PPGI steel coil full form is prepainted galvanized iron coil, also known as color-coated GI steel coils, is galvanized steel as the substrate after degreasing, cleaning, phosphating, and other surface finish, and then rolled in the surface of the steel with one or more layers of organic coatings and become color coated. steel coils. Due to its excellent corrosion resistance, durability, and wide range of colors and finishes available, it is a popular solution for roofing panels, wall panels, appliance panels, writing boards, automotive manufacturing, ductwork furniture, and decorative applications.

What is the PPGI Steel Coil Used for?

PPGI steel coil combines the corrosion protection of galvanized coating with the aesthetics of painted coatings and plays an important role in construction, infrastructure building, appliance manufacturing, automotive manufacturing, new energy, agriculture, and more.

PPGI Steel Coils in Appliance Manufacturing

Refrigerator, washing machine, microwave oven housings

Air conditioners, dishwasher housings

PPGI Steel Coils in Construction

Roof coverings: roof sheets, roof tiles, sandwich panels

Wall cladding: facades, wall panels

Decoration: Ceilings, Suspended ceilings, Decorative walls, Acoustic walls, Partitions.

Other buildings: industrial plants, greenhouses, etc.

PPGI Steel Coils in automotive manufacturing

Body shells, Automobile interior parts, Doors, Roofs.

Ships, airplanes.

PPGI Steel Coils in the Power and Energy Sector

Electricity: wires, cables, power racks, power equipment.

Energy: solar racks, solar energy

PPGI steel coils in transportation facilities

Traffic signs, guardrails, road barriers, etc.

Other applications

PPGI writing boards, PPGI gutters, ventilation ducts, closets, shelves, mobile homes, etc.

Why Choose PPGI Steel Coil?

PPGI steel coil is the ideal raw material solution for residential and industrial applications, PPGI has the advantages of aesthetics, durability, corrosion resistance, weatherability, cost-effectiveness, versatility, etc. By bending, forming, and cutting, it can be processed into PPGI sheets, PPGI panels, PPGI roofing/walls, PPGI strips, PPGI pipes, etc. Both construction and industrial applications bring high economic benefits.

Coating Protection

PPGI coil and sheet are protected by galvanized and colorful paint coatings that not only enhance the steel’s corrosion resistance and durability but also improve its appearance by providing UV and weather resistance.

Aesthetics

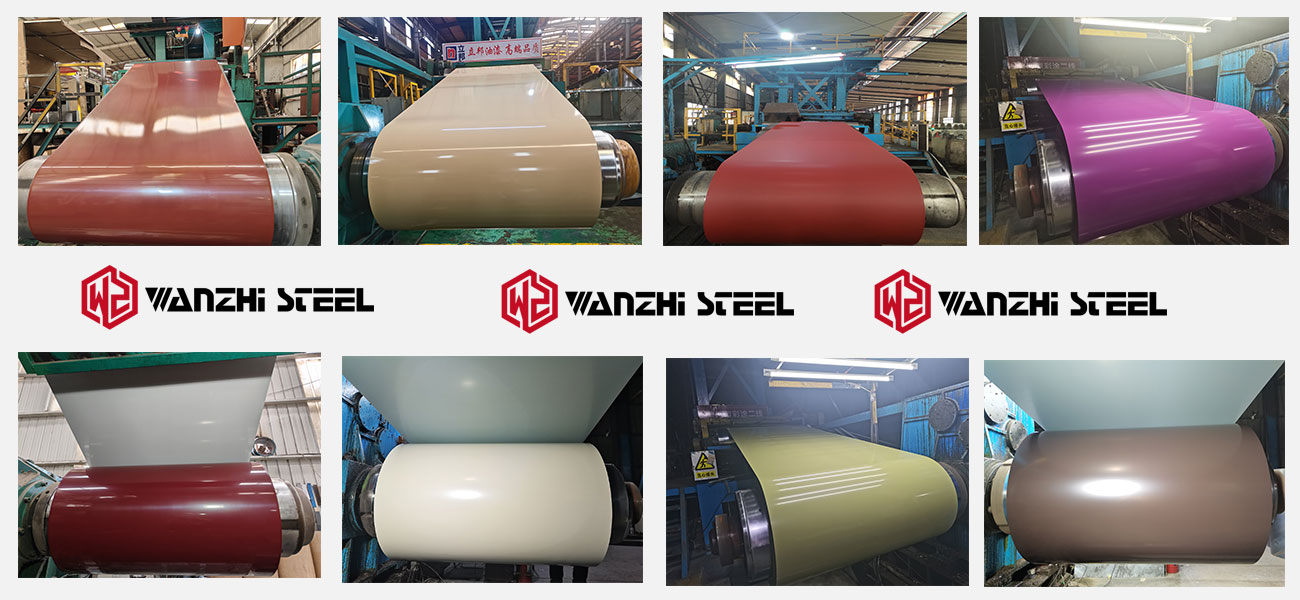

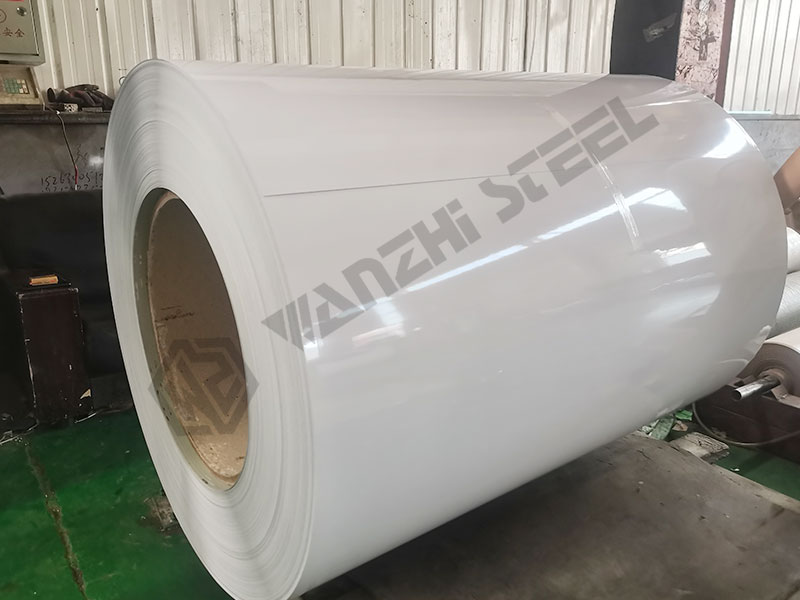

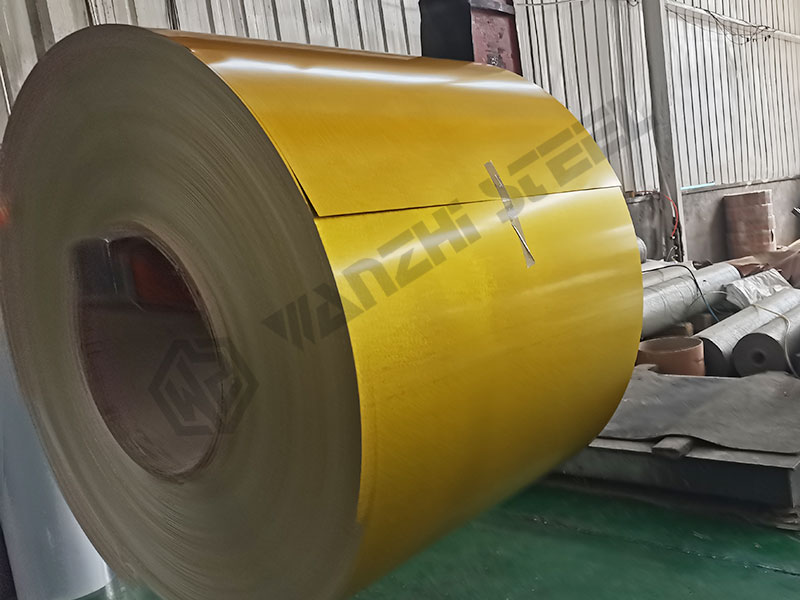

PPGI colors, patterns, and finishes can be customized. For example, matt/wrinkled/glossy PPGI, wooden grain/brick/flowers/PPGI, PPGI blue/black/white/red/gray, etc. PPGI is available in a variety of colors and finishes to meet a wide range of aesthetic needs in a variety of applications such as construction, appliances, and more.

Multi-functional

As a colored metal material, PPGI coil can be bent, stamped, punched, and formed into various shapes of panels, such as roofing panels, home appliance panels, automotive panels, writing panels, and so on.

Easy to install and transport

PPGI steel is characterized by high strength and lightweight, which not only facilitates processing, transportation, and installation but also helps to reduce structural weight.

Long service life

PPGI utilizes functional organic coatings such as PE, SMP, PVDF, HDP, etc., which provide a corrosion resistance of 10-30 years. In addition, organic coatings reduce the environmental impact, making it a more environmentally friendly choice.

Stable performance

PPGI steel remains stable at both high and low temperatures and can be used in various climates, such as high temperature, refrigeration, humidity, salt spray, and other environments.

Customized PPGI Color Coated Steel Coil

Substrate properties, coating quality, specifications, sizes, colors, and patterns determine the performance and application of PPGI steel. As a manufacturer of PPGI steel coil, Wanzhi Group can provide customized solutions according to the application. If you have product drawings and designs, we can also produce them according to your samples.

Wanzhi PPGI Color and Pattern

PPGI Color Ral color cards, or color mixing based on samples. In addition to the color, you can also choose the shade: glossy, matte, and metallic texture.

PPGI pattern: We can manufacture special patterns such as wrinkles, wood grain, floral patterns, camouflage, brick, faux tile, etc. to meet the appearance requirements of different project applications.

Wanzhi PPGI Coated

- Zinc Coating: The customized zinc-coated substrate thickness from 20-350g.

- Paint Coating: top: PE, SMP, HDP, PVDF. Back: epoxy, polyester, acrylic polyhydrogen ester, etc.

- Paint film: top: 10–40 microns, back: 5–20 microns.

Wanzhi PPGI Sizes

We are committed to producing premium PPGI steel that meets international standards, specific specifications and sizes can be customized upon request.

- Material: DX51D, DX52D, DX53D, SGCC, SGCD, Q195, Q235, etc.

- Thickness: 0.12-1.5mm

- Width: 600-1250mm

What is the Price of PPGI Rolls?

One ton of premium PPGI coil price is 600-800 US dollars, PPGI steel price is determined by a variety of factors, billet price, zinc price, paint, varnish, fabrication process, material grade, surface treatment, finished product processing is the key to determine the price of PPGI, through WhatsApp or email to send the product information you need or Pictures, get competitive price from Wanzhi Group!

Where can Buy PPGI Steel Coil?

China, India, Russia, South Korea, Japan, and the United States are the main PPGI-producing countries, if you plan to import PPGI steel products, you can choose PPGI suppliers from these countries.

Supplier – GI GL PPGI PPGL

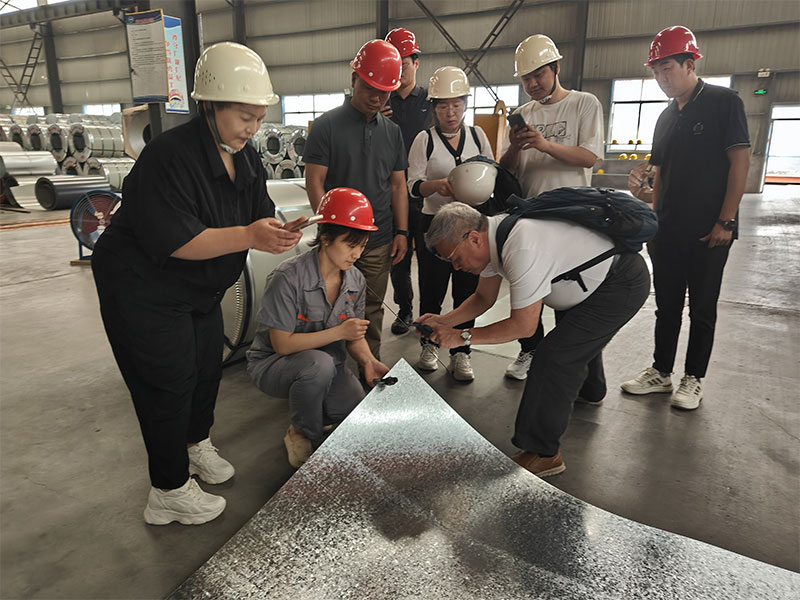

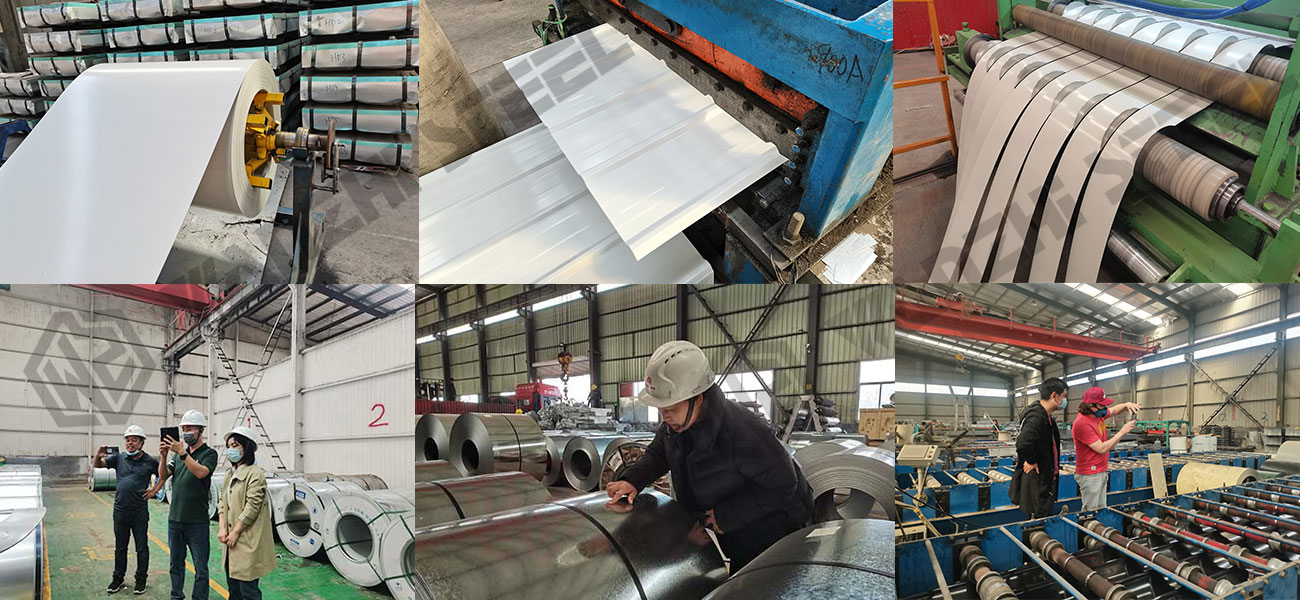

Wanzhi Group is a steel supplier from China, our factory Wanzhi Steel Factory is ISO quality management system certified and has a complete industrial chain from raw material supply to PPGI finished products production, through cost control and quality control to provide customers with competitive prices. Our factory, Wanzhi Steel Factory, has been certified with an ISO quality management system, and has a complete industrial chain from raw material supply to PPGI products production, providing customers with competitive prices through cost control and quality control.

Case

So far, we have provided PPGI steel solutions for construction and industrial applications in more than 100 countries, offering PPGI coil, PPGI sheet, PPGI roofing, etc. at wholesale prices to customers in different fields.

How are PPGI Steel Coils Manufactured?

The structure of the PPGI steel coil consists of a base plate, a galvanized chemical conversion layer, a primer, and a top coat. It is made of hot-dipped galvanized steel coated with an organic coating.

Substrate Preparation

Select cold rolled steel as substrate.

Clean and remove impurities from the steel surface.

Galvanization

For the manufacture of PPGI steel, a hot-dip galvanizing process is usually chosen for the galvanization of the substrate.

Pre-treatment

Galvanized steel requires a surface treatment to enhance the adhesion of the coating.

Painting

The most common methods of painting are roller coating and spraying. The paint is applied evenly to the galvanized steel.

Post-treatment

After galvanizing and painting, the steel is heated at high temperatures to ensure that the coating is bonded to the steel.

Further processing

After curing, the PPGI mounting is cut and rolled. If PPGI panels are to be processed, the PPGI coil can be fed into a molding machine after it has cooled down.

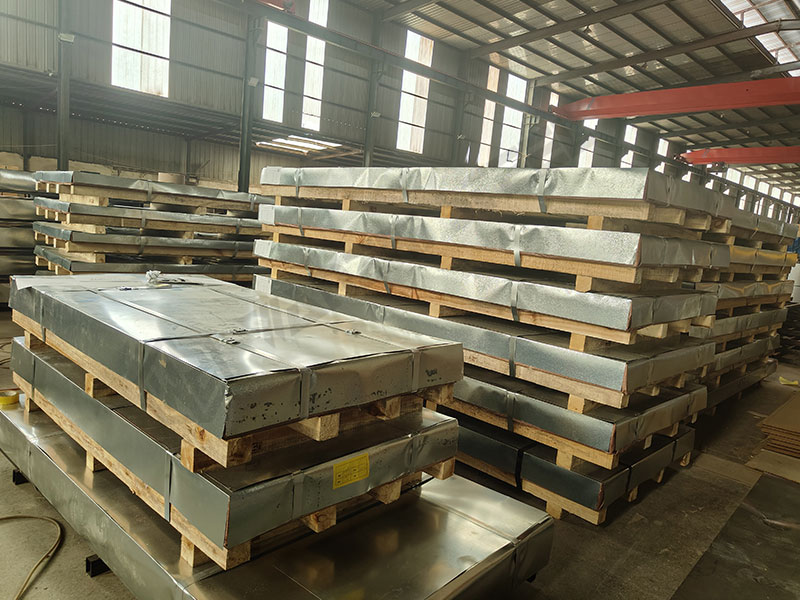

Packaging

Wanzhi’s PPGI coils are packaged according to standard export requirements.

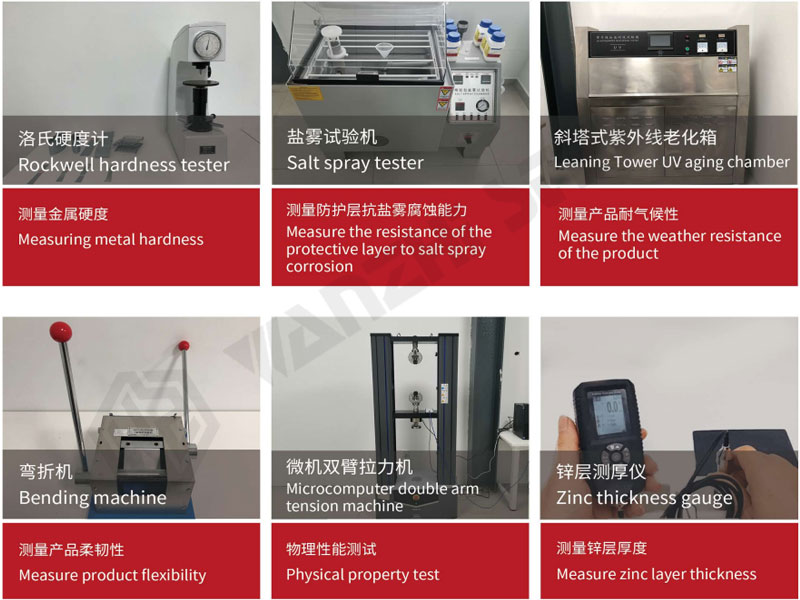

PPGI Steel Coil QA

The finished PPGI steel coil produced by Wanzhi Steel Factory will undergo a series of quality inspections and will be packed and shipped after meeting customers’ requirements. The quality control process includes: a coating uniformity and adhesion check, appearance check, dimensional and tolerance check, physical property test (tensile, bending, impact toughness), chemical property check, etc.

What are PPGI and PPGI Steel Coil?

PPGI steel coil is a kind of color-coated steel, which is also as known as prepainted steel, is hot-dip galvanized steel, electro-galvanized steel, and hot-dip aluminized galvanized steel as the substrate surface coated with organic paint made of colored metal materials. PPGI and PPGL are both made of plated steel coated with organic paint, similar in appearance, and are popular materials for roofing panels, home appliances, automotive manufacturing, and transportation.

Difference between PPGI and PPGI

Substrate

PPGI is based on hot-dip galvanized steel.

PPGL is based on hot-dip galvanized steel.

Physical Properties

PPGI has good strength and toughness and can be bent, molded, and welded.

The strength and toughness of PPGL is similar to that of PPGI.

Chemical Properties

PPGI has good corrosion and weathering resistance.

PPGL has good resistance to corrosion, heat, and weathering, and has better oxidation resistance.

Application

PPGI is used for roofs, walls, ceilings, doors and windows, refrigerators, air conditioners, washing machines, cars, trains, ship and other transportation shell.

PPGL and PPGI have similar applications, but PPGL is more suitable for construction and industrial applications in harsh environments.

Costs

PPGI is low cost, and hot-dip galvanized steel is one of the most cost-effective of the coated steels.

PPGL’s substrate consists of 55% aluminum, 43.4% zinc, and 1.6% silicon, making alloy coatings more cost-effective.

PPGI PPGL Factory – Wanzhi

Wanzhi Group PPGI PPGL factory is located in Binzhou City, Shandong Province, China, we have 2 galvanized production lines, 1 GL ZAM production line, 3 prepared steel production lines, production range: galvanized steel, aluminized zinc plated steel, ZAM steel, PPGI steel, PPGL steel, etc. Production cycle: 5-45 days, MOQ: 10 tons. Customized substrates, coatings, paints, films, finishes, patterns, weights, etc. are available.

If you have any questions about PPGI steel coil or PPGI steel sheet, please feel free to contact us!