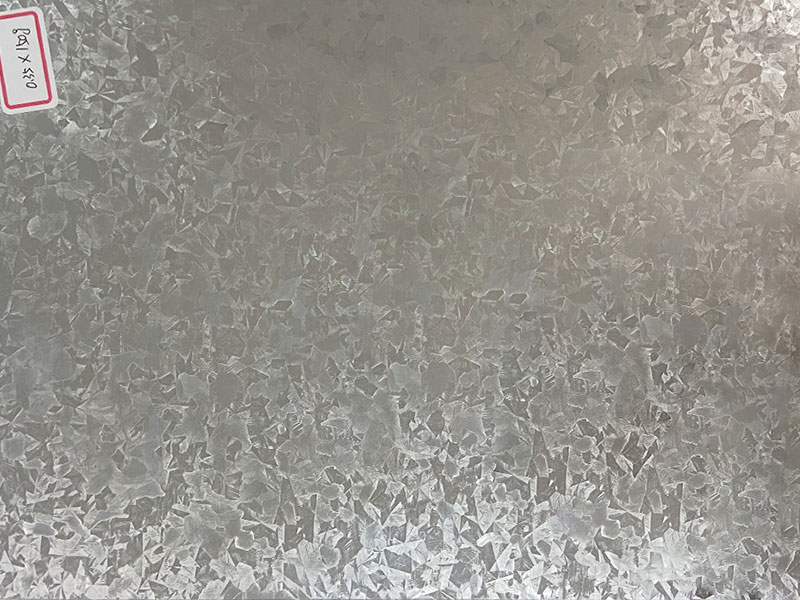

Spangle Galvanized Steel is a hot-dip galvanized steel material characterized by unique “zinc crystal patterns” (spangles) on its surface. These shiny, silvery crystalline patterns—resembling snowflakes or starbursts in various shapes and sizes—are specific metallic crystals formed during the hot-dip processing. Wanzhi Group provides spangle GI steel solutions with large, medium, small, and zero spangles for applications in the construction, home appliance, and transportation sectors.

Formation of Spangles

The spangles on Spangle Galvanized Steel are hexagonal or irregular flake-like crystal structures formed during the hot-dip galvanizing process. They result from the free growth of zinc grains as the molten zinc bath (at approximately 450°C) solidifies on the surface of the cold-rolled substrate. The size of the spangles can be adjusted by controlling the content of “grain promoters” such as lead (Pb), antimony (Sb), or tin (Sn), as well as by regulating the cooling rate.

Types of Spangles

Spangle Galvanized Steel exhibits a metallic luster and comes in various types, including large spangles (≥5 mm) and small spangles (≤2 mm). The spangles are uniformly distributed and free of cracks.

| Zinc Flower Type | Name | Surface Characteristics |

| Large zinc flower | Regular Spangle / Large Spangle | Full crystal flowers, highly decorative, with obvious light reflection |

| Regular zinc flower | Normal Spangle | Balances aesthetics and performance, the most common type |

| Small zinc flower | Minimized Spangle / Small Spangle | Fine crystal grains, good uniformity |

| Zero zinc flower (or No zinc flower) | Spangle-Free / Extra-Smooth | Uniform grayish-white surface, smooth and flat |

Spangle Galvanized Steel for Sale

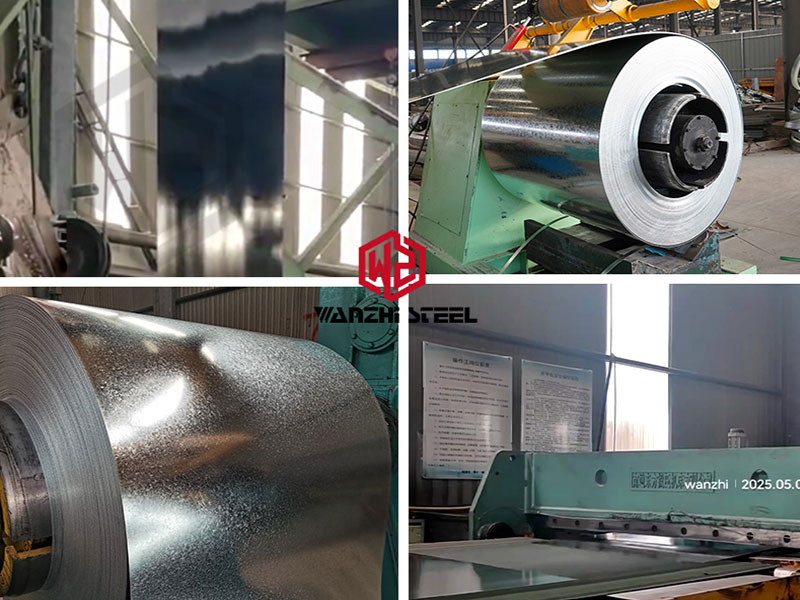

As a leading steel manufacturer and supplier, Wanzhi Group specializes in producing high-quality spangle galvanized steel. Our factory has three coating steel production lines, capable of producing galvanized steel, aluzinc steel, and zinc-aluminum-magnesium steel. Our galvanized steel offers various finishes, including standard spangle and small spangle, and is supplied in coils, sheets, strips, and profiles.

Specifications

| Material | SGCC,S350GD+Z,S550GD+Z,DX51D,DX52D,DX53D, etc |

|---|---|

| Thickness | 0.12mm-6mm |

| Width | The conventional width below 0.5mm is 1000mm, 1200mm, and above is 1000, 1250mm |

| coil weight | 8-10 tons /customized |

| Tolerance | "+/-0.02 mm |

| Substrate Type | Hot rolled coil, Cold rolled coil |

| Surface structure | Zero spangles, Small spangles, Regular spangles, Big spangles |

| Zinc layer thickness | 30g/㎡-275g/㎡ (Z275/G90) |

| Standard | AISI, ASTM, BS, GB, JIS |

| Implementation standards | GB/T2518 GB/T25052, EN10346, JIS G3302, ASTMA653 |

| Certificates | SGS, ISO 9001,CE |

Substrate Material

| Grade | Example of Grade Designation | Yield Strength (MPa) | Applicable Scenarios |

| Commercial Grade | DX51D+Z | ≥140 | Building envelopes, general purposes |

| Structural Grade | S350GD+Z | ≥350 | Load-bearing structures, purlins, shelves |

| High-strength Structural Grade | S550GD+Z | ≥550 |

Coating Grade

| Coating Designation | Double-sided Coating Weight (g/m²) | Recommended Usage Environment |

| Z30 | 30 | Indoor dry environments or for short-term rust prevention |

| Z60 | 60 | Mild outdoor areas, temporary buildings |

| Z80 | 80 | General outdoor areas, low-pollution regions |

| Z100 | 100 | Regular outdoor areas, industrial suburbs, agricultural areas |

| Z120 | 120 | Standard industrial/urban/rural environments |

| Z180 | 180 | High-humidity/industrial zones/coastal and inland areas |

| Z275 | 275 | Harsh industrial/marine/chemical environments |

Wanzhi Factory

- Production Base: Located in Boxing County, Binzhou City, Shandong Province, China (Factory Search: Shandong Wanzhi Steel)

- Production Equipment:2 continuous hot-dip galvanizing lines, 1 aluminum-zinc/zinc-aluminum-magnesium coating line, 3 painting lines, 1 writing board production line, and several forming and processing lines.

- Quality Assurance:Wanzhi Steel Factory is certified with ISO9001, ISO14001, and CE. The factory is equipped with a full set of quality inspection equipment.

- Packaging and Logistics:Plastic film + anti-rust paper + outer galvanized iron sheet packaging + steel strapping + edge protection.

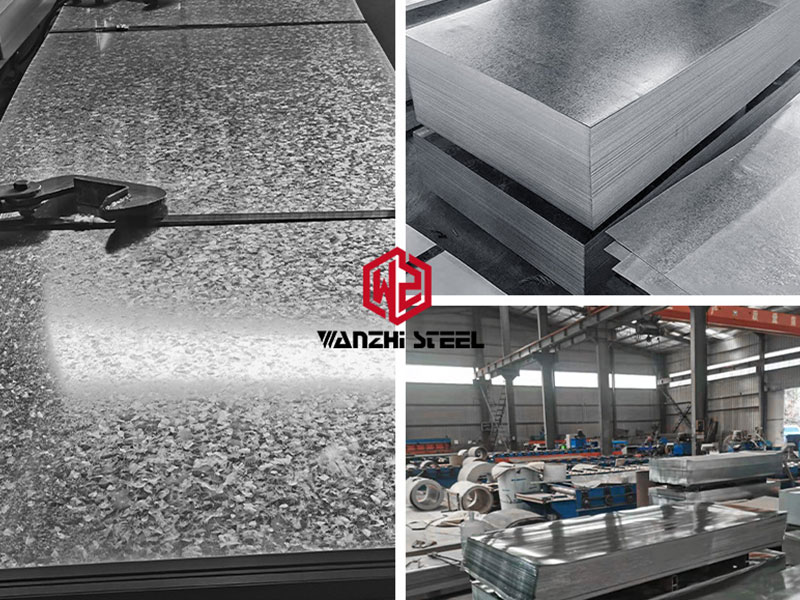

Spangle Galvanized Steel Finished Products

- Spangle Galvanized Steel Raw Materials:Galvanized steel coils, galvanized steel sheets, galvanised steel strips.

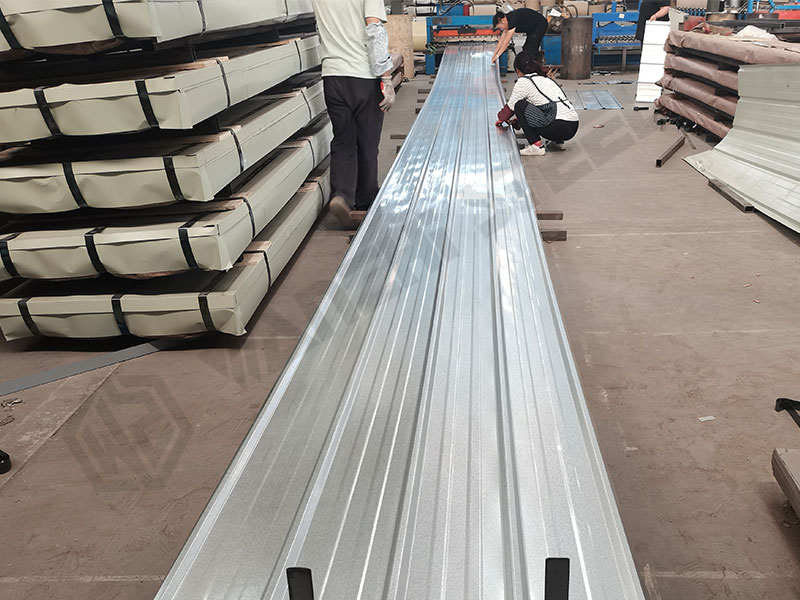

- Spangle Galvanized Profiled Sheets:Corrugated sheets, trapezoidal sheets, standing seam panels, custom cross-sections.

- Galvanized Structural Components:C-purlins/Z-purlins/U-channels, square/round tubes, ceiling keels.

- Building Supporting Products:Gutter and downpipe systems, ventilator bases, architectural decorative trims.

- Custom Finished Products:Various prefabricated components produced according to customer drawings.

Value-Added Processing Services

- Slitting and Cutting:Multiple slitting machines to process galvanized steel strips of various widths.

- Leveling and Shearing:High-precision leveling lines to produce cut-to-size galvanized flat sheets.

- Punching and Stamping:CNC punching machines to produce custom galvanized perforated sheets, ventilation grilles, etc.

- Roll Forming:Multi-specification roll-forming lines to produce galvanized C-purlins, profiled sheets, etc.

- Welding and Assembly:Automatic welding equipment to process galvanized structural parts, frames, etc.

- Surface Treatment:Painting lines, passivation lines to produce pre-passivated, pre-oiled, pre-painted galvanized steel products.

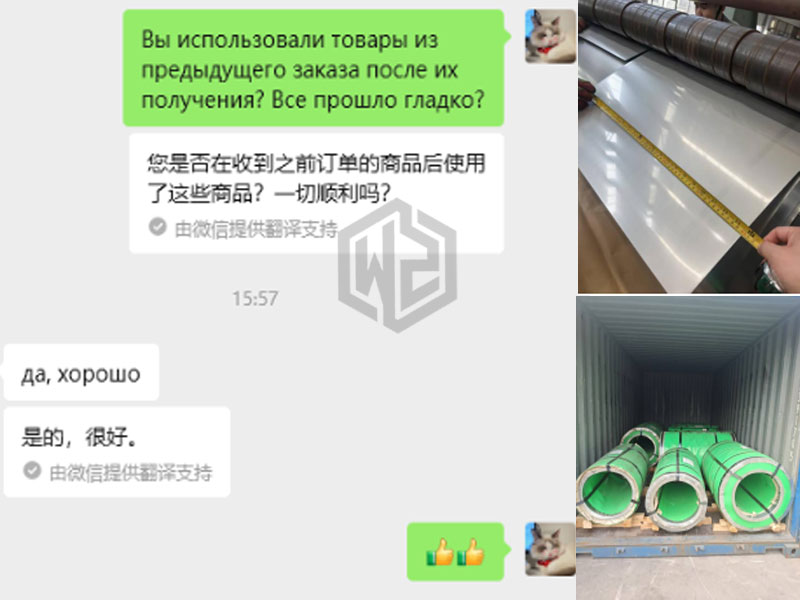

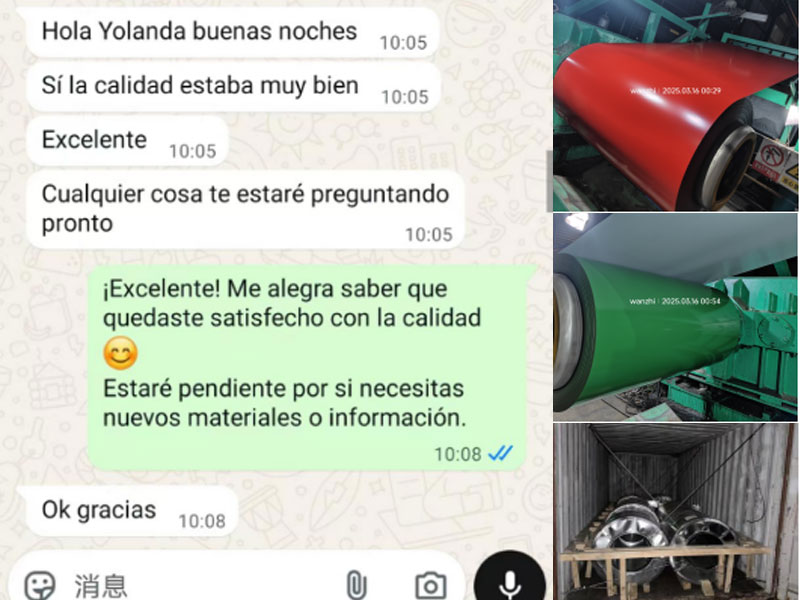

Customer Feedback

To date, our spangle galvanized steel, zero-spangle GI steel, and painted galvanized steel have been exported worldwide. We have also received feedback from end-users across various industries. Let’s take a look at what customers from construction, industrial, agricultural, and other sectors have to say about Wanzhi GI steel!

Application of Spangle Galvanized Steel

The characteristics of different spangle types determine the differentiated application scenarios of Spangle Galvanized. Large-spangle galvanized steel is primarily used in outdoor functional scenarios; small-spangle galvanized steel is mainly applied in indoor mid-to-high-end scenarios; while GI zero-spangle is predominantly used in high-end precision scenarios.

Architecture and Structure

- Indoor steel structures (office buildings, shopping malls)

- Roofs and walls of industrial plants and warehouses

- Exposed components of public buildings

- Roofs/walls of residential and commercial buildings

- Agricultural greenhouses, grain silos, livestock sheds

- Outdoor staircases, walkway gratings, canopies, anti-slip treads

- Retro-style building facades, decorative sunshades

Infrastructure

- Highway guardrails, noise barriers, isolation fences

- Transmission towers, communication towers

- Photovoltaic power station supports (gradually being replaced by zero-spangle galvanized steel)

- Bridge ancillary facilities

- Municipal street light poles

Industry and Agriculture

- Equipment protective covers, ventilation ducts (when appearance requirements are not high)

- Equipment enclosures/cabinets

- Containers, temporary structures

- Greenhouse structural frames

- Livestock farm cages and pens

- Grain storage panels for silos

- Agricultural machinery components

- Ventilation ducts

- Cable trays

- Shelving systems

Spangle-free Hot-dip Galvanized Steel VS Spangle-free Electro-galvanized Steel

| Characteristics | Spangle-Free HDGI | Electro-Galvanized Steel (EGI) |

| Process Essence | Hot-dip metallurgical bonding | Electrolytic physical deposition |

| Coating Structure | Zinc-iron alloy layer + pure zinc layer | Pure zinc layer |

| Coating Thickness | Thick | Thin |

| Corrosion Protection Mechanism | Barrier protection + cathodic sacrificial protection | Mainly barrier protection |

| Surface Characteristics | Uniform grayish-white, slightly rough | Bright and smooth, close to the original plate |

| Neutral Salt Spray Test | 500 – 1500h | 200 – 600h |

| Scratch Protection | Excellent | Average |

| Roughness Ra | 0.8 – 1.5μm | 0.4 – 0.8μm |

| Glossiness | Matte, uniform grayish-white | Bright |

| Processability | Good | Excellent |

| Price Level | Medium | Usually higher |

FAQ – Spangle Galvanized Steel

Does a larger zinc spangle mean better corrosion resistance?

- No. The size of the zinc spangle is determined by the manufacturing process, while corrosion resistance is determined by the weight of the zinc layer.

Can zero-spangle galvanized steel replace stainless steel?

- No. Although zero-spangle galvanized steel looks similar to stainless steel, its corrosion resistance is significantly different.

What precautions should be taken when storing spangle galvanized steel?

- Protect from moisture and scratches.

What are the “white spots” on the surface of large-spangle galvanized steel?

- The white spots on the surface of galvanized steel are “zinc ash” (oxides from the solidification of molten zinc). They can be removed by lightly sanding with sandpaper and do not affect performance.

Can spangle galvanized steel be welded?

- Yes. However, to avoid accelerating corrosion, zinc must be applied to the weld seam.

What is the minimum order quantity?

- Regular products are ordered from one roll. Special specifications or customized products are negotiable.

What is the delivery time?

- 5-45 working days.

Can you provide certificates conforming to specific national standards?

- Wanzhi Group can provide material certificates conforming to standards such as ASTM, EN, JIS, and GB, and can also arrange third-party inspection.

What if I am not satisfied with the zinc spangle effect?

- We recommend requesting a sample for confirmation first. A small sample can be provided for confirmation before mass production. We ensure that the mass-produced product is consistent with the confirmed sample.