Galvanized steel is the most widely used anti-corrosion metal material. Due to its excellent corrosion resistance and high cost-effectiveness, it is widely used in construction, home appliances, industry, agriculture, and many other fields. The coating on the surface of galvanized steel is the core of its anti-corrosion protection. However, mechanical damage such as scratches, bumps, and abrasions that occur during transportation, processing, and installation can seriously compromise the integrity of the coating and its corrosion resistance. Based on years of production experience, Wanzhi Group has compiled a maintenance guide from the perspectives of the causes of mechanical damage, immediate treatment solutions, and fundamental prevention strategies, hoping to be helpful to you.

What Causes Mechanical Damage to the Surface of Galvanized Steel?

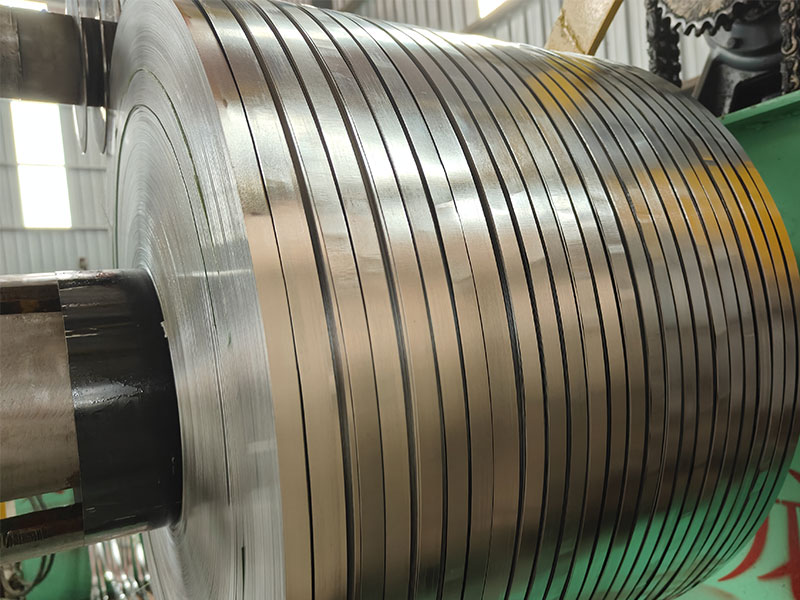

Mechanical damage to the surface of galvanized steel refers to physical damage to the zinc layer or steel base caused by external forces, commonly occurring during transportation, handling, processing, and installation.

Transportation and Loading/Unloading

- During hoisting, wire ropes or lifting equipment directly rub against or scratch the surface of galvanized steel plates or the edges of coils.

- During transportation, due to lack of secure fixing, sliding and collisions occur, resulting in scratches and dents.

- Loading and unloading equipment directly impacts the side or surface of the steel plate.

On-site Processing and Installation

- High-temperature molten slag from cutting and shearing splashes onto surrounding sheet metal, forming white oxides or small pits.

- Improper operation during drilling and punching causes the zinc layer around the holes to bulge, crack, or peel off.

- Excessive stretching during bending and forming causes fine cracks or localized detachment.

- High temperatures during welding burn away adjacent zinc layers, creating unprotected areas.

Storage and Stacking Management

- Indentations occur at the bottom during storage.

- Insufficient space between galvanized sheets leads to mutual friction.

- Accidental falling heavy objects damage the surface.

What to do About Mechanical Damage to Galvanized Steel Surfaces?

When mechanical damage of varying degrees is found on the surface of galvanized steel, first determine whether repair is worthwhile. Minor damage can be treated locally with zinc plating to prevent rust from spreading. If the damaged area is too large, replacement is necessary.

Minor Damage

Scratches or small areas of zinc layer wear, but without exposing the steel substrate, constitute minor damage (the base color remains the silvery-white or grayish-white of zinc). Clean the damaged area and surrounding area, then apply a specialized galvanized layer repair and passivation agent.

Severe Damage

Deep scratches, zinc layer peeling, exposed steel substrate, and weld spatter are present. If continued repair is desired, two approaches can be taken.

- 1. Remove rust, loose zinc, and impurities from the damaged area. Apply a zinc-rich coating evenly to the exposed area, applying at least two coats.

- 2. After cleaning surface scratches and rust, apply epoxy anti-rust paint to provide a protective barrier for the galvanized steel. For large areas of mechanical damage or severe damage, we recommend replacement, as repair costs are higher.

How to Avoid Mechanical Damage?

Most mechanical damage to galvanized steel surfaces is avoidable. Systematic preventative measures are the most effective way to ensure the integrity of galvanized steel products!

- Optimized Packaging: In addition to flexible spacers (such as plastic film and kraft paper), wooden pallets/metal trays can be added between sheet materials; for coils, steel guard plates should be added to protect the sides, and they should be securely bundled with steel straps.

- Scientific Loading: Use specialized lifting tools (such as lifting slings and C-hooks) to avoid direct contact between steel wire ropes and the product.

- Storage Area: The storage area should be flat, firm, and free of standing water; galvanized sheets should be placed horizontally, and galvanized coils should be stacked properly, controlling the stacking height to avoid compression and deformation.

- Protective Measures: Separate the processing area from the storage area to prevent accidental damage to the galvanized material from other operations (such as welding and grinding).

- Refined Processing: Use appropriate tools, protect the surrounding area during cutting and welding, and process the substrate according to its mechanical properties. Supplier: Choose a galvanized steel supplier with comprehensive quality management and professional service capabilities.

While mechanical damage to galvanized steel surfaces is difficult to completely eliminate, its impact can be minimized through prevention and repair. Wanzhi Group not only provides high-quality galvanized steel but is also committed to providing customers with full-cycle value services covering product protection and processing guidance! Contact us for solutions and quotes!