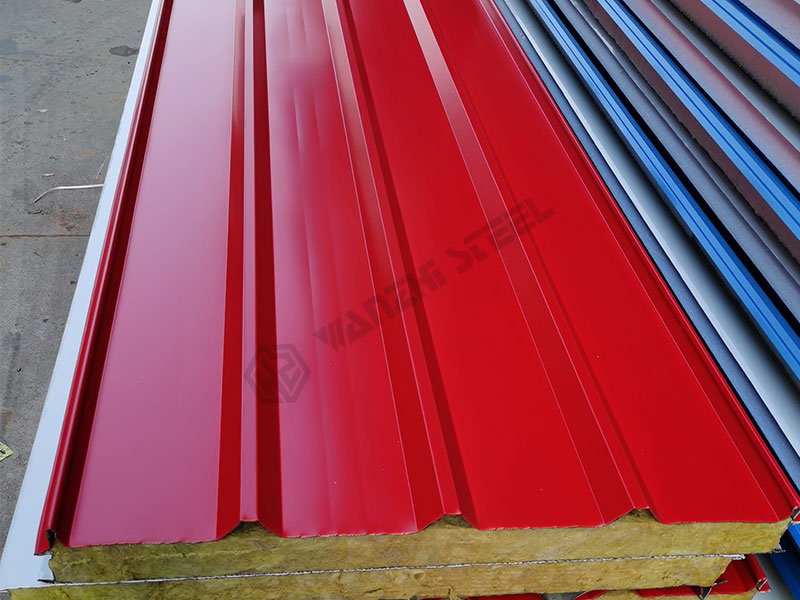

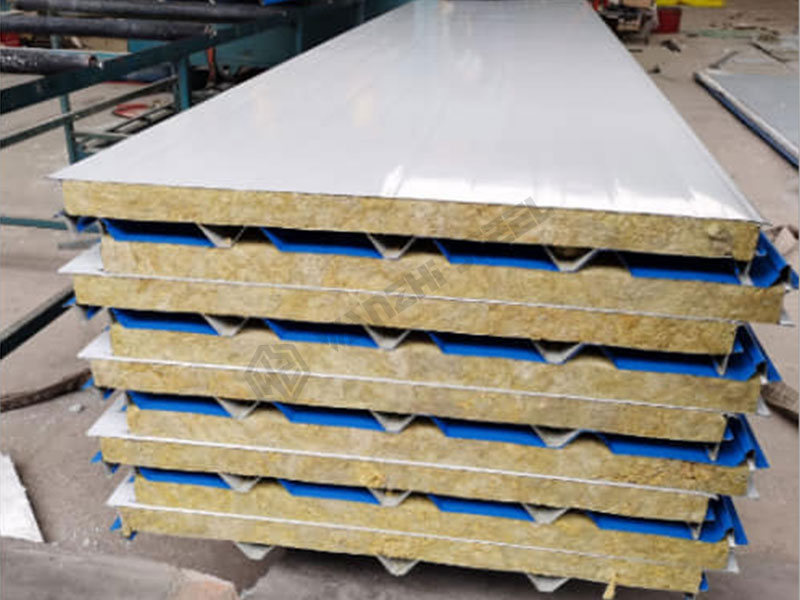

Metal sandwich panels are structural composites made of a combination of materials with different properties, usually consisting of two layers of metal sheets (outer and inner) plus a layer of sandwich material. The metal sheets (galvanized steel, color-coated steel, stainless steel, etc.) achieve corrosion resistance, while the sandwich layer provides acoustic, thermal, and heat preservation. The sandwich layer provides sound insulation, thermal insulation, and heat preservation. It is a commonly used roofing and walling material.

What are the Categories of Metal Sandwich Panels? (Core Material)

According to the sandwich material of the sandwich panel, can be divided into PU, Rockwool, EPS, PF, Aluminum honeycomb, PE, Glass wool sandwich panel, among which the cost-effective and popular ones are PU and Cotton Rock sandwich panel.

The Role of Different Core Materials

- PU: Polyurethane foam sandwich panels are unsuitable for wet environments, but their thermal insulation and fire-resistant effects are excellent.

- Rockwool: Rockwool sandwich panels are heavy, but have good fire resistance, and thermal and acoustic insulation.

- EPS: Expanded polystyrene sandwich panels have poor fire resistance, but are low cost.

- PF: Phenolic panels are expensive, but have excellent fire resistance.

- Aluminum honeycomb: Aluminum honeycomb panels are costly, strong, and lightweight, and provide both thermal and acoustic insulation.

- PE: Polyethylene foam sandwich panels with low cost, general insulation, and fireproof effect.

- Glass wool: glass wool sandwich panels have good thermal and acoustic insulation effects, but the environmental requirements are high.

Which One is Better?

Sandwich panels are mainly used for aesthetics, sound insulation, thermal insulation, fireproofing, and thermal insulation, you can choose a cost-effective panel material according to the project needs to install a variety of core materials functions.

- You can choose a PU sandwich panel for the panels that need a thermal insulation effect. (For example, cold storage, refrigerated truck, etc.)

- If you need a good fireproof effect, you can choose rock wool or PF sandwich panel. (For example, the walls and roofs of industrial plants and public buildings, etc.)

- Small budgets can choose an EPS sandwich panel.

- For those who have very high requirements on strength and material, you can choose an aluminum honeycomb sandwich panel. (Airports, ships, etc.)

What are the Panels of Metal Sandwich Panels? (Exterior Material)

Sandwich panels consist of a metal panel and a core material. In addition to the core material, the sandwich panels can be classified according to the material of the metal panel as galvanized steel, aluminum alloy, stainless steel, pre-coated steel, aluminum zinc-plated steel, colored aluminum, or aluminum-magnesium-manganese alloy sandwich panels.

Functions of the Different Panel Materials

- Galvanized steel: Steel with a layer of zinc on the surface, the main purpose is to resist corrosion, the cost of this steel is low, and easy to process and form.

- Aluminum alloy: Aluminum has high heat reflection and low density, so aluminum alloy panels are corrosion-resistant, heat-resistant, and lightweight.

- Stainless steel: excellent corrosion and oxidation resistance, high-temperature resistance, easy to clean but costly to process.

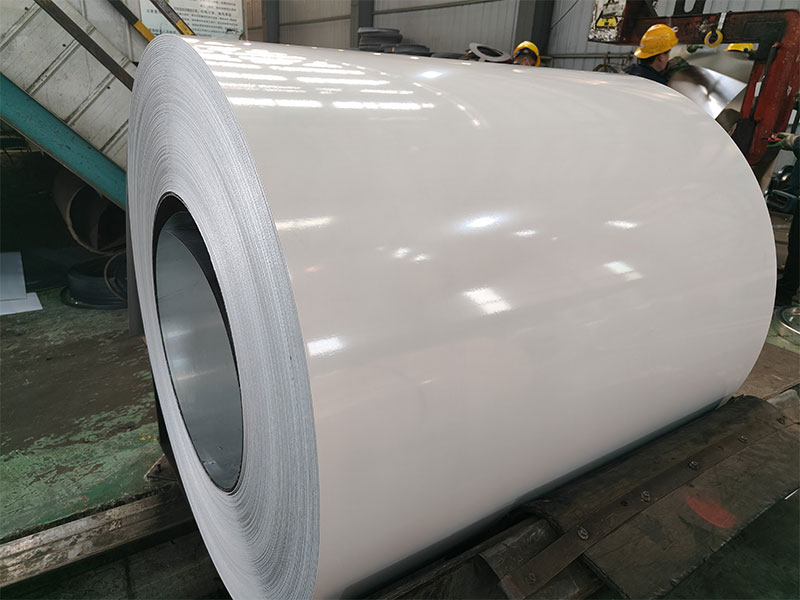

- Pre-coated steel: Pre-coated galvanized steel (PPGI steel) and pre-coated galvalume steel(PPGL steel), are corrosion resistant, a good decorative effect.

- Galvalume steel: Similarly, heat reflective and corrosion resistant, higher cost than galvanized steel, and lower cost than aluminum alloys.

- Colored aluminum: colorful, weather resistant, corrosion resistant, and decorative, higher cost than pre-coated steel.

Which Panel is Better?

- For roofs and walls of buildings in general outdoor environments, you can choose galvanized steel sandwich panels.

- For roofs and walls of high-grade commercial buildings, aluminum sandwich panels are preferred.

- Roofs and walls of buildings in seaside, industrial areas, and chemical plants can be made of stainless steel or zinc-aluminum sandwich panels.

- Residential and commercial buildings with high demand for appearance can choose prepainted steel and colored aluminum sandwich panels.

Advantages and Applications of Metal Sandwich Panels

Metal sandwich panels combine the advantages of a variety of materials to enhance the physical properties of the panels, such as strength, stiffness, and toughness, while the different materials of the core material also bring special features.

Benefits

- Thermal insulation

- Thermal insulation

- Soundproofing

- Wind pressure resistance

- Durability

- Corrosion resistance

- Easy to install

Application

- Residential and commercial building exterior walls, roofs, ceilings, partitions, etc.

- Cold rooms, refrigerated truck compartments, etc.

- Industrial plants

- Food processing plants

- Dust free laboratories

- Acoustic walls

Metal Sandwich Panel Factory and Production Line

Wanzhi Group is an ISO-certified Chinese steel manufacturer specializing in the production and sale of coated steel, has a sandwich panel production line and metal panel production line for various materials, we can design and produce various specifications of grades of metal materials and sandwich panels according to the project requirements, has a wide range of products to meet the needs of our customers.

Whether you are looking to purchase steel coils, steel sheets for sandwich panels, or just normal sandwich panels for your project, you will get the products you need from Wanzhi Group! Contact us for a quote or sample!