Wanzhi Group – China PPGI PPGL manufacturer and supplier, produces a wide range of specifications, colors, patterns and surface effects of prepared steel, providing cost-effective solutions and deep processing services for architectural roofing, walling, home appliance housings, automotive parts and so on.

PPGI PPGL Steel Material Specifications

PPGI (Pre-painted Galvanized Iron) PPGL (Pre-painted Galvalume Steel) are two types of colored metal materials that are roll-applied with a color coating on the surface of metal-coated steel. Popular metal coated steels are galvanized steel and galvalume steel, and coatings include epoxy, polyester, fluorocarbon, silicone-modified polyester, polyvinylidene fluoride, high weathering polyester, and more.

PPGI PPGL Materials

| Parameter | PPGI | PPGL |

|---|---|---|

| Base Material | Hot-dip galvanized steel (GI) or electro-galvanized steel (EG) | Galvanized aluminum steel (surface galvanized or aluminum-zinc alloy layer) |

| Base Thickness | 0.15-6mm | 0.15-6mm |

| Coating Type | Pure zinc (GI) or zinc-iron alloy (GA), coating weight 30~350g/m² (Z60-Z275) | Aluminum-zinc alloy coating (55% aluminum, 43.4% zinc, 1.6% silicon), coating weight 30-350g/m² |

| International Standards | JIS G3302 (SGCC), EN 10346 (DX51D), ASTM A755 | EN 1396 (Aluminum-based color-coated plate), ASTM B209 (Aluminum plate standard) |

PPGI PPGL Specifications

| Grades | GI/GL/SPCC/SPCD/SPCE/DC01-DC07/Q195、Q215、Q235 |

|---|---|

| Colors | Top/Back:RAL,Painted steel,3D Painted steel, etc(can be customized) |

| Thickness | 0.12-1.5 mm |

| Width | 600-1250mm/ customized |

| Coil Weight | 3-6 tons/ customized |

| Substrate Type | Hot dip galvanized, Galvalume, Zinc alloy, Cold rolled steel, Aluminum-zinc plated steel,Zimalium |

| Zinc Coating Thickness | Z30-275g/ ㎡,AZ30-150g/ ㎡ |

| Introduction to Coating | PVDF、HDP、SMP、PE |

| Coating Thickness | Top :10-40 um,Back:5-20 um |

| Inside diameter | 508/610mm |

| Package | Standard export package or as per your requirements |

| Certificates | SGS, ISO 9001,CE |

| Date of Delivery | 5-45 days |

Quality Assurance (QA)

| Certification Type | PPGI | PPGL |

|---|---|---|

| International Standards | – ISO 9001 (Quality Management) – ASTM A755 (Pre-coated steel) – EN 10169 (EU Color-coated steel) |

– ISO 9001 – EN 1396 (Aluminum-based color-coated plate) – ASTM B209 (Aluminum plate) |

| Environmental Certification | RoHS, REACH (Heavy metal restrictions), GB 30981 (Low VOC coatings) | Same as PPGI, additionally required to meet Aluminum Stewardship Initiative (ASI) sustainability standards |

| Industry Certification | – GB/T 12754 (China Color-coated Steel) – JIS G3302 (Japanese Standard) |

– GB/T 23443 (Aluminum-plastic composite board) – AAMA 2605 (US Architectural Aluminum Plate) |

Core Performance

| Performance | PPGI | PPGL |

|---|---|---|

| Salt Spray Test | 500~1000 hours without red rust (ASTM B117) | 1000~2000 hours without corrosion (Aluzinc coating offers better salt spray resistance) |

| Acid and Alkali Resistance | Relatively weak | Excellent |

| Moisture Heat Aging | 1000 hours without bubbling (GB/T 1740) | 1500 hours without bubbling (Aluminum provides better resistance to moisture heat oxidation) |

| Tensile Strength | 270~550MPa (depending on substrate material, e.g., DX51D: 270~350MPa) | 70~150MPa (Aluminum has lower strength, but can be alloyed to reach 200MPa) |

| Elongation | 15%~30% (e.g., DX53D ≥20%) | 20%~40% (Aluminum offers better ductility, suitable for deep drawing) |

| Hardness | Base material hardness: HRB 50~70 Coating hardness: 2H~3H (pencil hardness) |

Base material hardness: HB 30~60 Coating hardness: same as PPGI |

| Thermal Conductivity | Low (50 W/m·K), suitable for thermal insulation scenarios | High (237 W/m·K), suitable for heat dissipation components |

| Electrical Conductivity | High (requires insulation treatment to prevent leakage) | High (but aluminum oxide film can partially insulate) |

| Welding | Requires special galvanized welding materials (to prevent zinc evaporation) | Laser welding or riveting (aluminum base welding requires inert gas protection) |

| Weight | 0.5mm sheet: approx. 3.93kg/m² | 0.5mm sheet: approx. 1.35kg/m² (65% lighter) |

PPGI PPGL Steel Advantages and Applications

PPGI and PPGL is a pre-painted steel with excellent corrosion resistance, heat reflectivity and decorative properties. It is widely used in the construction, automotive, home appliance, energy, industrial equipment, marine and offshore, agriculture, aerospace and electrical and electronic industries, providing durable and aesthetic solutions for a variety of applications.

PPGI Advantages and Applications

PPGI Pre-painted Galvanized Iron is suitable for use in conventional environments.

PPGI Advantages

- Excellent corrosion resistance: Salt spray test ≥ 1000 hours, galvanized and painted layers provide additional protection against oxidation and rust.

- Good surface quality: PPGI steel sheets have a smooth, uniform surface with an aesthetic appearance.

- Long service life: The coating effectively prevents oxidization of the steel sheet and extends the service life of the steel.

- Strong weather resistance: the organic coating rolled on the surface of the steel is resistant to ultraviolet UV irradiation and the erosion of other natural elements.

- Good processing performance: PPGI steel coils and sheets are easy to process and can be cut, bent and other processing operations to adapt to a variety of needs.

- High strength: Tensile strength of 270~550MPa, can bear weight and resist pressure.

PPGI Applications

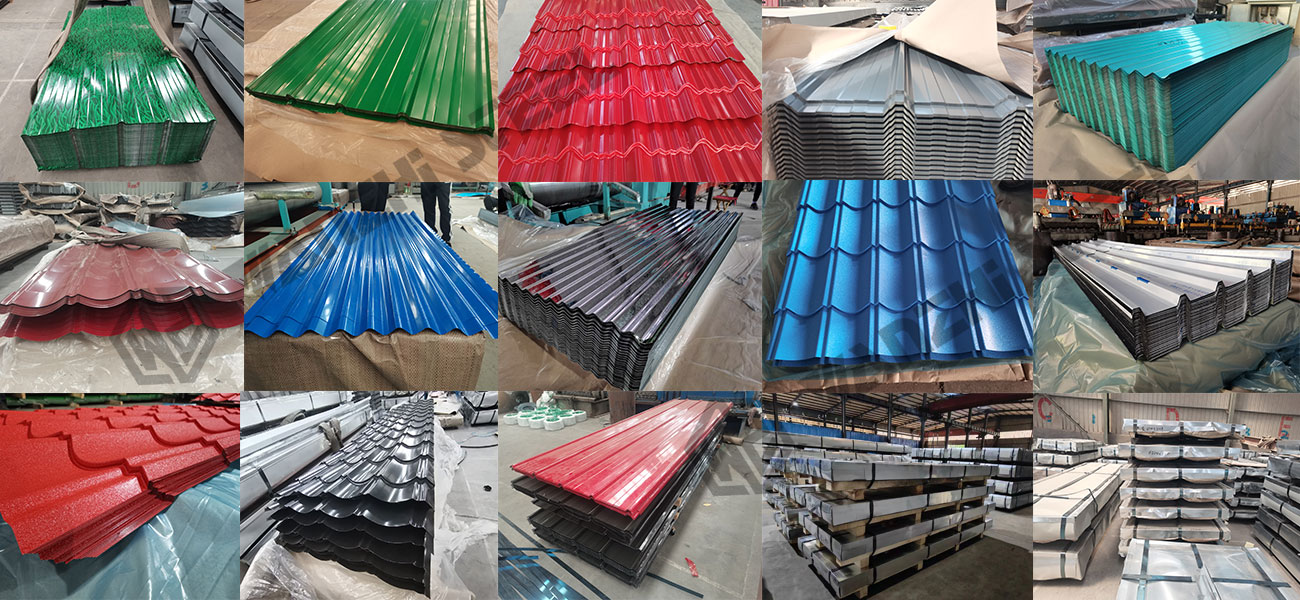

- Construction industry: roof/wall color steel sheet, fences, doors and windows, noise barriers, industrial plants and other construction materials.

- Home appliance industry: refrigerator, air conditioner, washing machine and other home appliances shell, oven lining.

- Automobile industry: automobile parts, compartment panels, truck cargo boxes, chassis guards.

- Commercial facilities: wall decoration and sunshade for stores and offices.

- Industrial equipment: ventilation ducts, storage shelves, agricultural machinery shell.

PPGL Advantages and Applications

PPGL (Pre-painted Galvalume Steel) performs better in more demanding environments.

PPGL Advantage

- Higher corrosion resistance: Aluminum-zinc alloy plating (55% Al) + coating, salt spray resistance ≥ 2000 hours, PPGL has better corrosion resistance than PPGI, especially for coastal and humid areas.

- Higher heat reflectivity: Aluminized zinc coating has higher heat reflectivity.

- High temperature resistance: PPGL is particularly suitable for use in high temperature environments due to the ability of the aluminized zinc coating and functional coatings to withstand higher temperatures.

- Superior processability: PPGL has high compressive and tensile resistance, allowing for more complex processing and molding to suit a wide range of industrial needs.

- Thermal/Electrical Conductivity: High thermal conductivity (237 W/m-K).

- Aesthetics: PPGL coatings have flat surfaces, rich colors, and diverse surface effects for more decorative applications.

PPGL Applications

- Construction industry: Mainly used for roofing materials, wall and facade decoration, curtain wall/ceiling (imitation stone/metal texture), luxury goods display cases.

- Home appliance industry: air-conditioner housings, refrigerator exteriors, etc.

- Agriculture and greenhouses: construction of greenhouses and agricultural facilities.

- Automobile industry: automobile exterior decoration and chassis part, new energy vehicle battery heat sink.

- Shipbuilding and marine engineering: yacht decks, marina facilities, desalination equipment.

- Electronics and heat dissipation: 5G base station shell, server chassis

- Aerospace: aircraft interior panels, luggage compartments, satellite cooling components

PPGI PPGL Steel Price

Wanzhi Group produces many kinds of PPGI PPGL, from substrate material specification, to color, surface effect and so on, we can design and produce according to different application requirements, so our steel price range is very wide, the price of color coated steel is in the range of 600-1000USD per ton, and you can get a higher discount if you buy in bulk, Wanzhi Group is coated steel OEM and ODM, tell us your need or application scenario to get the most competitive price and most cost-effective solution.

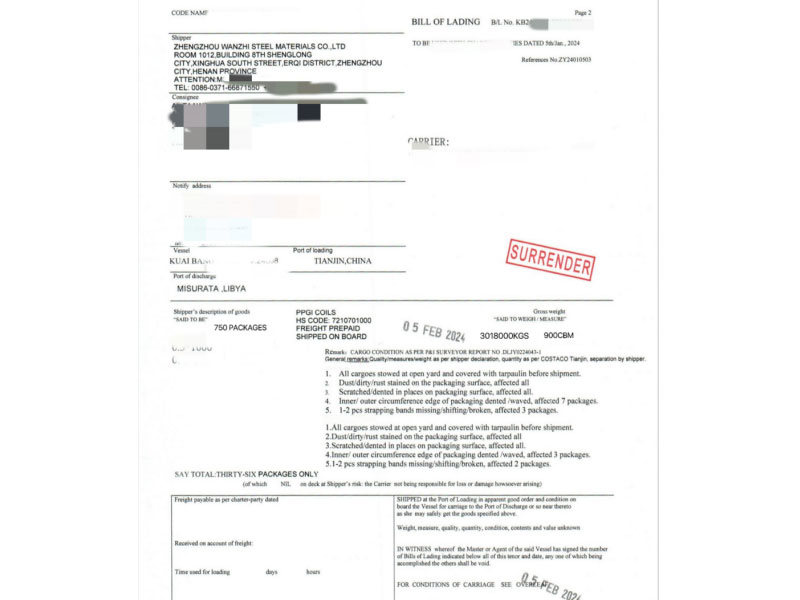

PPGI PPGL Steel Suppliers

Our factory is located in Boxing County, Binzhou City, Shandong Province, China, with 3 PPGI PPGL production lines and one writing board production line, our factory is ISO 9001, ISO14001 certified, and our products Billets, HRC, CRC, GI, GL, PPGI, Rebar, Tube, Wire rod, etc, meet the following requirements GB, EN, JIS, ASTM and other international standards. We have exported steel products to more than 100 countries and regions around the world since 2011, and have rich experience in production and export.

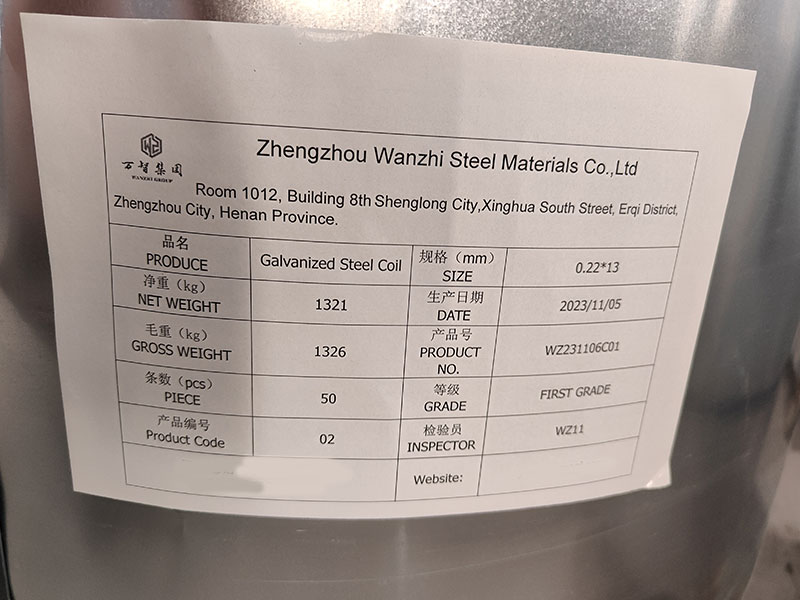

Customer Testimonials and Cases

Our customers include retailers, wholesalers, traders, factories, construction sites, etc. all over the world. We provide on-demand and design & build services for different applications and have received positive feedback from many of our regular customers on the quality, quantity and delivery of our products.

Delivery Time

We have 7 production lines, 4 of which are for color coated products and the rest are for metal coated products. The annual production capacity is 600,000 tons, because we have cold rolled steel coils, hot rolled steel coils, regular type metal coated steel coils/alloy coated steel coils in stock, so our delivery time is 5 days at the earliest and 45 days at the latest. If you need samples or product quality certificates, don’t hesitate to contact us!

Pre-painted Steel PPGI PPGL Customized Services

In addition to manufacturing to specified specifications, one of our greatest strengths as a PPGI PPGL factory supplier is our ability to provide design-to-production services to meet the needs of a wide variety of applications.

Material Customization

- Substrate material selection: According to the customer’s needs, different substrates can be selected, such as ordinary steel plate, low alloy steel or stainless steel, etc., to provide different strength, corrosion resistance and other properties according to the different environments.

- Coating thickness customization: According to the actual needs, the thickness of galvanized or aluzinc steel can be customized, so as to enhance the corrosion resistance and service life of the steel plate.

- Coating type: Customers can choose different kinds of coatings, such as polyester, fluorocarbon, acrylic, etc., according to their needs, and different coatings provide different properties such as weather resistance and color stability.

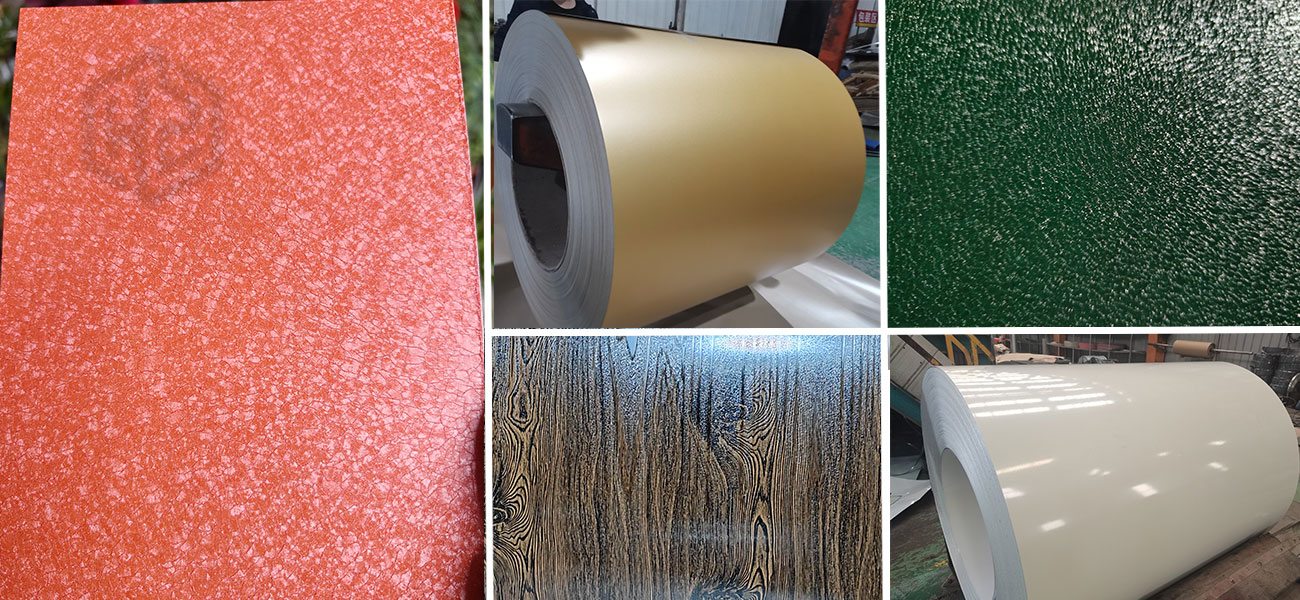

Appearance Customization

- Color customization: The coatings of PPGI and PPGL steel sheets can be customized in colors according to customers’ design requirements. Common colors include blue, white, red, green, etc. They can also be selected according to RAL color cards or samples.

- Surface finishes: Surface finishes can be customized, such as smooth, textured, stone-like, metallic or frosted effects, as well as special appearance requirements.

- Surface protection: additional anti-fingerprint coatings, UV-resistant coatings, etc. can be provided on request to increase the durability and aesthetics of the steel sheet surface.

Finished Product Customization

- Size customization: Different widths, lengths and thicknesses can be customized, and cutting to specified dimensions ensures that the material meets project needs and processing requirements.

- Shape customization: Steel sheets can be customized in shapes such as curled forms, flat forms, corrugated forms, imitating traditional tile forms or forms with special edges.

- Processing services: A range of post-processing services are available, including punching, cutting, bending, forming, slitting, etc.

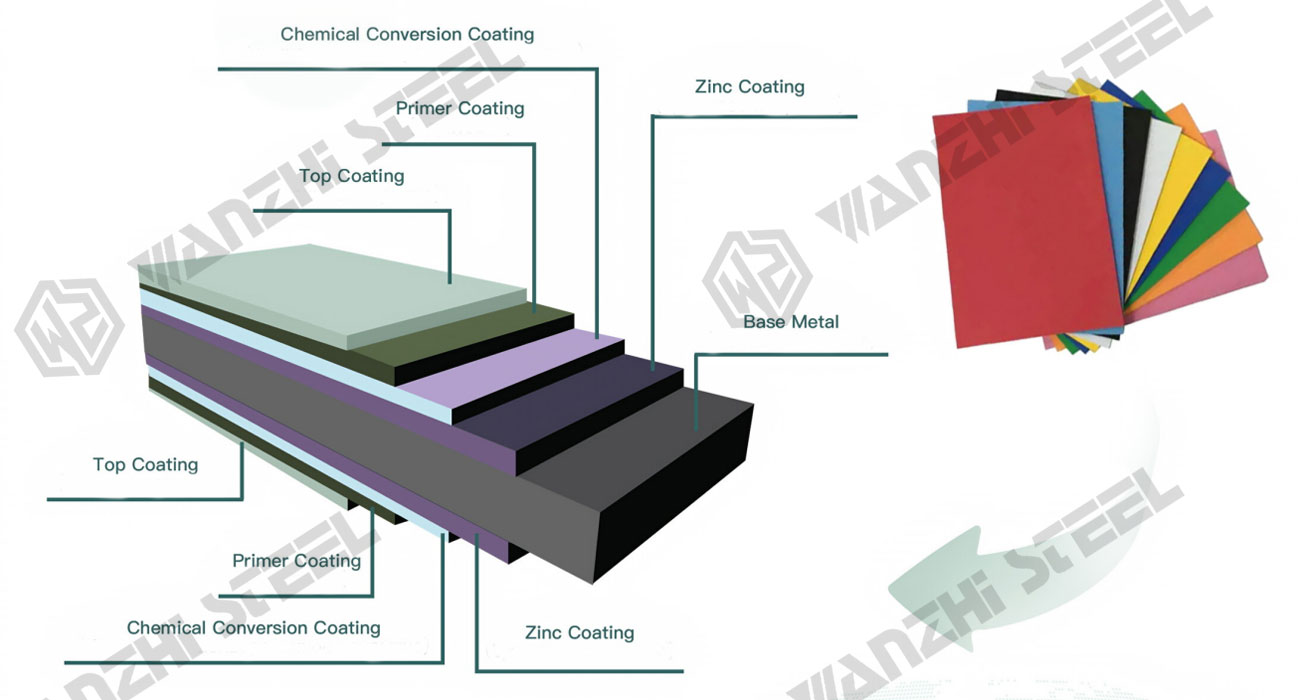

PPGI PPGL Process

Steel substrate (cold rolled sheet) → degreasing and cleaning → hot-dip galvanizing (GI) or electro-galvanizing (EG) / galvanizing (GL) → surface passivation (chroming / chrome-free treatment) → primer coating → topcoating → high temperature curing → cooling → coiling / slitting

Structures

- Substrate

- Chemical conversion film

- Primer

- Topcoat

Production Process

- Degreasing: Removal of grease and oxides from the steel surface using lye, pitting, etc.

- Hot Dip Galvanizing: The cleaned steel is immersed in a solution (zinc/aluminum-zinc solution) at 450~465°C to form a uniform metal/alloy coating.

- Passivation: Chromate treatment/chrome free treatment to form a passivated film on the surface of GI GL steel.

- Coating: GI GL steel is coated with one or more layers of organic coatings by roller coating in a choice of colors and paints.

- Curing and Cooling: The coated PPGI PPGL is heated to cure the coating and the substrate. Cooling: The coated PPGI PPGL is heated and cured to make the coating and the substrate tightly bonded.

- Quality inspection and cutting: After production, the color coated steel needs to be inspected for surface effect, color difference, coating adhesion, salt spray resistance, etc. Qualified products will be slit, cut and packaged according to requirements.

Core Inspection Items

| Test Item | PPGI Test Standard | PPGL Test Standard |

|---|---|---|

| Coating Adhesion | ASTM D3359 (Scratch method, ≥4B) | ASTM D3359 (same as PPGI) |

| Salt Spray Test | ASTM B117 (≥500 hours without red rust) | ASTM B117 (≥1000 hours without corrosion, aluminum-based salt spray resistance is better) |

| Weathering Test | ASTM G154 (QUV UV aging ≥2000 hours, ΔE ≤ 2.0) | Same as PPGI, but aluminum substrate UV degradation resistance is better) |

| Bending Performance | ISO 7438 (180° bending without cracking, 0T ~ 2T radius) | ISO 7438 (aluminum-based ductility is better, can be 0T bending) |

PPGI PPGL Material Recommendation

| Scenario | Requirements | Recommended Material | Reason |

|---|---|---|---|

| Building Roof | Limited budget + High strength | PPGI | Low cost, strength meets wind pressure resistance requirements, suitable for load-bearing structures. |

| Ship Deck | Lightweight + Salt fog resistance | PPGL | Aluminum-based, resistant to seawater corrosion, triple protection (aluminum-zinc coating + coating), lightweight reduces ship load. |

| High-End Curtain Wall | Quick processing + Aesthetic | PPGL | High surface texture, low cost to achieve decorative effect, lifespan over 30 years, maintenance-free. |

| Home Appliance Shell | Mass production / Heat dissipation / Conductivity | PPGI | High ductility suitable for stamping, cost control. |

| Coastal/Industrial | Extreme environment lifespan | PPGL | Maintenance-free throughout the entire lifecycle. |

Wanzhi Group PPGI PPGL materials can be tailored to meet specific needs to ensure that they meet different functional and aesthetic requirements in the construction, home appliance, automotive and other industries, if you are choosing a colored metal material for your project, please feel free to contact us for a price list.