Aluzinc steel, as a modern engineering material, has become the preferred metal choice across numerous sectors—from building materials and home appliance manufacturing to infrastructure applications—due to its unique structural support, decorative appearance, and corrosion resistance ranging from mild indoor environments to harsh outdoor conditions. Explore the applications of Aluzinc steel with Wanzhi Group, examining everything from sheet surface treatments to coating thicknesses—whether for standardized products or deep customization!

Surface Conditions

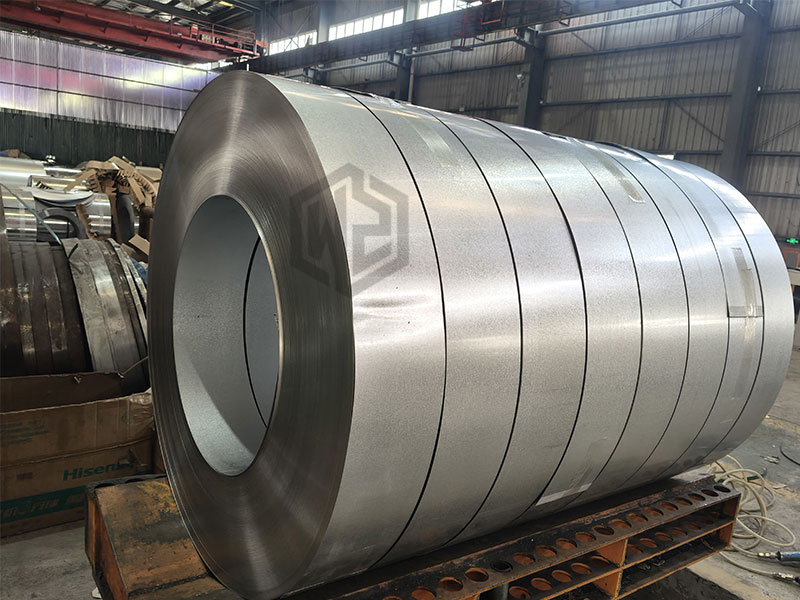

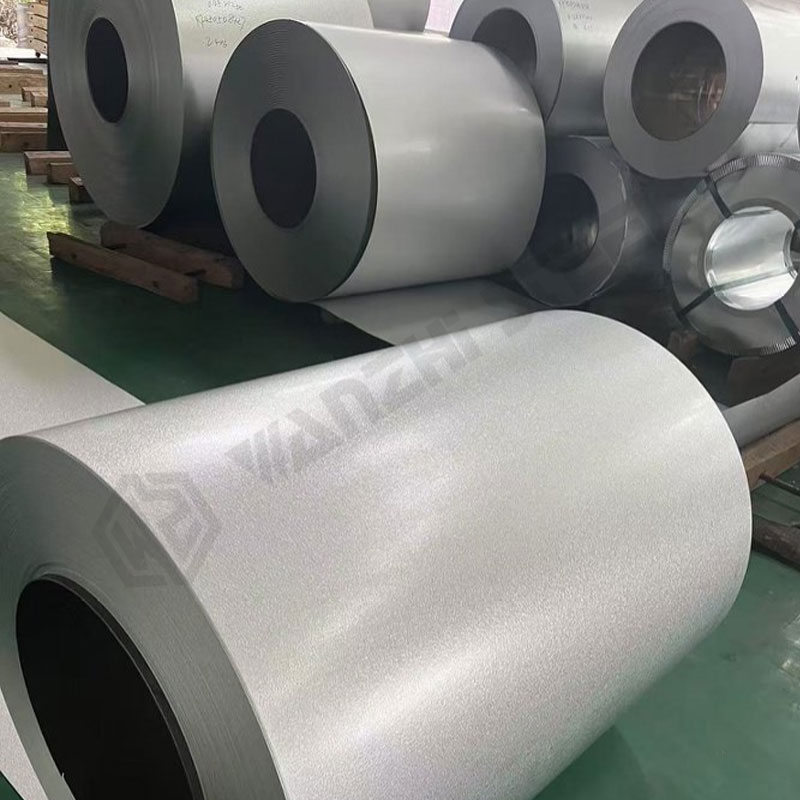

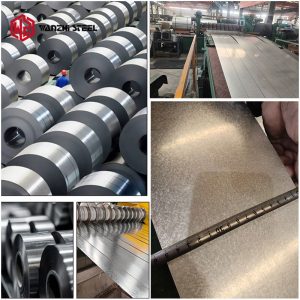

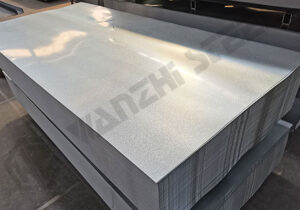

Currently, Wanzhi Group offers Aluzinc products including: Aluzinc Coil, Aluzinc Strip, Aluzinc Sheet/Plate, Aluzinc Profiled Panel, and Prepainted Aluzinc (PPGL). Our factory also provides deep processing services. Different surface treatment processes endow it with diverse functional and aesthetic values, directly expanding its applications.

Aluzinc in Basic Corrosion Protection State (Bare Coated/Passivated): Retains its distinctive silver-gray matte fishscale pattern at the lowest cost. Widely used for concealed construction, structural supports, or as a premium substrate for further processing.

Fingerprint-resistant Aluzinc: Features superior stain resistance and easy cleaning. Designed for products requiring frequent handling or pristine appearance, such as high-end appliance control panels, server cabinet interiors, and medical equipment housings.

Pre-coated (color-coated) substrate: Enhanced decorative appeal and weather resistance through coatings like PE polyester, HDP high-durability polyester, or PVDF fluorocarbon. Color-coated Aluzinc (PPGL) is widely used in high-end architectural curtain walls, modern home panels, and branded signage components, achieving a perfect balance of protection and aesthetics.

Application Areas

Aluzinc steel has replaced GI steel as a popular choice across numerous industries due to its superior corrosion resistance and excellent processing characteristics.

Construction Sector: The most extensive application domain, primarily used for roofing and wall cladding systems, as well as light-gauge steel framing and purlins in building structures. Aluzinc’s outstanding weather resistance and long-term durability perfectly align with the construction industry’s need to ensure structural integrity while withstanding decades of exposure to wind and rain.

Home Appliances & High-End Manufacturing: Another significant application area. Aluzinc delivers reliable corrosion protection, while its clean, smooth surface and excellent formability meet stringent requirements for aesthetics and precision manufacturing. This ranges from refrigerator and washing machine shells and liners to air conditioner outdoor units, charging station enclosures, and various electrical control cabinets.

Transportation and Industry: A common domain for Aluzinc. Its heat resistance, lightweight properties, and high strength provide stable, long-term protection in automotive, trailers, containers, logistics enclosures, chemical processing, agriculture, and photovoltaic industries.

Environmental Impact

Consistent performance across diverse environments is the primary reason for Aluzinc’s popularity. We offer a complete coating series ranging from AZ30 to AZ150 aluzinc to match various corrosion environments.

Indoor or Dry Mild Environments: For applications like appliance internal components or indoor shelving in arid regions, Aluzinc AZ30 (30g/m²) provides a cost-effective solution. It ensures fundamental corrosion protection while maximizing cost control.

Industrial and General Outdoor Environments: For applications like inland factory enclosures and general photovoltaic mounting structures, Aluzinc AZ50 (50 g/m²) achieves the optimal balance between performance and cost, representing the most cost-effective choice.

High humidity, mild salt spray, or industrial atmospheric environments: For coastal buildings or peripheral facilities in chemical industrial parks, heavy-duty corrosion protection like AZ100 (100g/m²) becomes essential. Its extra-thick coating delivers ultra-long-term asset protection.

Severe coastal corrosion zones or specific chemical environments: For applications like port machinery protective panels and offshore aquaculture facilities, AZ150 (150g/m²) and higher grades establish the ultimate corrosion barrier.

Aluzinc – Products

As a factory with a complete coating industrial chain, Wanzhi Group not only offers a full range of Aluzinc products in all states but also provides one-stop technical support for customers with diverse needs—from material selection and cost optimization to processing and forming. Contact us anytime for solutions and a free quote!