| Wanzhi alloy coated | ZAM, ZF, AZ, ZA, ZN, etc. |

| Finished product | coil, sheet, strips, panel, etc. |

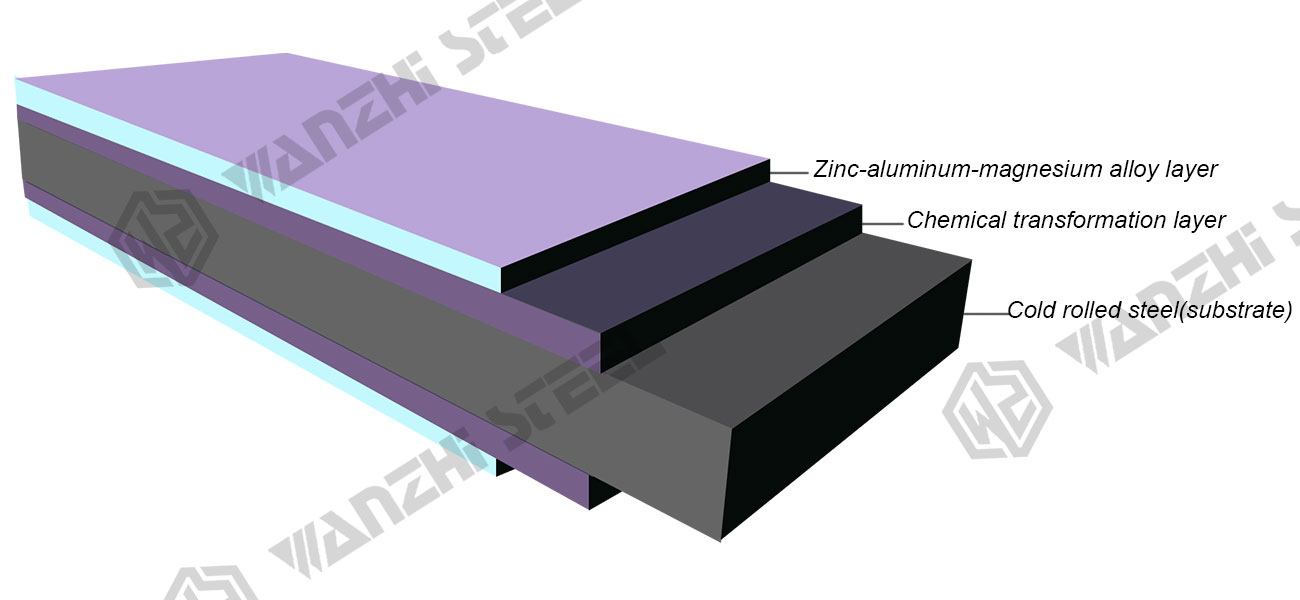

ZAM Material Coating

ZAM Material Coating consists of Zn, Al, Mg, and three other elements, using the hot-dip galvanizing process to mix zinc, aluminum, and magnesium in proportion to the zinc layer of an alloy layer, and then apply to the surface of the steel, to enhance the corrosion resistance of steel, heat resistance, durability, self-healing properties.

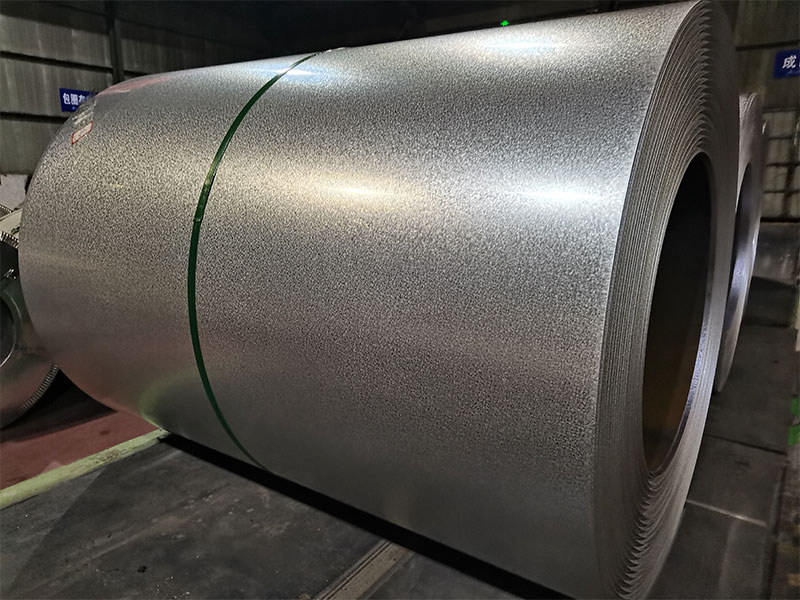

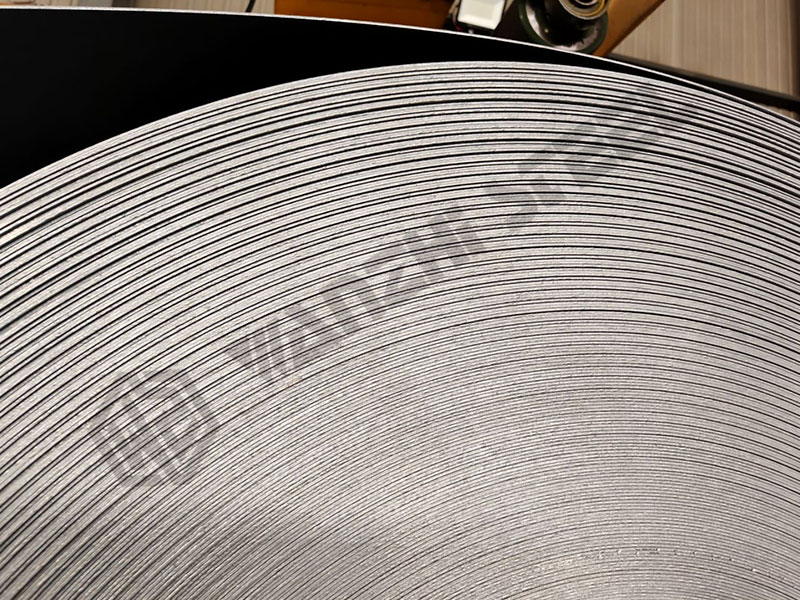

ZAM Steel Coil

ZAM coil material refers to metal coils made from zinc-aluminum-magnesium alloys through a continuous hot-dip aluminum-magnesium plating process. It is usually sold in coils, with a weight of 3–5 tons per coil (customizable).

Usage of ZAM coils: Mainly used as raw material for large-size production, deep processing, and molding.

ZAM coils weight calculation: Width (m) × Length (m) × Thickness (mm) × Density (kg/m³).

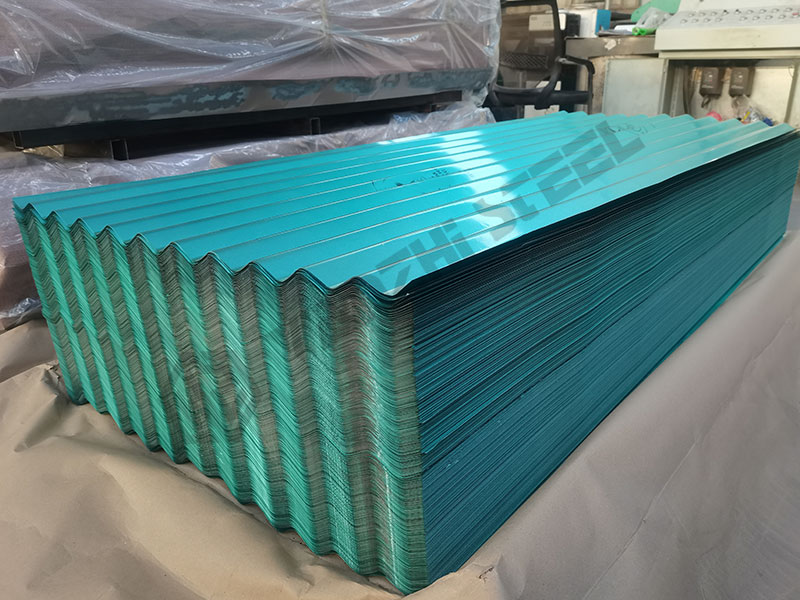

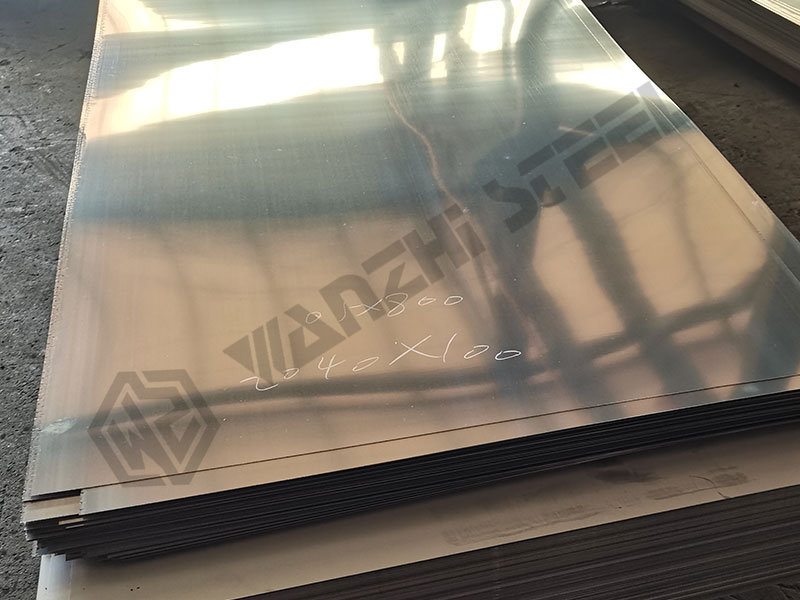

ZAM Steel Sheet

ZAM steel sheet is a sheet of metal that is cut and processed after the ternary alloy layer has been applied to the surface of steel by the hot-dip aluminum-magnesium plating process and is usually sold and shipped in the form of flat sheets.

ZAM sheets used for: Direct use or small-scale production requiring flat sheets for cutting and forming materials.

ZAM sheets Weight: Length (m) × Width (m) × Thickness (mm) × Density (kg/m³).

ZAM Material Benefit

- Corrosion resistance: Protected by three metal elements, zinc, aluminum, and magnesium, ZAM steel has excellent corrosion resistance and can be used as a substitute for stainless steel in some areas.

- Wear resistance: The addition of aluminum and magnesium improves the wear resistance of the alloy coating.

- Self-healing: The sacrificial anode effect of zinc in ZAM coating can protect the metal material, while aluminum and magnesium can enhance self-healing.

- Machinability: ZAM steel inherits the ductility, plasticity, and weldability of steel, and can be bent, cut, and formed.

- Aesthetics: Alloy-coated steel, the surface has a metallic luster.

- Fire resistance: ZAM coating will form an oxidized layer under high temperatures to reduce the risk of fire, ZAM color-coated steel can reach an A1 class fire rating.

ZAM Material Application

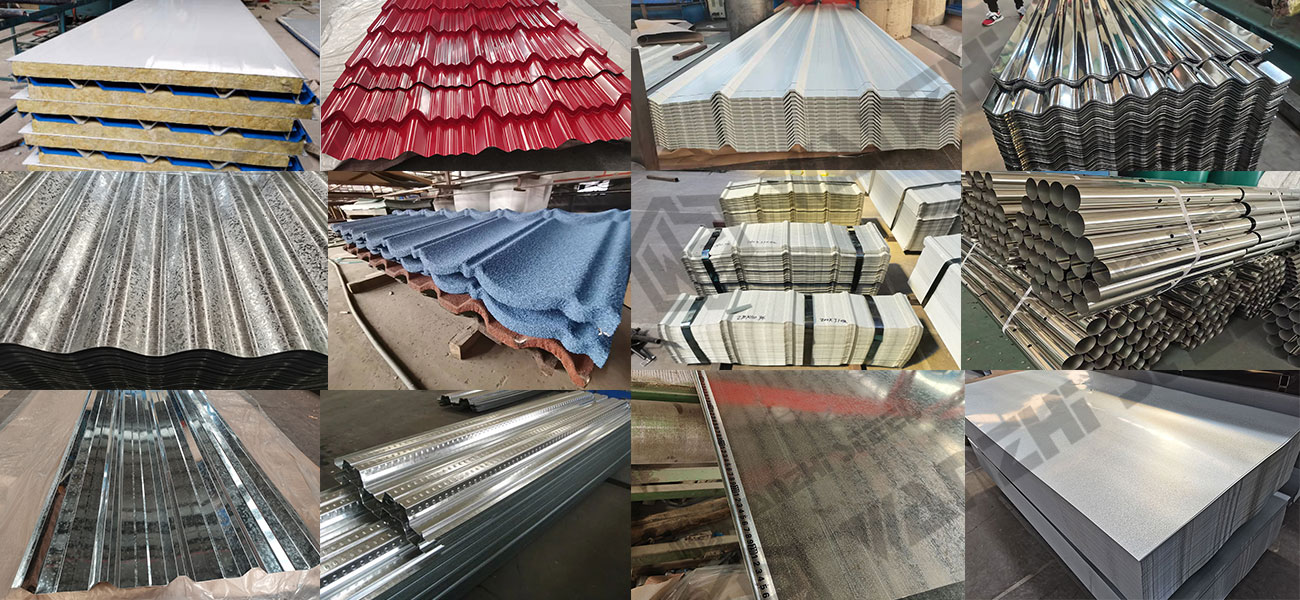

ZAM material is widely used in harsh environments such as marine environments, humid and high-temperature environments, industrially polluted environments, outdoor construction, and agriculture. Applications for ZAM steel coil and sheet include: building cladding, building structures, infrastructure such as roads and bridges, ship hulls, railroad tracks, aircraft and automobile exteriors and components, oil pipelines, natural gas pipelines, cooling towers, wind turbines, solar racks and panels, power towers, transformers and more.

ZAM Steel Coil and Sheets Supplier

ZAM steel factory and supplier – Wanzhi Group, So far, we have supplied ZAM materials to many countries in Central Asia, Southeast Asia, Africa, etc. As a professional ZAM steel supplier, dedicated to premium coated steel (metal-coated steel, alloy-coated steel, and color-coated steel.) by international standards, we have provided cost-effective solutions for applications in different fields (automotive, energy, construction, power, etc.), as well as premium ZAM coils and sheets.

ZAM Production

As a professional coated steel manufacturer, Wanzhi Factory has 1 ZAM production line, which has obtained ISO quality management system certification, CE certificate, and SGS certificate, and we use precise coating technology and precise slitting and cutting equipment, in addition to hot-dip aluminum-magnesium plating, electroplating aluminum-magnesium plating, spraying can also provide bending, stamping, slitting, forming, and other in-depth processing.

ZAM Steel Customization

We offer customized ZAM steel coil, ZAM steel sheets, and ZAM panels according to your project needs and applications, customized in terms of: zinc-aluminum-magnesium ratio, steel material grade, alloy layer thickness, ZAM steel specifications, surface treatment, color, pattern, weight, packaging, etc.

Supply Chain Management

We are always flexible in supply chain management to meet the requirements of different industries for a timely and stable supply of ZAM material. In addition, Wanzhi Factory can flexibly adjust the production according to the order quantity and demand, to provide production efficiency and reduce the production cost to provide the more competitive price of ZAM.

Price of ZAM material – Wanzhi Group

ZAM steel is a highly corrosion-resistant metal material, combining the advantages of steel and zinc, aluminum and magnesium, it is more costly than traditional metal materials and metal coating materials, so ZAM steel is more expensive, leave us a message to tell you what specifications of ZAM material you need, and let us provide you with a competitive price!

Hot Metal Material

ZAM Material is a new type of alloy metal material, which is widely used in construction, industry, and other fields because of its excellent performance. If you are looking for a ZAM supplier or factory, then don’t hesitate to contact Wanzhi Group!