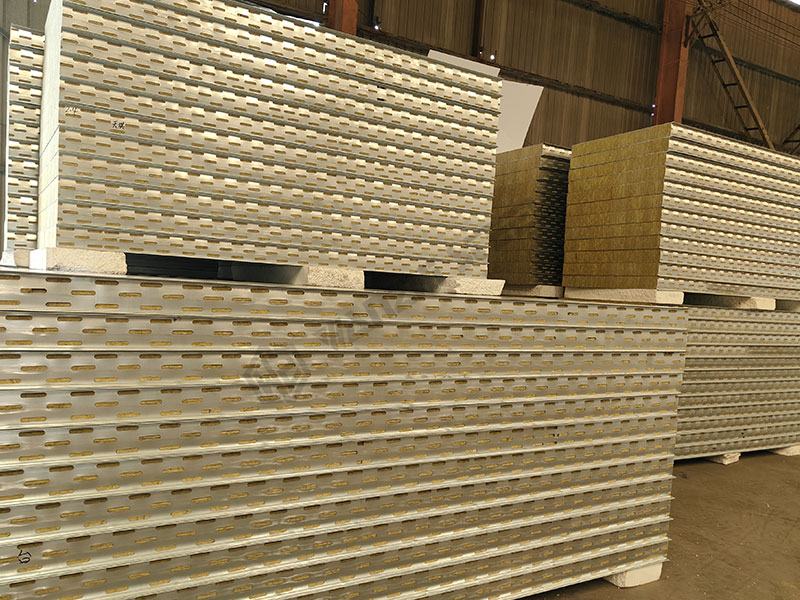

Sandwich panels are a kind of composite panels with thermal and acoustic insulation and fire prevention and corrosion prevention and other efficacies, in which the bending strength of metal sandwich panels can reach 100~300 MPa, realizing the perfect combination of lightweight, high strength and multi-functionality.

What is Sandwich Panel?

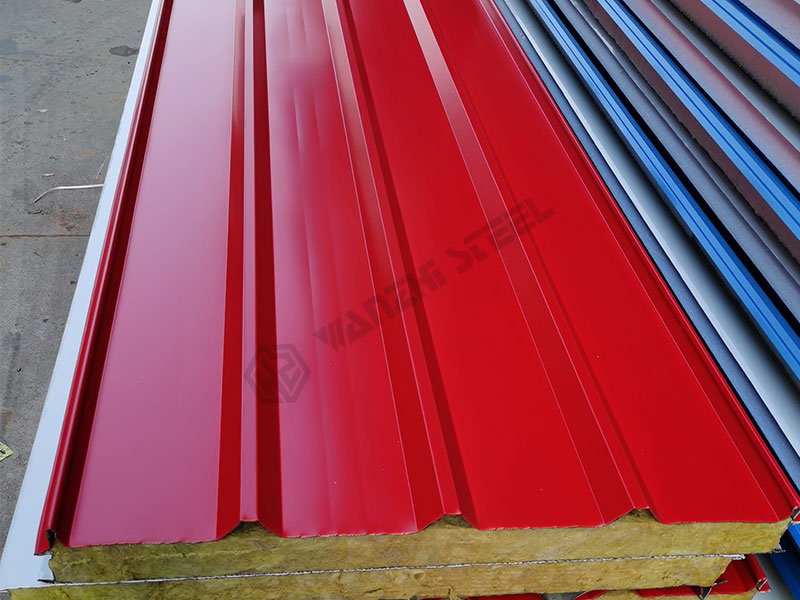

Sandwich panels, are composite structures consisting of top and bottom panels (metallic and non-metallic materials) and an intermediate core material (Core) laminated by bonding or laminating process. The design is inspired by the layered structure of a sandwich, where the panels carry the bending loads and the Core carries the shear loads, achieving high stiffness/light weight.

Sandwich Panels – Plate

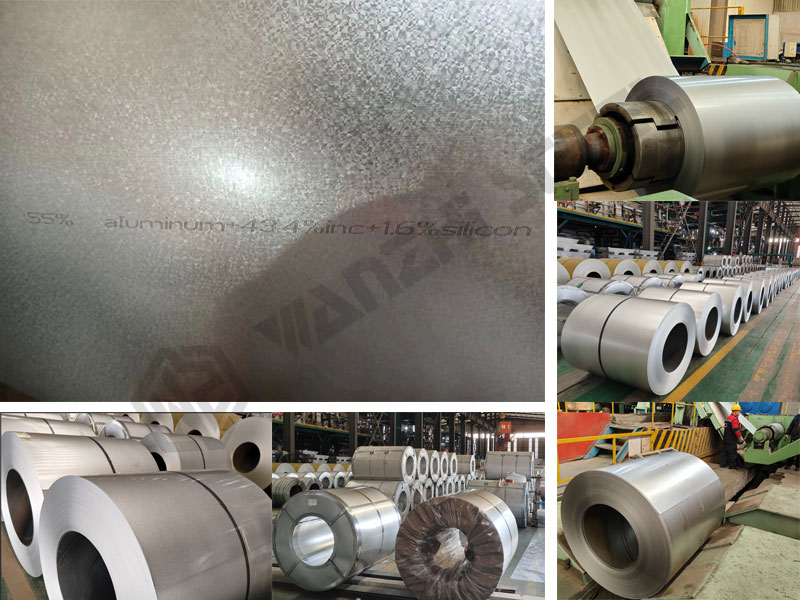

Sandwich panels are mainly divided into metallic and non-metallic panels. Popular panel materials include galvanized steel, galvalume steel, aluminum, stainless steel, painted steel, FRP (FRP), cement fiberboard and so on.

- Galvanized steel plate, color coated steel plate, aluminum plate, stainless steel plate: high strength, strong weather resistance, can be coated with decorative beauty and durability.

- Fiberglass reinforced plastic (FRP), fiber reinforced cement board: corrosion-resistant, light transmittance, insulation, special features.

Core Material of Sandwich Panel

The core material feels the core performance of sandwich panel such as heat preservation, acoustic insulation and fire prevention.

- Polyurethane (PUR): the first choice for thermal insulation, thermal conductivity of 0.022~0.025 (W/m-K), fire rating up to B1 (flame retardant).

- Rock wool (RW): the best fireproof effect, the fireproof grade reaches class A (non-combustible), the thermal conductivity is higher than polyurethane, at 0.036~0.042 (W/m-K).

- Polystyrene (EPS): the lowest cost core material, thermal conductivity 0.033~0.038(W/m-K) fire rating B2 (combustible).

- Honeycomb material: high strength, light weight, shear resistant but afraid of moisture, thermal conductivity of 0.05~0.08(W/m-K), fire class A .

- Cork/light wood: renewable/good sound insulation/low strength, thermal conductivity of 0.040~0.050(W/m-K), fire class B2 100~180

- Aerogel: fireproof, heat insulation, sound absorption and heat preservation effect is good, thermal conductivity of 0.015~0.020, fire class A.

Performance and Design

Mechanical properties:

- Bending stiffness: honeycomb core > PUR > rock wool > EPS

- Critical span (unsupported): honeycomb aluminum core (8m) > PUR (6m) > rock wool (3m)

Functionality:

- Insulation: Aerogel > PUR > EPS > Rockwool

- Acoustic insulation: Rockwool (35dB) > Cork (30dB) > PUR (25dB)

- Fire protection: Rockwool / Aerogel (Class A) > PUR (B1) > EPS (B2)

Durability:

- Weatherproofing of metal panels > Cement panels > Wood panels (anticorrosion treatment required)

How are Sandwich Panels Made?

Panel pre-treatment –> Gluing / core filling –> Hot pressing –> D-curing –> Cutting –> Edge sealing

Metal Panel Processing

Wanzhi Group has metal coil production line to produce galvanized, alloy coated, color coated galvanized, color coated zinc alloy, color coated aluminum, and other color coated aluminum, as well as provide sandwich panel processing service.

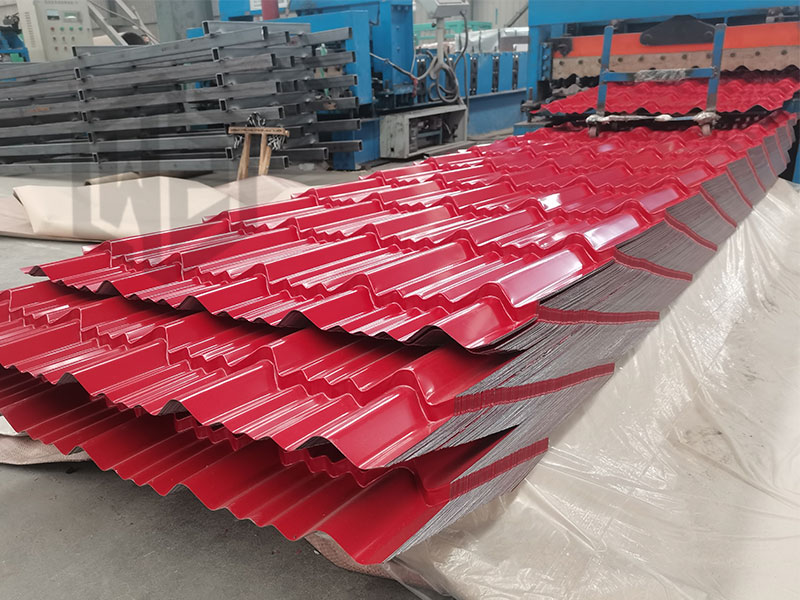

- Metal panels: Metal coated coil uncoiling → surface degreasing → roll coating with anticorrosive coating → pressing into wave/trapezoidal section.

- Non-metallic panels: Cement fiber board adopts high temperature and high pressure maintenance molding; FRP board adopts resin infiltration + glass fiber cloth lamination.

Core and panel bonding

Processed metal/non-metal panels are bonded by glue/core injection process.

- Continuous production line: high production efficiency, suitable for mass production.

- Manual bonding: low production efficiency, suitable for the production of shaped parts.

Surface treatment

- Metal panels: color coated (RAL color system), galvanized, passivated (to improve weather resistance).

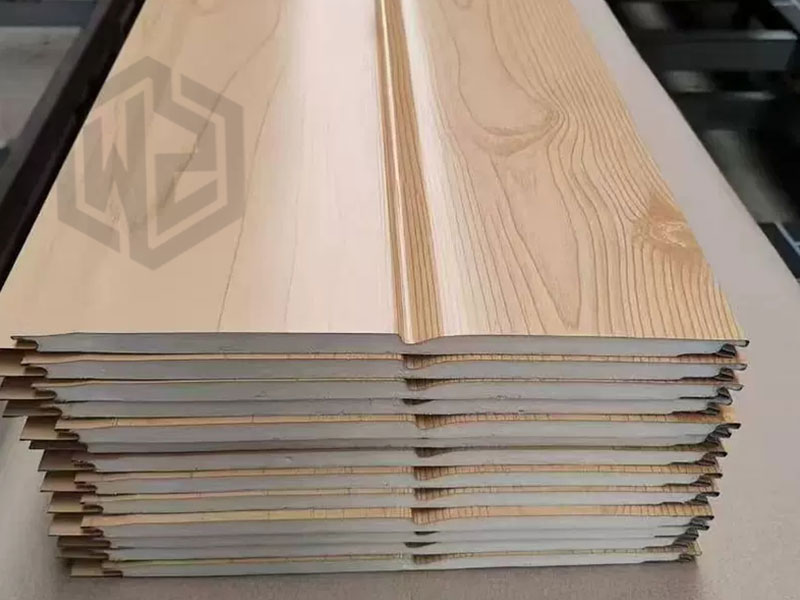

- Non-metallic panels: UV coating, laminating (anti-scratch), texturing (imitation wood grain, stone grain).

Why Use Sandwich Panels?

- Functional integration: sandwich panels can meet structural, thermal insulation, fire protection and decorative needs at the same time.

- Lightweight: panel + low density core combination, overall density can be as low as 10~50 kg/m³ (traditional concrete about 2400 kg/m³).

- Thermal insulation performance: Polyurethane/aerogel and other materials of the core material thermal conductivity as low as 0.022 W/(m-K) can reduce the energy consumption of the building, which is better than the traditional brick wall.

- Fire performance: rock wool core/cellular material can reach class A, phenolic foam core can reach 1.5 hours.

- Sound insulation performance: glass wool core can reduce noise by 30~40 dB (100mm thickness).

- Corrosion resistance: FRP panels can resist acid, alkali and salt spray corrosion, suitable for chemical and marine environments.

- Modular design: Hidden buckle, self-tapping nails, structural adhesive bonding and other connection methods support rapid assembly, reducing on-site construction time by more than 50%.

- Cuttable: Complex shapes can be processed by CNC machine tools, adapting to the needs of shaped buildings or equipment.

- Economy: Installation speed is 50% faster than traditional brick wall, saving labor and construction cost.

Where to Use Sandwich Panels?

Industrial construction

- Application: factory and warehouse, chemical workshop, hospital fireproof partition wall

- Requirements: quick construction, large span, low cost, corrosion resistance, anti-static

- Recommendation: Aluminum-zinc steel/316L stainless steel + PUR polyurethane/rock wool

Cold chain logistics

- Application: low-temperature cold storage, pharmaceutical cold chain transit warehouse

- Requirements: heat insulation

- Recommendation: aluminum alloy/stainless steel + PUR polyurethane/PIR core material

Public buildings

- Applications: airport terminals, exhibition centers, stadiums (roofing, acoustic walls), hospital operating rooms (sterile rooms)

- Requirements: wind exposure resistance, structural strength, aseptic and dust-free, etc.

- Recommendations: antimicrobial coated aluminum panels/perforated aluminum panels + rockwool core/honeycomb aluminum

Transportation equipment

- Application: High-speed rail car sidewalls, floors, ship structures, cabin partitions

- Requirements: weight reduction, salt spray resistance

- Recommendations: stainless steel/ZAM + rock wool core/PET foam

Energy and environmental protection field

- Application: photovoltaic building integration, wind turbine blade core, wind turbine canopy, solar energy rack

- Requirements: heat preservation and energy saving, good shear strength, UV resistance, sand resistance

- Recommendation: glass/wood/aluminum/color-coated steel/fiberglass reinforced plastic sandwich panels + PUR core PVC foam

Special Scene Application

- Application: explosion-proof wall, polar research station, clean room wall, ceiling

- Requirements: high strength, weather resistance, burst pressure resistance,

- Recommendation: steel plate/alloy plate/color-coated steel plate/fiberglass reinforced plastic sandwich panel + rock wool/fiber-reinforced cement/insulation panel

Emerging applications

- Applications: modular buildings (container houses), commercial building facades

- Requirements: fast installation, electromagnetic shielding

- Recommendations: galvanized steel/aluminum plates + rock wool/nickel-plated carbon fiber mats

How to Choose Sandwich Panels?

Sandwich panels are composite panels, where each combination of panel and core brings different functions and effects. The core advantages of sandwich panels are light weight, excellent performance and ease of installation. However, the cost and durability of sandwich panels vary from material to material, so you need to choose the panel and core material according to the application environment when purchasing the panels.

Requirements

- Fire protection: choose rock wool/ aerogel core

- Insulation: choose PUR/ aerogel core

Environment

- High humidity environment: Aluminum honeycomb + PUR;

- Corrosive environment: Stainless steel panel + PVDF coating.

Mechanical properties

- Large span: honeycomb aluminum core;

- High wind pressure: thickened metal panel.

Costs

- Temporary warehouse: EPS core + PE coated PPGI;

- Permanent building: PUR core + PVDF coated PPGI PPGL PPAL.

Where to Buy Sandwich Panels?

If you are purchasing large quantities and want a more cost-effective panel solution, you can either buy from a sandwich panel factory or import coils of sheet metal and process them locally. Wanzhi Group offers a wide range of sandwich panel solutions for factories, traders and distributors who require specialized raw material and finished product solutions for different applications.

Wanzhi Factory

- Qualification: ISO 9001 Quality Management System, ISO14001 + EN 14509.

- Capacity: 600,000 tons per year (guaranteed delivery).

- Customization Capability: Support non-standard sizes (e.g. curved panels, shaped cuts).

Core Certification Requirements

- Fire Safety: GB 8624/ EN 13501

- Insulation: GB/T 10295/ ISO 8301

Wanzhi Group’s galvanized sandwich panel, galvalume sandwich panel, PPGI sandwich panel, PPGL sandwich panel, metal sculptured panel are on sale, welcome to contact us.