Today we’ll address a common question from many customers: “Why is PPGI steel often cheaper than GI steel in the quotes I receive?” Is it normal for galvanized steel (GI) to cost more than pre-painted galvanized steel (PPGI), which has already undergone color coating?

What are GI and PPGI?

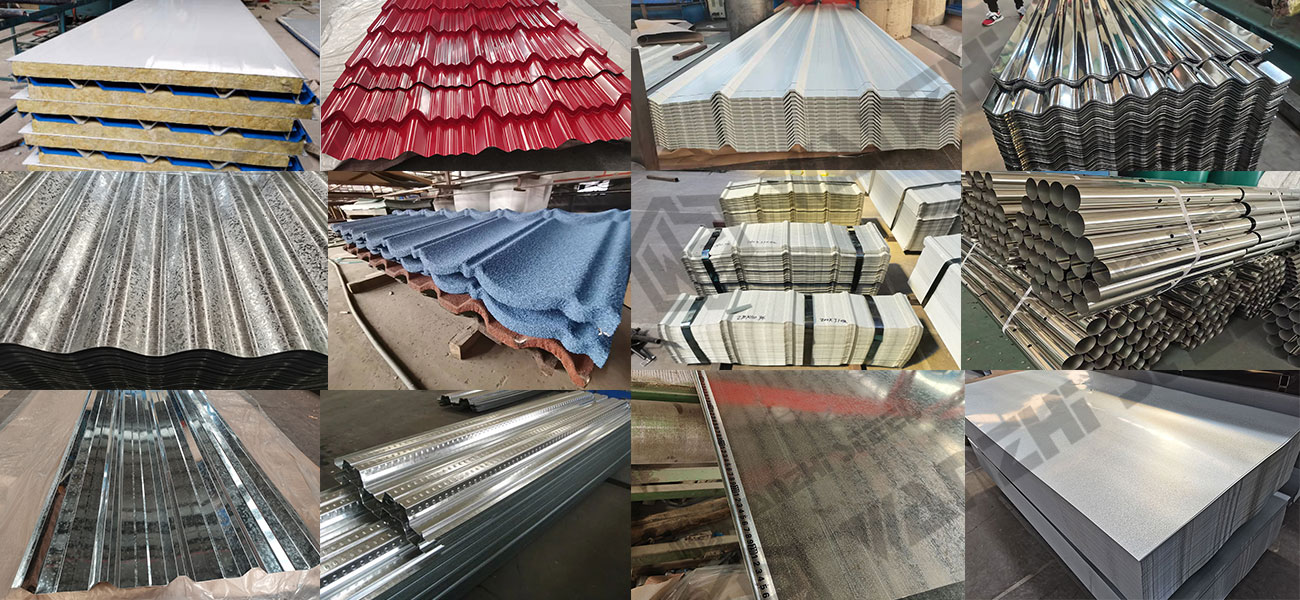

GI: Full name: Galvanized Steel. This is a pure zinc-coated steel produced by electrogalvanizing or hot-dip galvanizing cold-rolled steel as the substrate. It is one of the most common corrosion-resistant metal materials. Its corrosion resistance lifespan is determined by the thickness of the surface coating. Currently, Wanzhi Group’s GI steel coating thickness ranges from 30-600g/㎡.

PPGI: Full name is pre-painted galvanized steel. Its core is a colored coated steel formed by galvanizing and painting the surface of a cold-rolled substrate. Beyond corrosion resistance, it offers decorative and other additional functions. Besides coating thickness, the paint material of PPGI steel also plays a crucial role. Currently, Wanzhi Steel’s popular paint materials include PE, HDP, PVDF, etc.

Production Processes for GI and PPGI

The notion that “more processes mean higher costs” does not hold true when comparing GI and PPGI. Firstly, their core production processes are highly similar. Secondly, the additional process costs for PPGI are far lower than the cost difference stemming from raw material variations. Furthermore, numerous PPGI production lines exist, leading to intense market competition and consequently influencing pricing.

Common Production Processes for GI and PPGI

- Uncoiling and Leveling: Cold-rolled steel coils are uncoiled and leveled to ensure flatness.

- Alkali Washing and Degreasing: Alkaline cleaning removes surface contaminants like oil and dust.

- Acid Pickling and Rust Removal: Eliminates surface oxide layers to achieve a clean, reactive surface;

- Chemical Passivation: Applies a passivating agent to form a thin protective film, enhancing adhesion between the steel and subsequent zinc/paint coatings while improving corrosion resistance.

Differentiated Production Processes for GI and PPGI

- GI Production Process: After pretreatment, steel sheets are directly immersed in a molten zinc bath (approx. 450°C) for hot-dip galvanizing. Zinc adheres to the steel surface, solidifying upon cooling to form a protective zinc coating. The sheet then undergoes trimming, coiling, and other processes to produce finished GI products. The galvanizing process consumes significant energy, with zinc consumption being the primary cost driver. Coating thickness (e.g., Z30, Z60, Z80, Z120, Z180, Z275) directly determines the cost.

- PPGI Production Process: PPGI utilizes GI substrate with a relatively thinner coating, followed by two critical coating steps: First, an epoxy primer is applied; then a topcoat is applied; finally, the material enters a curing oven for high-temperature curing to ensure the paint coated adheres firmly to the zinc coating. Although equipment and energy consumption are required, the material cost of the paint itself accounts for a relatively low proportion, and the coating speed is extremely fast, resulting in high production efficiency.

GI and PPGI Raw Materials

GI steel consists of a substrate + coating; PPGI steel consists of a substrate + coating + paint coating. The core coating material for GI is zinc, while PPGI’s core coating material is paint. When you find PPGI cheaper than GI, it’s typically because you’re comparing “GI steel with standard zinc coating thickness” to “PPGI steel with a thin-zinc substrate.” Since paint costs significantly less than zinc, the substantial difference in unit price and material usage between these two materials directly accounts for their price disparity.

The price difference between GI steel and PPGI steel is determined by the thickness and material of their core coatings. Occasionally, GI steel may be priced higher than PPGI, which is entirely normal. If you have further questions about selecting GI or PPGI materials or their pricing, feel free to contact us anytime. Wanzhi will provide one-on-one customized solutions tailored to your specific requirements!