VCM vs. PCM

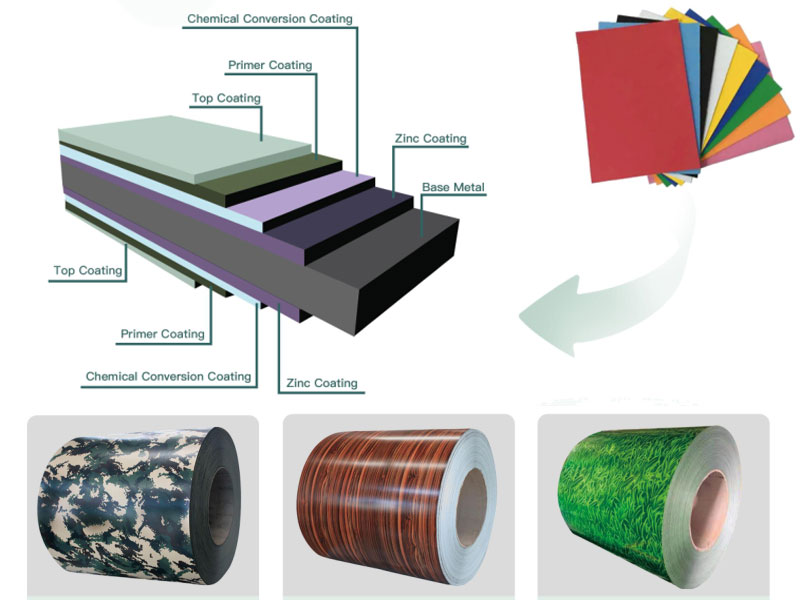

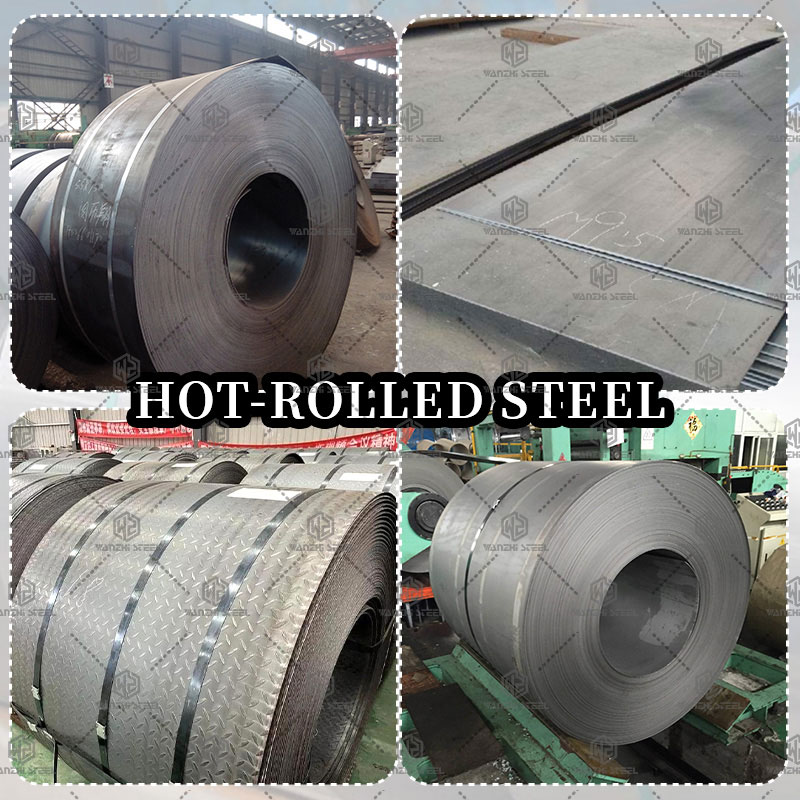

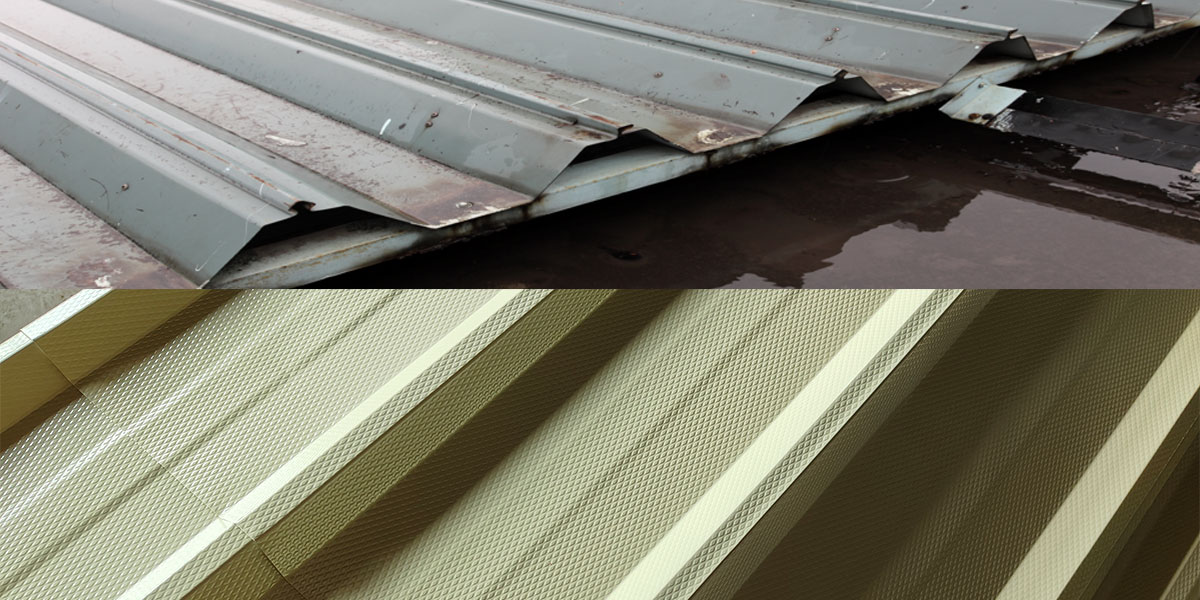

VCM stands for Vinyl Clad Metal or Vinyl Laminated Metal, referring to vinyl-coated metal panels. PCM stands for Pre-Coated Metal, referring to pre-coated steel sheets. VCM and PCM are two common metal surface treatment methods. PCM has lower processing costs and is widely applied. VCM is a more advanced surface treatment technology developed from PCM, […]