Depending on carbon content, alloying elements, yield strength, yield strength, elongation, forming properties, etc., deep-drawing galvanized steels can be classified as ordinary deep-drawing galvanized steels SGCD3, DX53D, CS Type D, DC53D, ultra-deep-drawing galvanized steels SGCD4, DX54D, SS Grade 40, DC54D, extra-deep-drawing galvanized steels SGCD5, DX56D, and many others. There are many types of galvanized steel.

What is Deep-Drawing Galvanized Steel ?

Deep Drawing Grade galvanized steel is a galvanized steel sheet designed for extreme drawing and forming processes, with the advantages of high ductility, uniform plastic deformability and coating adhesion.

| Performance Indicator | Requirement |

| Plastic Strain Ratio (r) | ≥1.8 (the higher, the better) |

| Strain Hardening Index (n) | ≥0.20 |

| Elongation (A80mm) | ≥38% |

| Coating Adhesion | No coating detachment after 8mm ball punch tensile test |

| Aging Stability | Ultra-low carbon (C ≤ 0.01%) + Nitride fixation |

What are the Grades of Deep-Drawing Galvanized Steel ?

Currently the popular international standards of GI steel are Japanese Standard JIS G 3302, European Standard EN 10346, American Standard ASTM A653, National Standard GB/T 2518, and so on.

| Grade | Characteristics |

| SGCD3 | General deep drawing grade (r ≥ 1.5) |

| SGCD4 | Extra deep drawing grade (r ≥ 1.8, n ≥ 0.20) |

| SGCD5 | Special deep drawing grade (r ≥ 2.0) |

| DX53D | DDC, standard deep drawing grade (rₘ ≥ 1.8) |

| DX54D | DDD, extra deep drawing grade (rₘ ≥ 2.0, nₘ ≥ 0.22) |

| DX56D | EDDS, special deep drawing + aging resistance |

| CS Type D | DDSK, deep drawing grade |

| SS Grade 40 | EDDS, structural deep drawing grade |

| DC53D | DX53D, general deep drawing |

| DC54D | DX54D, extra deep drawing |

Classification of Deep-drawn Galvanized Steel

According to the standard and origin, it can be classified into JIS deep-drawn galvanized steel, ASTM deep-drawn galvanized steel, EN deep-drawn galvanized steel, and so on, and the galvanized steel of different standard grades has differences in formability, weldability, and corrosion resistance, and so on. In addition to standard and origin, common classifications include material and properties.

Categorized by Material and Properties

Cold Rolled Carbon Steel Sheets and Strips for Deep Drawing

- Grade: DC05, DC06

- Characteristics: Galvanized from cold rolled steel substrate with very low carbon content and optimized alloying element ratio, giving it excellent deep drawing properties.

- Applications: automotive, home appliances, construction, etc.

Hot-dip galvanized steel sheet for deep-drawing

- Grade: DX51D+Z, DX52D+Z

- Characteristics: A zinc layer is formed on the surface of the steel sheet by hot-dip galvanizing process on the surface of the cold rolled steel, which improves the corrosion resistance of the steel.

- Applications: Deep-drawn parts that require corrosion resistance, such as structural parts for automobiles and home appliances.

Electro Galvanized Steel Sheet for Deep Drawing

- Grade:SECC, SECD

- Features: A zinc layer is deposited on the surface of the steel sheet through the electro galvanizing process, which provides a uniform coating thickness and good surface quality.

- Applications: Deep-drawn parts for automobiles, home appliances, electronic equipment, etc., which require high surface quality.

Classification by Special Properties

High Strength Deep Drawing Grade Galvanized Steel

Features: High tensile and yield strengths while maintaining excellent deep drawing properties. This type of steel achieves a balance between strength and formability by adding alloying elements and optimizing the heat treatment process.

Ultra-deep-drawing grade galvanized steel

Characteristics: Extremely high deep-drawing performance enables the manufacture of complex shaped parts without cracking. This type of steel achieves ultra-deep-drawing performance by controlling the carbon content, adding alloying elements, and optimizing the rolling process.

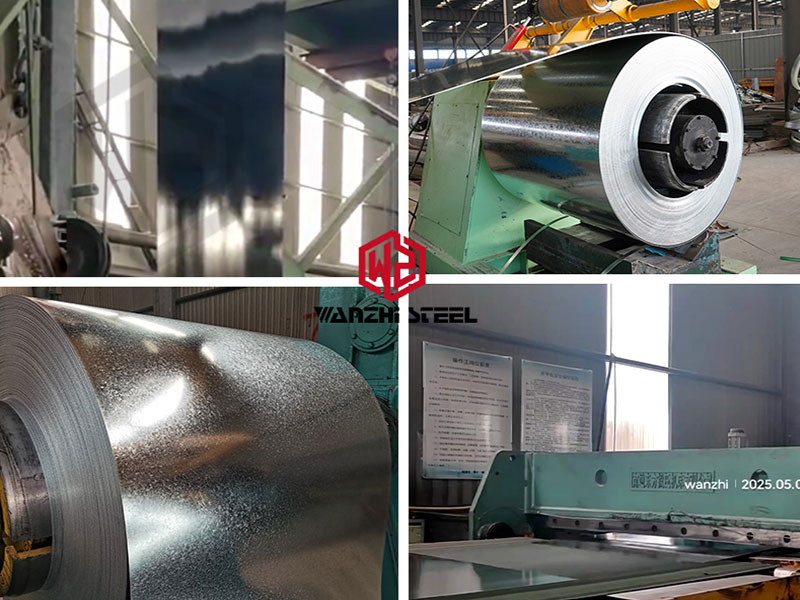

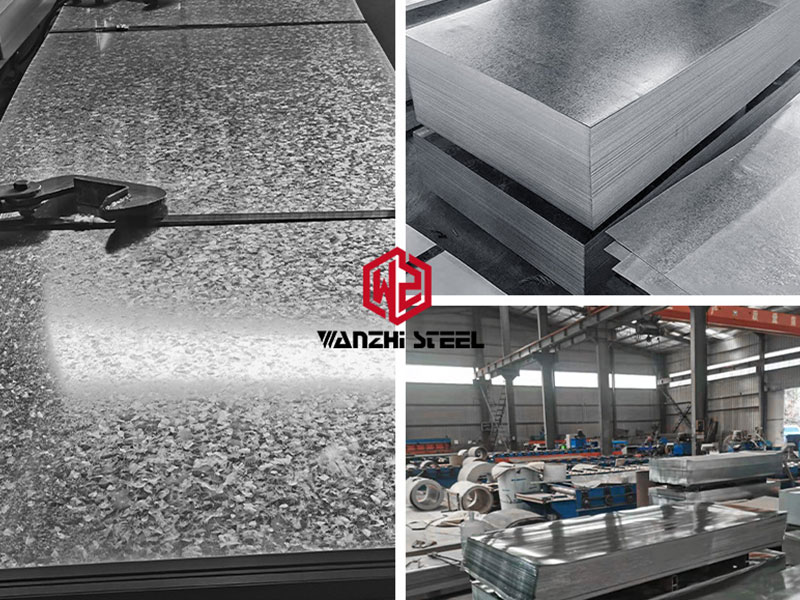

Buy Deep Drawing Grade Galvanized Steel

When buying deep drawing grade galvanized steel, in addition to the supplier and price, we should consider the deep drawing performance, corrosion resistance, strength and other requirements of the steel from the application scenario, and choose the grade of substrate material and zinc thickness according to the application requirements, and make sure that the yield strength, tensile strength, elongation and other requirements of the steel are in line with our processing requirements. If you already have a purchase plan, Wanzhi Group can produce according to your requirements, if you have application needs, Wanzhi Group can provide OEM ODM services, welcome to contact us for a free quote.