Stainless steel factory supplier – Wanzhi Group, sells austenitic/ferritic/martensitic/duplex/precipitation hardening alloy steel in various material types and specifications, shapes. Customized coils, plates, tubes, profiles, embossed sheets, foils and other finished products are available, as well as slitting, bending, forming and other additional services.

Stainless Steel Definition

Stainless steel is an alloy steel with iron (Fe) as its matrix and chromium (Cr) ≥ 10.5% added. It can resist acid, alkali, salt and atmospheric erosion through the formation of a dense chromium oxide (Cr₂O₃) protective film by chromium to achieve corrosion resistance and a lifespan up to 5-10 times that of ordinary carbon steel.

Material Characteristics

- Corrosion resistance: can resist the chemical and marine environment of acid, alkali, salt erosion.

- High strength: martensitic stainless steel hardness HRC ≥ 55, duplex stainless steel tensile strength ≥ 620MPa, 2 times that of ordinary carbon steel.

- High temperature resistance: high temperature oxidation resistance, 310S stainless steel temperature resistance up to 1150 ° C.

- Hygiene: Ra ≤ 0.8μm, non-porous surface inhibit bacterial growth, in line with medical and food standards.

- Aesthetics: Stainless steel surface can be polished, brushed, printed, coated, decorative.

- Recyclability: 100% recyclable.

Industry Standards

- ISO Standards: ISO 683-1, ISO 4954, ISO 10270, ISO 15510

- EN Standard: EN 10088-1, EN 10088-2, EN 10088-3

- ASTM Standard: ASTM A240, ASTM A276, ASTM A312

- JIS standard: JIS G4305, JIS G4303

- GB Standard: GB/T 20878, GB/T 3280

Stainless Steel Types

According to the crystal structure and magnetic classification, stainless steel can be divided into five categories, of which the popular models are 304, 316 (austenitic ), 403, 409, 446 (ferritic), 410, 450, 440C (martensitic), 2205, 2507 (duplex ), 17-4PH, 15-5PH (precipitation hardening), and so on.

| Grade | Composition | Tensile Strength | Corrosion Resistance |

|---|---|---|---|

| 304 | Cr 18-20%, Ni 8-10.5% | Tensile Strength ≥ 515 MPa | Resistant to atmospheric and freshwater corrosion |

| 316 | Cr 16-18%, Ni 10-14%, Mo 2-3% | Tensile Strength ≥ 515 MPa | Resistant to acids, alkalis, and seawater |

| 321 | Ti (Titanium) stabilized | Excellent high-temperature strength | Resistant to intergranular corrosion |

| 430 | Cr 16-18%, Low carbon (C ≤ 0.12%) | Tensile Strength ≥ 450 MPa | Resistant to nitric acid and weak acids |

| 446 | Cr 23-27%, High chromium, low nickel | Oxidation resistance up to 1100°C | Resistant to high-temperature oxidation |

| 410 | Cr 11.5-13.5%, Low carbon | Hardness HRC 35-45 | General corrosion resistance |

| 440C | Cr 16-18%, C 0.95-1.2% | Hardness HRC 58-60 | Wear-resistant, weak corrosion resistance |

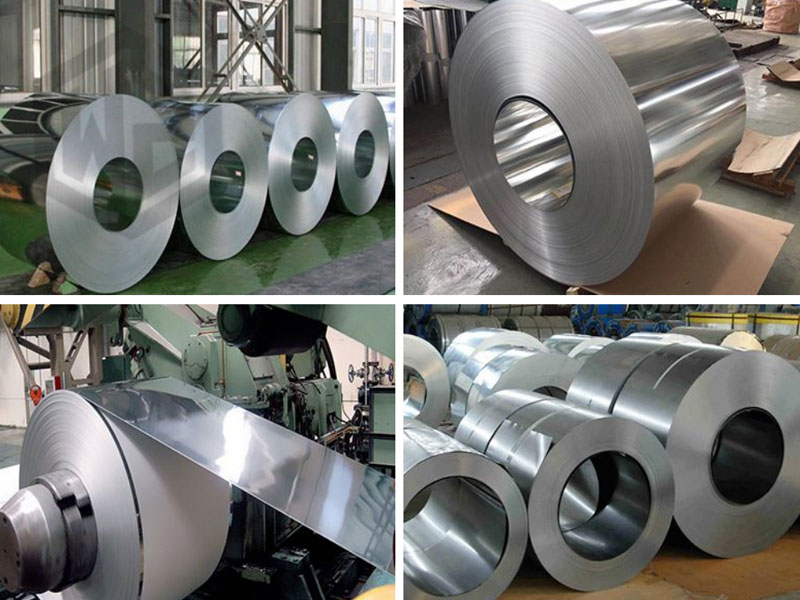

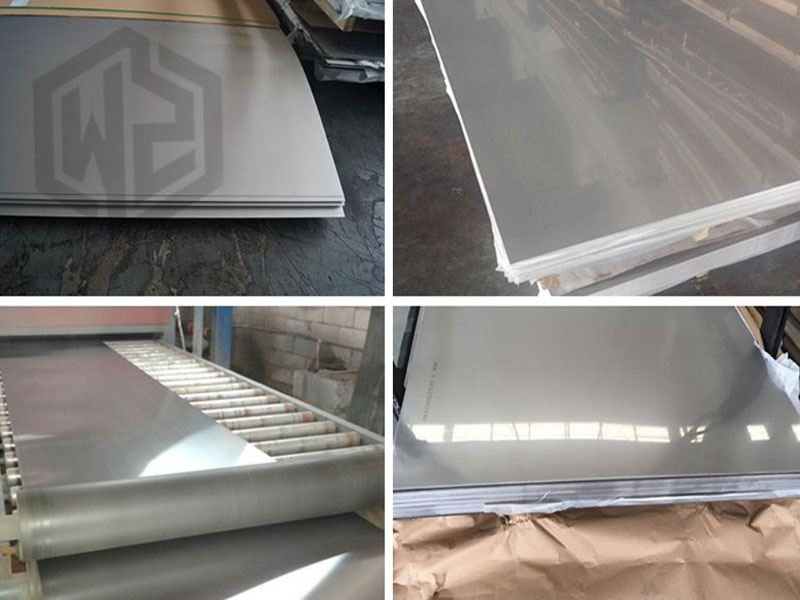

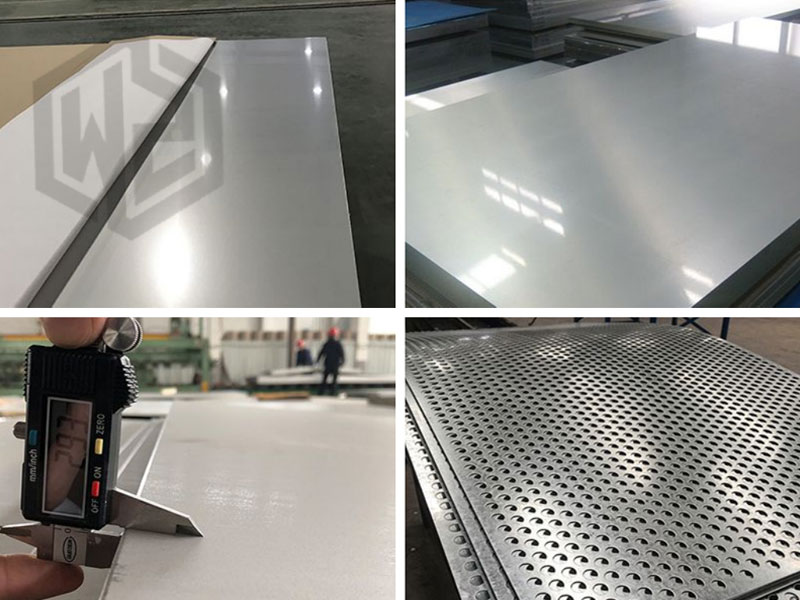

Stainless Steel Products

Wanzhi Group supplies stainless steel sheet, tubes, bars, wires and other industrial materials in accordance with international standards such as ISO, EN, ASTM, GB, JIS , and so on.

Specifications

| Item | Product Parameters |

|---|---|

| Product Name | Stainless steel coil, stainless steel plate |

| Thickness | 0.1-300mm or as per customer requirements |

| Length/Width | As per customer requirements |

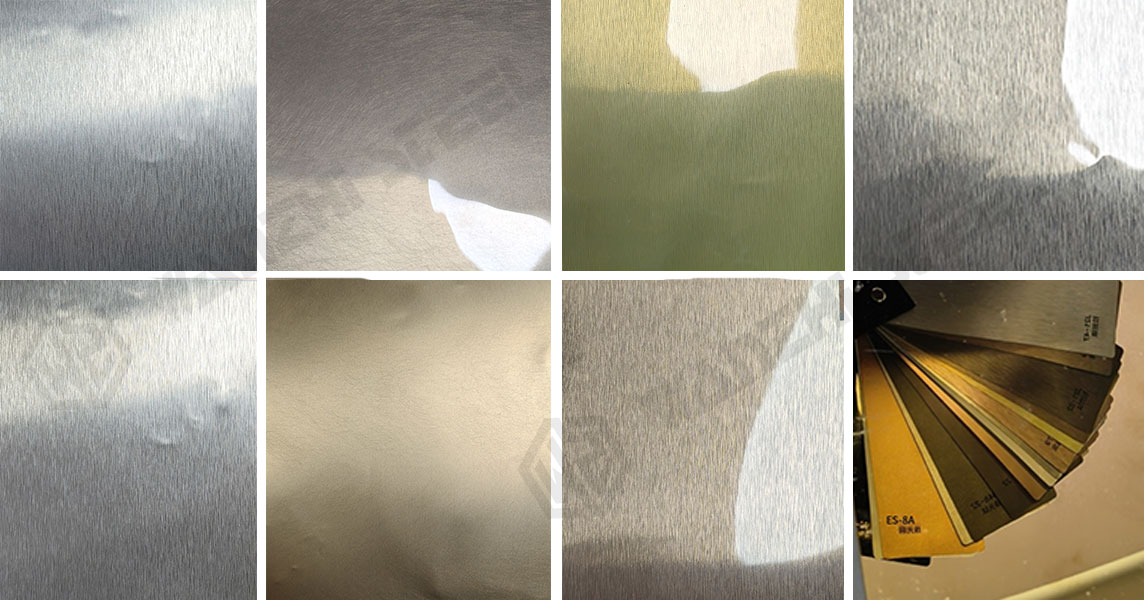

| Surface Treatment | 2B, BA, HL, No.1, No.4, Mirror, Pickled, Satin, Antique, Coated, PVD Coating, etc. |

| Standards | AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN |

| Material Grades | 201, 202, 301, 302, 303, 304, 304L, 304H, 316, 430, 410, etc. |

| Process | Cold Rolled, Hot Rolled |

| Applications | Food, Natural Gas, Metallurgy, Biotechnology, Electronics, Chemical, Petroleum, Boilers, Nuclear Energy, Medical, Equipment, Fertilizers, etc. |

Special Specifications

- High nitrogen stainless steel (e.g. Nitronic 50)

- Antibacterial stainless steels (with Cu/Ag ions)

- High temperature resistant stainless steel (e.g. 310S)

Shape

- U-channel

- Honeycomb plate

- Spiral tube

- Microporous arrays

- Curved molding

- Openwork engraving

Functional surface

- Electrolytic polishing: Roughness Ra≤0.1μm, corrosion resistance +30%.

- PVD coating: hardness HV ≥ 2000, wear resistance increased by 5 times.

- Fluorocarbon spraying: UV aging life ≥ 20 years

- Nano-coating: hydrophobicity angle ≥150°, anti-fingerprint, easy to clean

Decorative Surface

- Mirror polishing: reflectivity ≥ 90%, as clear as a mirror.

- Color oxidation: Gradient (blue/gold/purple)

- Etched texture: customized pattern (wood grain/geometric pattern)

- Sandblasted matte: uniformly frosted texture, delicate touch

Stainless Steel Advantages and Applications

Stainless steel has the advantages of high corrosion resistance, high temperature resistance, high strength, good abrasion resistance, good dirt resistance, easy to clean, good processing properties, etc. It is an indispensable material for construction and decoration, food industry, medical devices, chemical industry, automotive and aviation, energy industry and consumer goods production.

- Architectural curtain wall keels, conveyor belt rails

- Lightweight aerospace structures

- Chemical reactor heat exchanger tubes

- Filter plates, silencers

- Kitchenware, building materials, medical equipment

- Chemical equipment, ship components

- Aero-engine components, high-temperature piping

- Appliance housings, decorative materials, architectural surface decoration

- Heat treatment furnace parts, burners

- Turbine blades, bolts

- Scalpels, bearings, valves

- Art installations, high-end signs, cell phone frames

Buy Stainless Steel

Wanzhi Group is a stainless steel supplier with more than 10 years of export experience. Our products meet the international standards such as ISO, ASTM, etc., and the materials are certified by SGS and CE. We supply steel in regular materials and specifications and offer customized service for specific size or type, please contact us for product brochures and price lists.

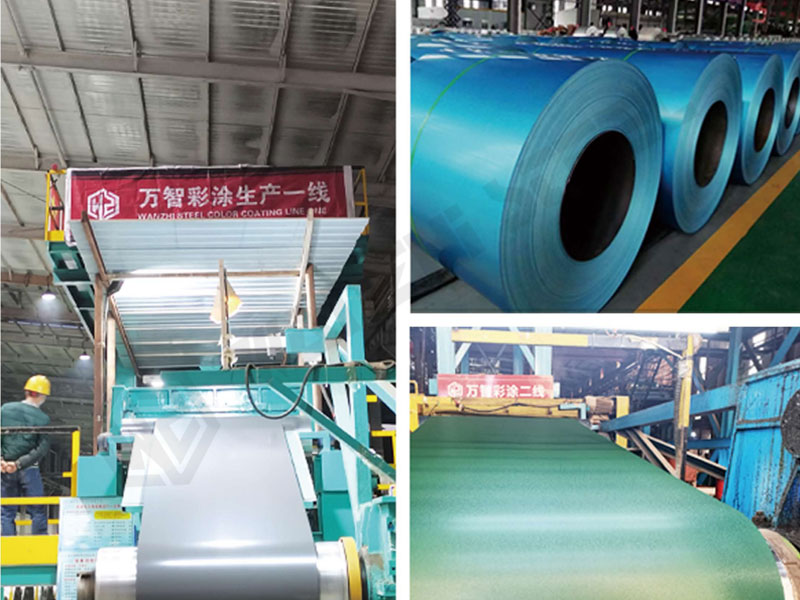

Supplier

As a professional steel supplier, Wanzhi Steel has supplied carbon steel, coated steel, alloy steel, and other metal materials to customers in more than 100 countries and regions around the world. Our coated steel production line is located in Boxing County, Binzhou City, Shandong Province, China. Please feel free to contact us for samples or factory visit.

Service

We provide one-stop service: from raw material sourcing, solution customization, design, production, quality control, transportation, to after-sales service to provide customers with comprehensive services from different aspects, to effectively ensure product quality and save purchasing time and cost.

Stainless Steel Procurement Guide

- Food processing industry preferred non-toxic, easy to clean, organic acid corrosion-resistant material grade, recommended 304, 316L and so on.

- Marine engineering against high resistance to chlorine ion corrosion requirements, recommended 316, 2205 duplex steel

- High-temperature environments choose high oxidation temperature 310S (austenitic), 446 (ferritic).

- For medical equipment, 316L and 420 are recommended for their high biocompatibility to inhibit the growth of bacteria.

Stainless Steel Production

Preparation of raw materials

- Iron ore, chromium ore, nickel ore, scrap steel.

- Adjust the proportion of chromium, nickel, molybdenum (Mo), carbon (C) and other alloys according to the required ss material types.

Steelmaking process

- First of all, high temperature melting scrap steel and iron alloy and other materials.

- Passed into the argon and oxygen gas mixture, precise control of carbon content.

- Finally, continuous casting (slab or ingot).

Hot and cold rolling

- Slabs are heated to 1200°C and rolled into thick plates (3-20mm).

- Further thinning to 0.3-3mm at room temperature.

Annealing and pickling

- Heated to 1000℃ and then slowly cooled to eliminate work hardening and restore the ductility of the material.

- Nitric acid + hydrofluoric acid solution to remove the surface oxidized layer, revealing the metal luster.

Surface treatment and finishing

- Mechanical/electrolytic polishing to realize mirror surface, brushed and other effects.

- PVD coating to enhance wear resistance or color diversity.

FAQ

What is the difference between 304 and 304L?

304L is a low carbon version of ss material 304 with better corrosion resistance, especially in welded areas where carbides are less likely to form because of the lower carbon content.

What should I do if my ss material is rusty?

It can be cleaned with stainless steel cleaners or special rust removers, or repaired using special polishing methods for ss material.

ss Material surface scratches, deformation and other problems how to deal with?

Fine sandpaper can be used to gently sand, or use stainless steel repair paste to deal with, serious deformation may need to be re-processed.

How to remove stains, scale or rust on ss material surface?

Use vinegar, lemon juice, special cleaner or soft cloth to wipe.

How to quickly identify the ss material?

It can be identified by magnetic test (304 stainless steel does not attract magnetism, 430 stainless steel attracts magnetism) or chemical reagent test.

Why is duplex ss material stronger?

Because duplex stainless steel combines the characteristics of austenite and ferrite to enhance corrosion resistance and strength.

Can ss Material Rust?

Although stainless steel is resistant to corrosion, it may rust under extreme conditions such as prolonged exposure to chlorine.

Wanzhi Group supplies stainless steel materials for medical, food, construction, energy, industrial production and other projects, either to specified dimensions or designed to meet the needs of the application. If you need a specialized supplier, then contact us!