength Low Alloy Steel, etc. |

| Standard Thickness | 0.15mm – 6.0mm (customizable based on requirements) |

| Common Width | 600-1250mm, 1000mm, 1250mm, 1500mm |

| Standard Length | Standard flat plates (e.g., 2000mm, 2500mm, up to 12 meters or more) |

| Zinc Coating Weight | Z30-350g/m² (Z40, Z60, Z90, Z100, Z120, Z140, Z180, Z275) |

| High Strength Corrosion Resistance | Available with Z350 or higher coating. |

| Standards | Complies with GB/T, ASTM A653, EN 10346, JIS G3302, and other international mainstream standards. |

| Packaging | Standard international packaging (plastic film, moisture-proof paper, galvanized steel sheet, steel bundling, optional wooden pallet) |

| Minimum Order Quantity | 10 tons |

Galvanized Steel Plate – Products

Wanzhi Group offers a variety of surface treatments to meet diverse aesthetic and functional requirements. We can customize various galvanized materials, including spangled galvanized steel plate and zero spangled galvanized steel plate, to meet your application needs.

Spangled

Regular spangled: The galvanized steel plate features a clearly visible zinc crystal pattern, making it a traditional and economical choice. It’s suitable for general structural parts and hardware where aesthetics aren’t a priority.

Small spangled: The zinc crystal pattern is finer and more uniform, resulting in a smoother appearance. It’s an excellent choice for balancing affordability and aesthetics.

No spangled: The no spangled galvanized steel plate has a uniform, dark surface without visible crystal patterns. It’s the preferred substrate for pre-painted steel and is also widely used in applications requiring a uniform and consistent surface.

Surface Treatments

- Chromate passivation: Provides basic white rust protection.

- Chromium-free passivation: An environmentally friendly treatment that complies with the RoHS Directive.

- Oil coating: Enhances short-term rust protection.

- Phosphating: Improves paint film adhesion, making it suitable for subsequent spray coating.

Galvanized Steel Plate – Profiling

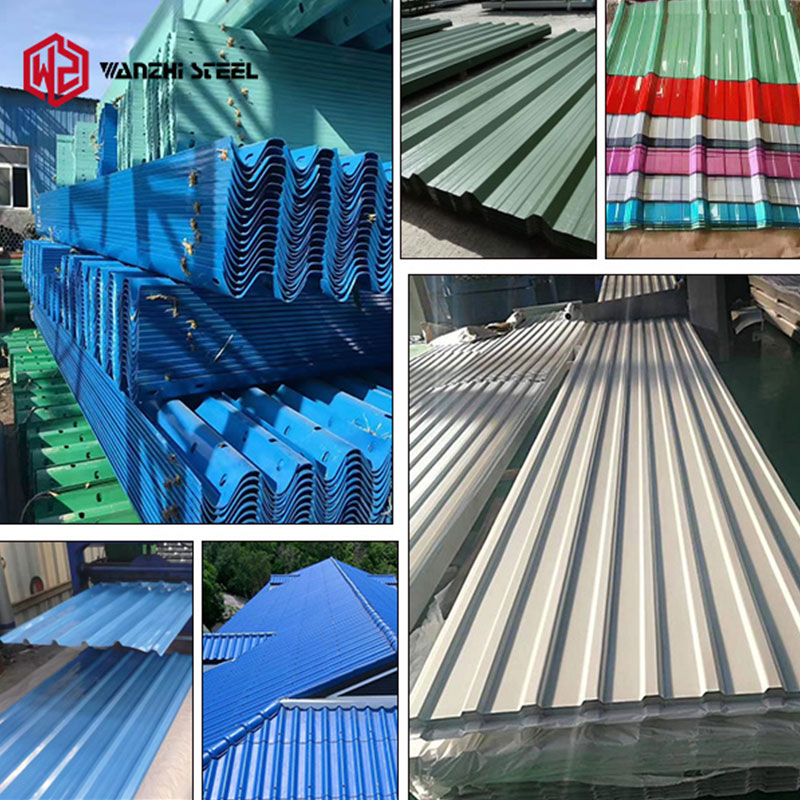

In addition to galvanized flat sheets, galvanized steel’s excellent formability allows for bending and forming. We not only produce galvanized steel plates, but also provide forming services. We can create a variety of structural plate shapes based on your design drawings.

- GI Corrugated Sheet: Classic curved crests offer excellent drainage and are suitable for agricultural buildings and warehouses.

- Trapezoidal/Corrugated Sheet: High rib depth offers strong load-bearing capacity and is suitable for roofs and walls.

- Concealed Cover Sheet: A sleek, modern appearance with concealed fasteners is used for curtain walls in high-end commercial buildings.

- Floor Decking: Available in open and closed decking, these decks are used in steel structure floors, serving as permanent formwork and participating in structural load-bearing.

Galvanized Steel Plate – Stamping

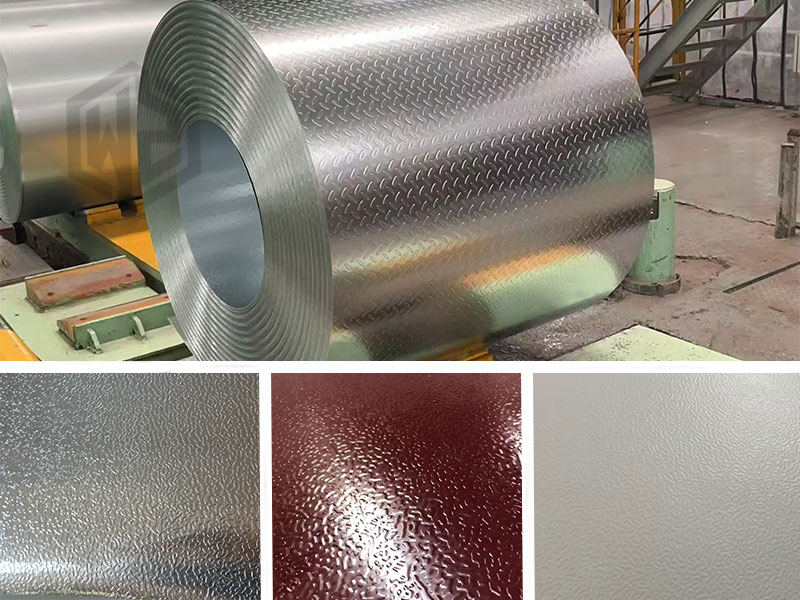

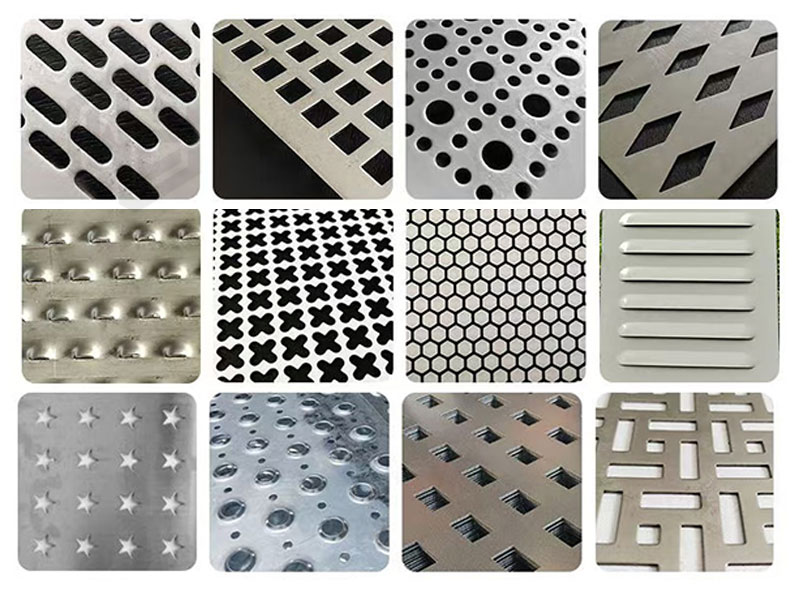

In addition to cold-formed steel sheeting, Wanzhi Group also provides galvanized steel sheet stamping and punching services, enabling us to complete production according to design drawings.

- GI perforated sheet: Galvanized steel sheet with various hole shapes and patterns, including round, square, elongated, hexagonal, and plum blossom holes.

- Embossed Galvanized sheet: Galvanized steel sheet with various surface effects, including wood grain, stone grain, leather grain, diamond, dot, woven, and subtle orange peel textures.

Galvanized Steel Plate – Further Processing

Galvanized steel plate is an ideal base material for further processing, including structural components, galvanized product substrates, and color-coated steel substrates. Processing yields finished products such as galvanized steel pipes, galvanized I-beams, channels, C-beams, Z-beams, U-beams, angles, galvanized roof panels, wall panels, floor decking, lightweight steel keels, guardrails, rolling shutters, galvanized sandwich panels, and color-coated galvanized steel sheet.

- As a structural component substrate, galvanized steel can be directly used for shearing, punching, and welding to manufacture steel frames, shelving, cable trays, ventilation ducts, and other products. Finished products include:

- As a product base material, galvanized steel can be used through stamping, bending, and other processes to manufacture products such as computer cabinets, appliance housings, and office furniture.

- As a color-coated steel substrate, non-spangled galvanized steel (especially galvanized steel) is the optimal substrate for producing high-performance color-coated steel sheets (PPGI), providing long-term corrosion protection.

Galvanized Steel Plate – Customization

We have strong customization capabilities, including inventory for raw materials and standard specifications. We operate seven production lines with an annual production capacity of 600,000 tons. Delivery times are as fast as 5 days and as late as 45 days. Our products include coils, plates, strips, pipes, wire rods, steel structures, and special-shaped plates.

Factory and Production Lines

Wanzhi Group Factory has three modern continuous hot-dip galvanizing lines and two color-coating lines equipped with advanced process control systems. ISO9001 and ISO14001 certified, we ensure consistent product quality and environmentally friendly production.

Customization Range

- Dimensional Customization: We can offer custom thicknesses, widths, and cut-to-length options beyond the standard 0.15-6mm*600-1250mm.

- Zinc Coating Customization: We can customize zinc coatings from Z30 to Z600 or even higher to suit your corrosion environment.

- Surface Customization: You can specify the spangle size, passivation treatment (chrome-free/chrome-containing), phosphating, oiling, and more. Performance Customization: We offer baseplates with varying strength grades (such as DX51D, DX52D, DX54, DS235GD, S355GD) and deep-drawing properties (such as DC51D, DC54D).

Customization Process

- Requirement Confirmation: You provide your application scenario, performance requirements, and technical specifications.

- Solution and Quotation: Our technical team will provide the optimal material solution and a detailed quotation.

- Sample Confirmation (if required): Free samples will be provided for your testing and confirmation.

- Order and Scheduling: Once the contract is signed, the order will be incorporated into our production schedule.

- Production and Quality Control: We conduct rigorous quality inspections during the production process and can provide third-party material certification.

- Delivery and After-Sales: Delivery is completed within 5-45 business days, and we provide comprehensive after-sales service and technical support.

Quality Inspection

- Galvanizing Weight: Checks whether the zinc coating weight meets the requirements.

- Surface Quality: This includes the absence of plating, holes, cracks, dross, excessive plating thickness, scratches, chromic acid stains, and white rust. Mechanical properties: This includes tensile and bending tests. Generally, after bending 180°, the galvanized steel plate must not show any detachment of the zinc layer on the outer surface, and the plate base must be free of cracks and fractures.

- Corrosion resistance testing: This includes salt spray testing, humidity testing, and erosion testing.

Galvanized steel plate is a versatile corrosion-resistant base material that is durable, corrosion-resistant, processable, and economical. Contact us for a free quote!