PPGI Sheet is a sheet metal material produced by slitting PPGI coil into specific lengths. It offers excellent workability, enabling processes such as stamping, punching, and forming. The functional coating on the sheet surface provides outstanding environmental adaptability, maintaining stable performance in conditions including rain, snow, high temperatures, high humidity, salt spray, and chemical exposure.

Classified by Application Industry

As a corrosion-resistant metal material, PPGI sheet plays a vital role in construction, home appliance manufacturing, automotive, advertising, and other industries.

Construction

This is the most common application for colour-coated steel sheets, used for roofing, wall cladding, ceilings, suspended ceilings, building envelopes, and more.

- Industrial Buildings: Factories, manufacturing plants, and workshops.

- Commercial Buildings: Shopping malls, supermarkets, warehouses, and logistics centers.

- Agricultural Buildings: Farm sheds, livestock barns, and greenhouses.

- Public & Recreational Facilities: Stadiums, airports, train stations, and exhibition halls.

- Residential Buildings: Roofs, fences, and gates for homes.

- Decorative Applications: Partitions, ceilings, gutters, ductwork, etc.

Home Appliances

PPGI Sheet serves as a key material for many home appliance housings and internal components due to its excellent formability and aesthetically pleasing surface finish.

- Major Appliances: Refrigerators, washing machines, air conditioners, microwaves, dishwashers, and water heaters.

- Small Appliances: Electric ovens, rice cookers, and range hoods.

Automotive Industry

While PPGI is unsuitable for vehicle body panels, it is frequently used in components requiring corrosion resistance and high-quality surface finishes.

- Interior components: Dashboard frames, door inner panels, and seat frames.

- Underbody components: Fuel tanks, brake systems, and brackets.

Furniture and Interior Decoration

The diverse colors and textures of PPGI sheet make them highly popular in modern furniture and interior design.

- Office and Home Furnishings: Cabinet fronts, bookshelves, and desks.

- Partitions: Suspended ceilings, modular partitions for offices and residences.

- Decorative Panels: Wall art and accent walls.

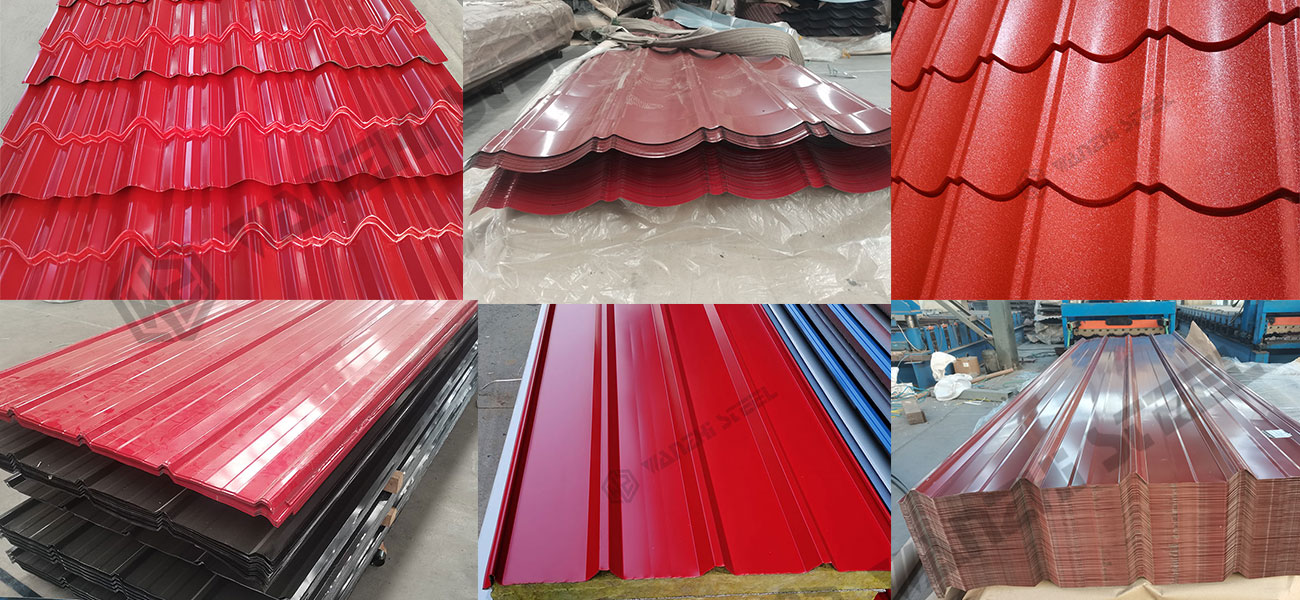

Classification by Panel Type

Formed PPGI sheets feature diverse surface textures and cross-sections, delivering aesthetic appeal, corrosion resistance, structural rigidity, drainage, and wind pressure resistance during application.

PPGI Hidden-Fix / Cassette Panel

Profile Features: Secured via clips or specialized fasteners, with completely concealed fixings. Creates a seamless, wide-panel effect for a modern, clean appearance.

Applications:

- High-end commercial building exteriors: Office towers, shopping malls, airports, stadiums, and other public structures demanding exceptional aesthetics.

- Interior premium finishes: Lobby walls, ceilings, partitions, etc.

PPGI Trapezoidal / Standing Seam Roof Panel

Profile Characteristics: Features a high rib height with a distinct trapezoidal cross-section, delivering exceptional strength. Standing seam panels are a variant of trapezoidal panels, mechanically interlocking their vertical edges.

Applications:

- Roofing for large industrial and commercial buildings: Primary waterproofing layer for main roofs of large-span structures like factories, logistics warehouses, and supermarkets.

- Roofing for public buildings: Train stations, sports stadiums, etc.

Corrugated Panel (PPGI Corrugated Panel)

Profile Characteristics: Traditional wavy arc with relatively low wave height. The most classic and common profile.

Applications:

- Walls and roofs: Agricultural structures (grain silos, livestock sheds), warehouses, workshops, guesthouses, gatehouses, etc.

- Retro-style architecture: Achieving traditional or industrial aesthetics.

Tile Panel (PPGI Tile Panel)

Profile Characteristics: Mimics the shape and texture of traditional clay or slate tiles, but constructed from lightweight color-coated steel.

Applications:

- Roofing for high-end residences and villas: Projects seeking the aesthetic appeal of traditional tiles while prioritizing lightweight construction, durability, and rapid installation.

- Roofing for resorts, commercial streets, and other structures requiring specific architectural styles.

PPGI Micro-Rib Panel

Profile Characteristics: Features extremely fine, low-profile longitudinal corrugations or textures (wave height only 1-3mm).

Applications:

- Building Facades: Commonly used as wall panels for industrial or commercial buildings, providing a sleek, modern visual effect.

- Interior Decoration: Suitable for partitions, ceilings, and similar applications.

By Coating Performance

The material and film properties of organic coatings determine the durability and environmental suitability of PPGI. Currently popular organic coatings include: epoxy resin, polyester, silicone-modified polyester, high weatherability polyester, fluorocarbon, etc. Coating Structure: 2/1, 2/2, etc.; Film Thickness: Topcoat 10-40 microns, Primer 5-20 microns.

Polyester (PE) – Standard Weather Resistance

- Applications: Indoor appliances, furniture, interior partitions, or non-corrosive general industrial building walls.

Silicone-Modified Polyester (SMP) – Medium Weather Resistance

- Applications: Roofs and walls of most industrial plants and warehouses, offering excellent cost-performance.

High Durability Polyester (HDP) – High Weather Resistance

- Applications: Commercial buildings and residential projects demanding superior color and gloss retention.

Polyvinylidene Fluoride (PVDF) – Superior Weather Resistance

- Applications: High-end projects in extreme environments such as landmark buildings, coastal regions, and areas with intense UV exposure.

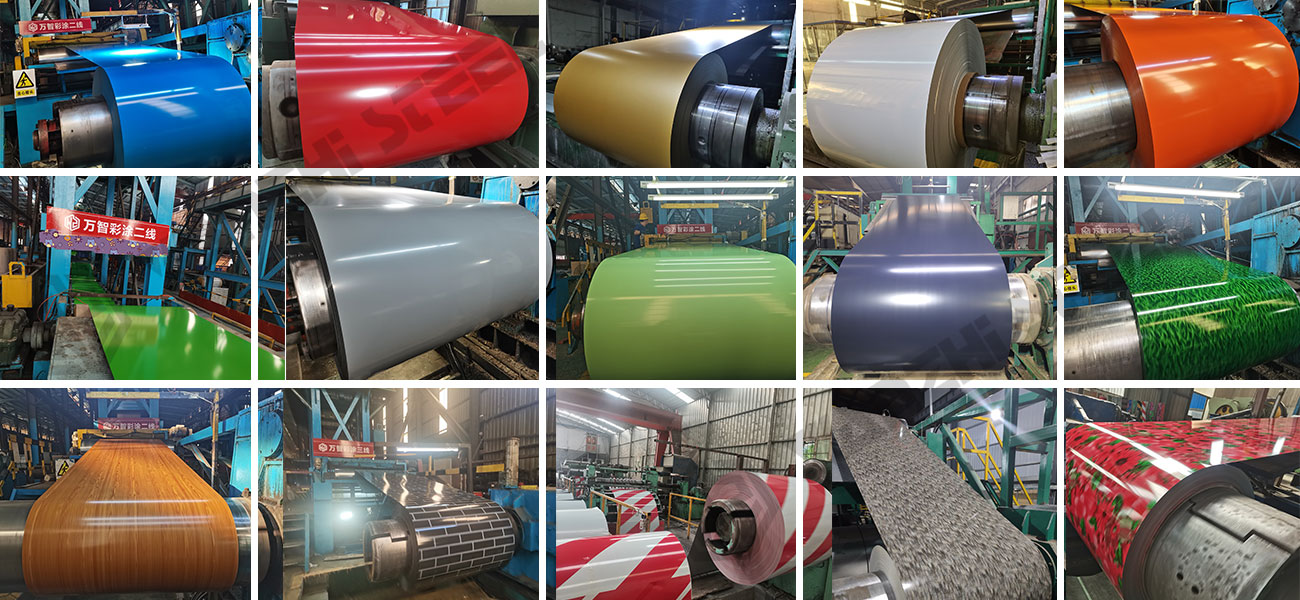

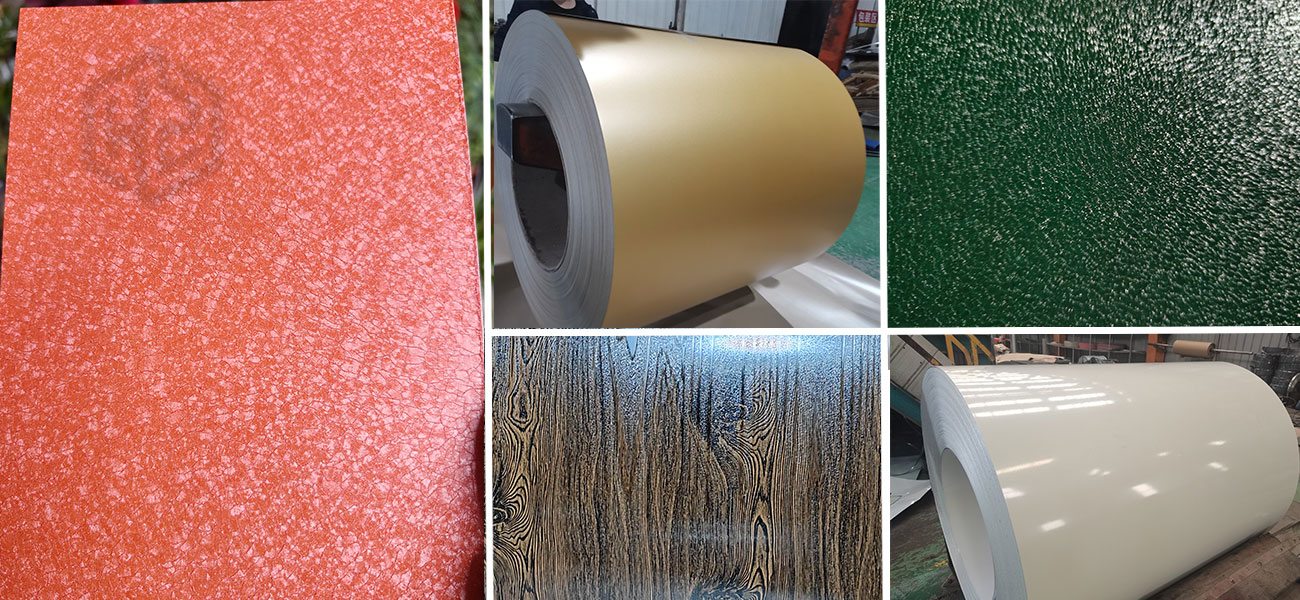

By Surface Finish

PPGI’s extensive range of colors and patterns meets aesthetic and specialized functional demands, widely used in premium curtain walls, home decor, and natural material simulations.

- Color: Solid, metallic, and special effect colors.

- Gloss: High gloss (>70%), semi-gloss (30-70%), matte (<15%).

- Texture: Smooth flat, orange peel, sand grain, wood grain, stone grain, embossed, etc.

By Special Function

Wanzhi Group’s functional PPGI sheets developed for specific requirements.

- Anti-bacterial: For hospitals, food processing plants, and kitchen equipment.

- Self-cleaning: For tall buildings where cleaning is difficult.

- Thermal Reflective: Reflects sunlight to reduce building energy consumption, used for roofing in hot regions.

- Hard & Scratch-resistant: For high-friction applications like appliance panels and furniture.

What PPGI steel projects are you planning? Simply share your application requirements, and Wanzhi Group will tailor a customized PPGI solution for you! Contact us today for a free quote!