Zinc coated steel is a pure zinc coated metal material, which is the ideal corrosion protection material balancing cost, performance and environmental friendliness. Wanzhi Gruop can provide cost-effective solutions according to the corrosion level of the environment (e.g., coastal, industrial areas), processing needs (stamping, welding, bending), and life expectancy (short-term protection vs. long-term maintenance-free).

Zinc Coated Steel Information

Zinc-coated steel, also called Galvanized steel/GI steel, is one of the most common anti-corrosion steel, through hot-dip or electro-galvanized zinc plating to form a layer of zinc to protect the substrate by isolating the steel from direct contact with moisture and oxygen, with a zinc content of Zn ≥ 99%, the cost of the lowest, the process is mature, and the resistance to salt spray test in 500-1500 hours.

Structure

| Layer | Composition and Function |

|---|---|

| Base Steel | – Low carbon steel or high-strength steel. |

| Zinc Coating | – Pure zinc layer or zinc alloy layer (e.g., Zn-Fe, Zn-Al).

– Sacrificial anode protection + physical barrier. |

| Passivation Layer | – Chromate/non-chromate passivation film (e.g., zirconium-based, titanium-based). |

| Organic Coating (Optional) | – Epoxy, polyester, or fluorocarbon coatings (e.g., color-coated sheet PPGI). |

Processes

Hot-Dip Galvanizing (HDG)

- Process: Steel is immersed in molten zinc (450~465℃) → formation of zinc-iron alloy layer → pure zinc layer on the surface.

- Characteristics: thick coating, rough surface, zinc flowers, strong corrosion resistance (salt spray life of 20 ~ 50 years)

- Standard: ASTM A123, ASTM A653.

Electrogalvanizing (EG)

- Process: Deposition of zinc layer by electrolysis at room temperature → passivation (e.g. chromate) → drying.

- Characteristics: Thin coating, smooth surface without zinc bloom.

- Standard: ASTM B633.

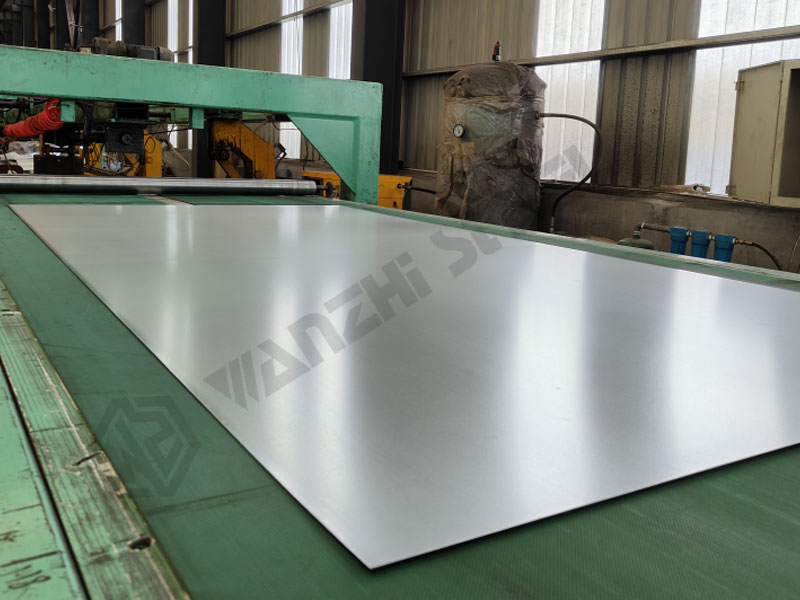

Zinc Coated Steel for Sale

Wanzhi Group is selling a wide range of zinc coated steel (GI steel) at wholesale prices. We provide coated steel materials for architectural, industrial and other applications in accordance with international standards such as ASTM A123, ASTM A653, ASTM B633, EN 10346, JIS G3302, ISO and others.

Specification

We offer a wide range of services such as production to specified dimensions and design and production to suit the application.

| Property | Description |

|---|---|

| Thickness | 0.15-6mm (Common: 0.2/0.3/0.4/0.5/0.6/0.8/1.0/1.2/1.5/2.0/2.5/3.0) |

| Width | 1000mm/1200mm/1250mm |

| Galvanizing Method | Hot dip galvanizing, electro galvanizing |

| Zinc Layer Thickness | 40-150μm, Z/AZ20-Z/AZ350 (1μm≈7.05g/m²≈0.001oz/ft²) |

| Substrate Type | Q195-Q345/SGCC/American Standard G30, G60, G90/SGCC, SGCD1, SGCD2, SGCD3, SGC340, SGC400, SGC440/European Standard DX51D, DX52D, DX53D, DX54D |

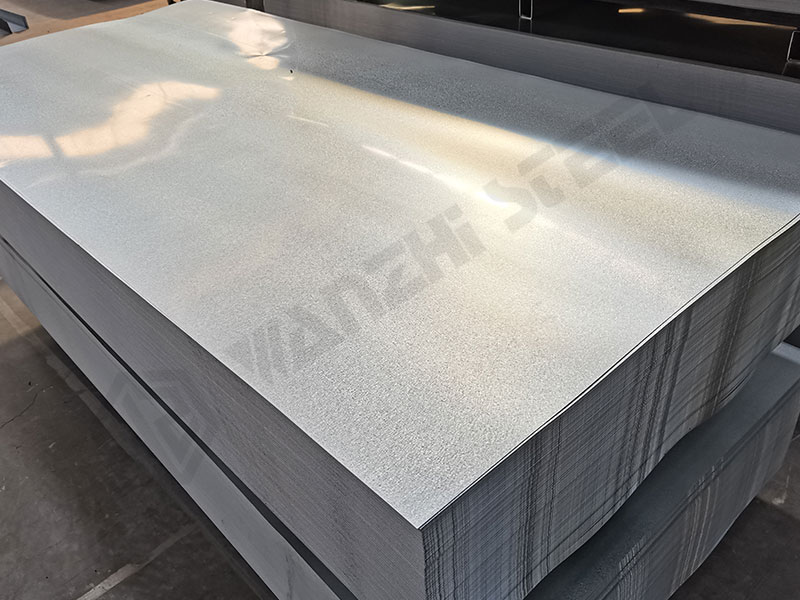

| Surface Treatment | Passivation/oil coating/lacquer sealing fingerprint resistance/phosphatization |

| Surface Zinc Bleaching | Normal/Slight/Spotted |

| Unit Weight | 8-10t |

| Packing | Standard export packing (plastic film + moisture-proof paper + galvanized iron) |

Zinc Coated Steel Price

The price of zinc coated steel is 600-800USD per ton, which is determined by the thickness of zinc coating, specification and material grade. We can customize zinc coated steel materials and finished products with special specifications, surfaces and shapes, of course, the special specifications are different from the regular specifications in terms of price and delivery time. If you are looking for galvanized steel OEM/ODM, then contact us for solution and price list!

Zinc Coated Steel Features

Zinc coated steel meets a wide range of requirements such as extreme corrosion resistance, precision appearance, light weight + low cost, complex shapes, and environmental protection.

Benefits

- Long-lasting protection: zinc coating as a sacrificial anode + physical barrier for extreme environments.

- Easy processing: stamping, bending, deep drawing, welding, painting, printing or laminating.

- Economical: Low processing costs, low maintenance costs.

- Wide range of applications: Wide range of applications in construction, automotive, home appliances, agriculture, etc.

Usages

Construction and infrastructure: steel roofs, bridge guardrails, transmission towers, fences.

- Recommended process: hot dip galvanizing (Z80-275 galvanization, salt spray life ≥ 50 years).

Automotive industry: body panels, chassis parts, fuel tanks.

- Recommended process: electro-galvanizing + painting.

Home appliance manufacturing: washing machine inner tube, refrigerator shell, air conditioner bracket.

- Recommended process: hot dip galvanizing (Z20~Z120) + pre-painting (PE/PVDF/SMP/HDP).

Agriculture and Marine: greenhouse skeleton, fishing boat parts, dock facilities.

- Recommended process: hot dip galvanizing (Z180~Z275) + thick coating (≥20μm).

Comparison of Zinc Coated Steel and Other Coated Steels

Currently, Wanzhi Group’s hot-selling coated steels include: galvanized coated steel, aluminum-zinc alloy coated steel, zinc-aluminum-magnesium coated steel, and organic coated steel, which comply with ASTM A653 (American Standard), EN 10346 (European Standard), ASTM A792 (American Standard), JIS G3321 (Japanese Standard), ASTM A792 (American Standard), JIS G3321 (Japanese Standard), ASTM A755 (Coating Properties), GBT 12754 (Chinese Standard), and other international standards. In addition, we also provide deep processing services such as stamping, slitting, molding, cutting, punching, etc. for coated steel.

| Coating Type | Main Composition | Corrosion Protection Mechanism | Corrosion Resistance (Salt Spray Test) | Typical Applications |

|---|---|---|---|---|

| Galvanized Steel | Pure Zinc (Zn ≥ 99%) | Sacrificial Anode + Physical Barrier | 500~1500 hours | Building structures, common pipes, fences |

| Aluminum-Zinc Alloy Coated Steel | 55% Al – 43.4% Zn – 1.6% Si | Aluminum Passivation + Zinc Sacrificial Protection | 1500~3000 hours | Roofs, car exhaust pipes, high-temperature equipment |

| Zinc-Aluminum-Magnesium Coated Steel | Zn – 6% Al – 3% Mg (ZAM) | Magnesium Enhanced Self-Healing + Multi-layer Passivation Film | 3000~6000 hours | Marine engineering, agricultural machinery, car chassis |

| Organic Coated Steel (Pre-painted Steel) | Zinc layer + Epoxy/Polyester/Fluorocarbon coating | Physical Isolation + Chemical Stability | 1000~5000 hours (depending on coating) | Building facades, appliance panels, billboards |

| Tin Coated Steel | Pure Tin (Sn ≥ 99%) | Inert Barrier (Food-grade corrosion protection) | 200~500 hours | Food cans, electronic components, decorative parts |

Zinc Coated Steel Factory and Manufacturer

Wanzhi Group is a zinc coated steel factory supplier from China, our factory Shandong wanzhi steel is ISO4001, ISO14001 certified, we can produce galvanized steel, aluminum zinc plated steel, zinc aluminum magnesium plated steel, paint coated steel, corrugated steel, tubes, strips, etc. We also provide one-stop service to supply carbon steel, wire mesh, stainless steel, aluminum alloy and other metal materials for construction and industrial use as well as finished products. We also offer a one-stop service for the supply of carbon steel, wire mesh, stainless steel, aluminum, etc., as well as finished products for construction and industrial use.

Production Capacity

Wanzhi steel factory consists of 2 zinc coated lines, 1 alloy coated line, 3 painted steel lines, 1 writing board line, as well as several precision slitting lines, corrugated board processing lines, etc.

Supply Capacity

Annual production capacity of 600,000 tons, fastest delivery time from stock is 5 days, customized delivery time is up to 45 days, we can provide samples of coated steel in various specifications and styles.

One-Stop Service

Wanzhi Group as a factory supplier is able to meet the needs of different customers by providing comprehensive services such as product design, raw material sourcing, customized production, special request customization, mass production, machining services, quality inspection, performance testing, warehouse management, repair and maintenance, and so on.

Customer Feedback

Until now, our coated steel materials and finished products have been exported to more than 100 countries and regions, bringing cost-effective solutions for factories, construction projects, traders and other customers with different application needs.

What value do you need zinc coated steel to bring to your project? Leave us a message to discuss the most cost-effective coated steel solution for your project!