| PE | Interior decoration, appliance panels |

| SMP/HDP | Outdoor roofing/curtain walls |

| PVDF | Seaside/industrial corrosive environments |

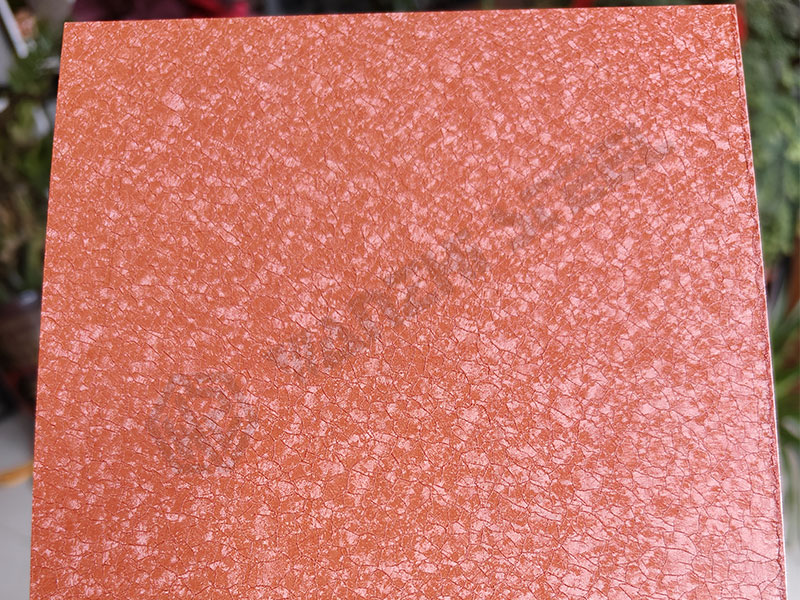

What are Textured PPGI Coils?

Textured PPGI Coils (Textured Pre-Painted Galvanized/Glume Coils) is a kind of color coated steel sheet with specific texture on the surface, which is made of galvanized (GI) or galvanized-luminescent (GL) steel sheet, and then coated with organic coatings (e.g., PE, SMP, PVDF, HDP, PU) to form decorative textures such as wood grain, stone textured, leather textured, diamond, etc. through embossing process. The texture depth, color, and surface effect can be designed and produced according to the application area.

PPGI substrate types

- Galvanized steel: Cold rolled steel + pure zinc coating.

- Galvalume steel: Cold rolled steel + zinc-aluminum alloy coating (55% Al + 43% Zn + 1.6% Si).

PPGI coating type

- Primer: Epoxy resin

- Top Coat: Polyester Coating, Silicon Modified Polyester, High Weather Polyester, Fluorocarbon Coating.

PPGI Texture Type

- Diamond, Stripe, Leather grain texture

- Wood/stone-like texture

- 3D effect, customized digital pattern

PPGI Color Standard

- RAL color card, Pantone color card, or according to customer’s sample color mixing.

PPGI surface effect

- Matte, bright, etc.

Textured PPGI Coils for sale

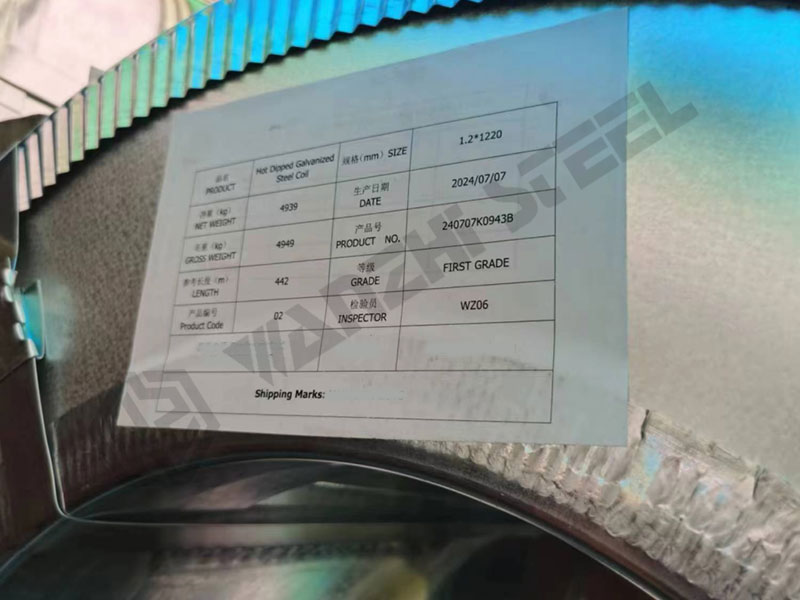

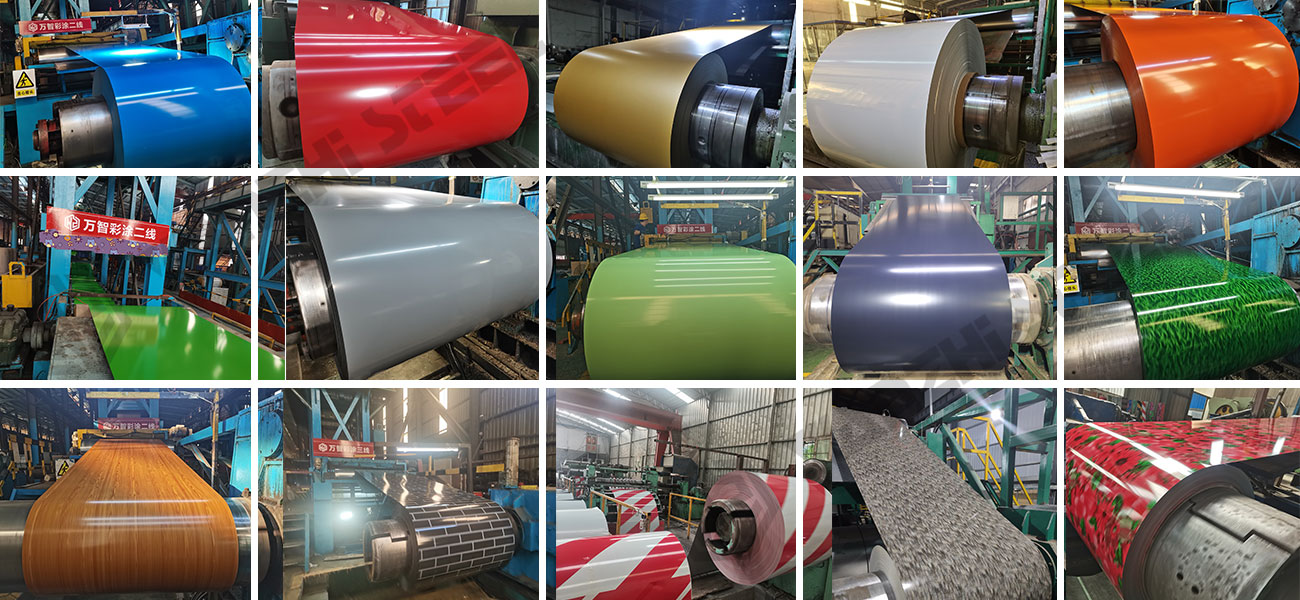

Textured PPGI Coils are one of Wanzhi Group’s popular PPGI steel products. We also produce Matt PPGI coil, glossy PPGI coil, pattern design PPGI, etc., in accordance with the national standards of ASTM, JIS, GB, EN, ISO, etc.

Specification

| Grades | GI/GL/SPCC/SPCD/SPCE/DC01-DC07/Q195、Q215、Q235 |

|---|---|

| Colors | Top/Back:RAL,Painted steel,3D Painted steel, etc(can be customized) |

| Thickness | 0.12-1.5 mm |

| Width | 600-1250mm/ customized |

| Coil Weight | 3-6 tons/ customized |

| Substrate Type | Hot dip galvanized, Galvalume, Zinc alloy, Cold rolled steel, Aluminum-zinc plated steel,Zimalium |

| Zinc Coating Thickness | Z30-275g/ ㎡,AZ30-150g/ ㎡ |

| Introduction to Coating | PVDF、HDP、SMP、PE |

| Coating Thickness | Top :10-40 um,Back:5-20 um |

| Inside diameter | 508/610mm |

| Package | Standard export package or as per your requirements |

| Certificates | SGS, ISO 9001,CE |

| Date of Delivery | 5-45 days |

Textured PPGI Customized

Solution

Wanzhi’s solutions for global construction and industrial projects include roof panel processing, greenhouse projects, guttering production, suspended ceilings, wall panel processing, appliance panels production, etc.

Wanzhi Steel – Agricultural Greenhouse Project in Turkmenistan

550 tons PPGI Steel Coil to Azerbaijan

100 tons of Galvanized Coils to Saudi Arabia

144 ton Steel Wire to Spanish

Project of PPGI Roofing en Libya

100 tons of GL and PPGL in Solomon Islands

Textured PPGI Coils Features and Applications

Textured PPGI Coils combine the mechanical and physical properties of galvanized steel, coatings, and the decorative qualities of different textured designs, making it an ideal solution for architectural, appliance, and automotive applications.

Core Benefits

- Highly decorative: a wide range of colors (supported by RAL, Pantone), wood, stone, leather, and other textures are available to meet individual design requirements.

- Weathering and durability: PVDF coating has a service life of up to 20 years or more in coastal or high UV areas, and it is UV resistant, anti-chalking, weathering, and other characteristics.

- Scratch and abrasion resistance: The Surface texture can hide minor scratches, and the embossing process enhances abrasion resistance.

- Environmentally friendly: Complies with RoHS and REACH standards.

Applications

- Building facades and curtain walls

- Roofs and walls of residential, commercial, and industrial buildings.

- Prefabricated houses, containerized houses

- Factory warehouses, freezers

- Road signs, billboards

- Fences, Building Enclosures

- Doors, Windows, Shading

- Greenhouse Frames, Exterior Covers, etc.

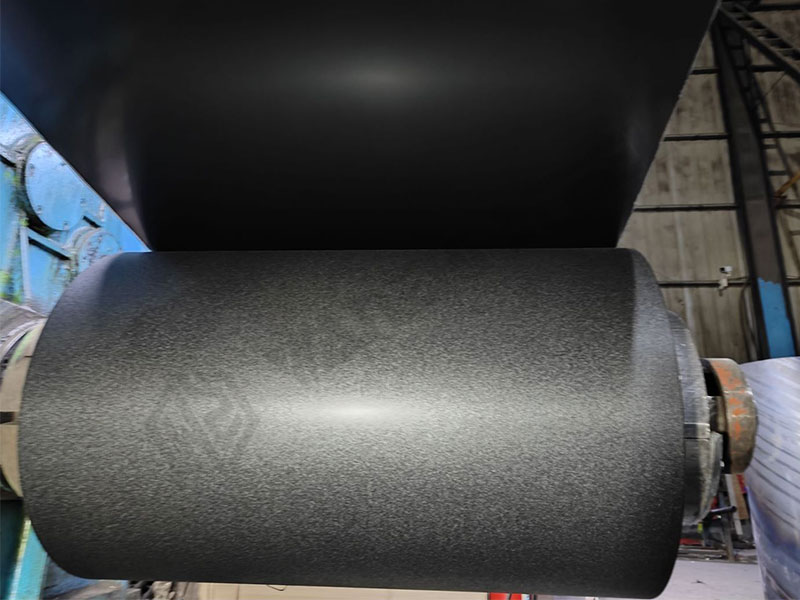

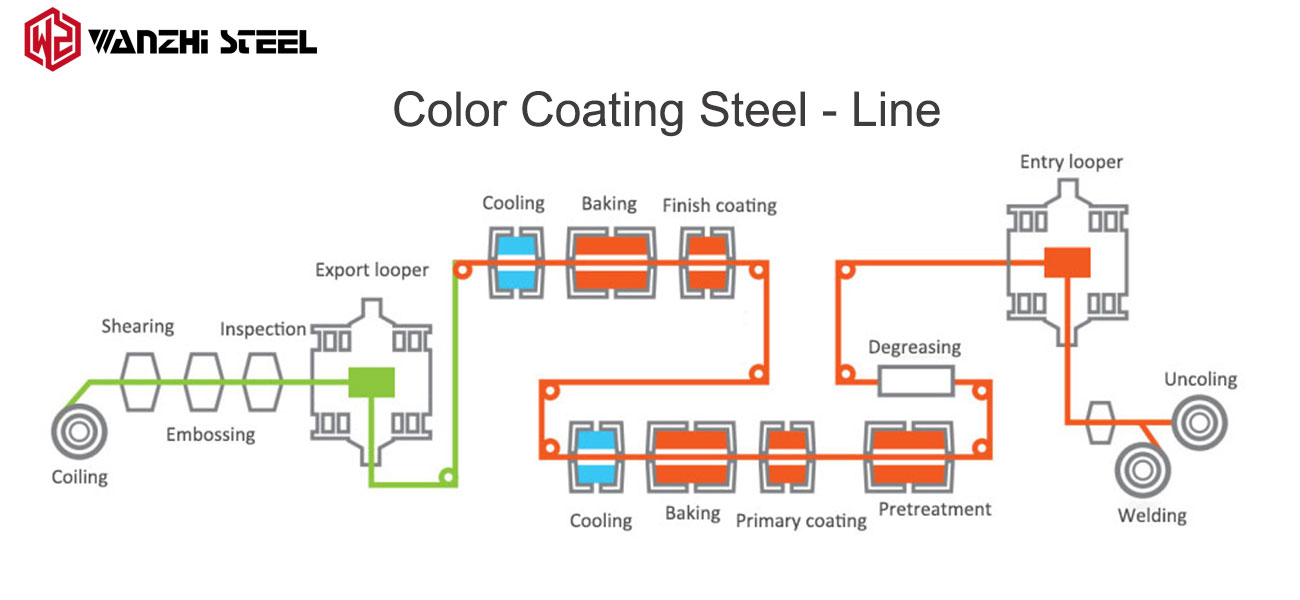

Textured PPGI Coils Production Process

Substrate treatment: Select galvanized steel with a zinc layer weight of 60-275 g/m2 (both sides) as the raw material and clean it with an acid-base solution with a pH of 9-11.

Chemical conversion layer: A chemical conversion layer with a thickness of 0.5-3 microns is applied by phosphating or passivating the shape.

Paint: Primer is applied with epoxy resin or polyester, the top coat is applied with organic paint, and a paint layer is formed on the surface of the substrate (GI steel) by roller coating.

Embossing: Mechanical embossing (for PPGI with textures such as diamonds, stripes, leather), coating bionics (for PPGI with textures such as wood/stone), and composite lamination (for PPGI with 3D effects).

Baking and curing: PMT220-240℃, 30-60 seconds.

Cooling: PPGI coil cooled to below 40℃, start to take the coil.

Deep processing: This can be slitting, bending, stamping, molding, and other deep processing.

Textured PPGI Sourcing Suggestion

Textured PPGI steel surface not only enhances the decorative features but also hides scratches and enhances abrasion resistance. Wanzhi Group has compiled a list of Textured PPGI coils solutions for various applications, which we hope will be helpful for you to purchase PPGI.

Texture Selection by Application

- Architecture: wood grain, stone grain

- Appliances: High-gloss, matte, solid colors, geometric textures

- Transportation: Leather, Brushed

- Commercial: Metallic, 3D Textures

Selection of coatings according to the environment

- Corrosive areas: PVDF coating

- General outdoor: SMP/HDP

Combine the strength of the supplier to choose the cooperation object

- Before formal purchase, you can ask the supplier for samples for salt spray resistance and color difference tests.

- After the order production is completed, you can also sample the products for quality inspection. Suppliers need to cooperate with SGS, BV, and other third-party inspection organizations to complete the quality inspection.

- Checking product quality, service, customer feedback, certificates, customer feedback, etc., are all effective ways to screen PPGI suppliers.

Textured PPGI Coils Factory

Wanzhi PPGI factory is certified by ISO9001, ISO14001, etc. With an annual production capacity of 600,000 tons, our production line is capable of producing PPGI coils in various sizes, colors, styles, and surface effects. In addition, we also provide additional services such as bending, slitting, stamping, punching, profiling, and so on. If you need samples or have a plan to visit the color coating factory, please get in touch with us at info01@wanzhisteel.com.

Textured PPGI Coils and Sheets Use and Maintenance

- Keep the humidity of the storage environment below 70%.

- Use professional tools to avoid damaging the coating.

- Regularly clean the surface of Textured PPGI Coils and Sheets with cleaning agents.

- Regularly check the integrity of the coating and repair the coating if any peeling phenomenon occurs.