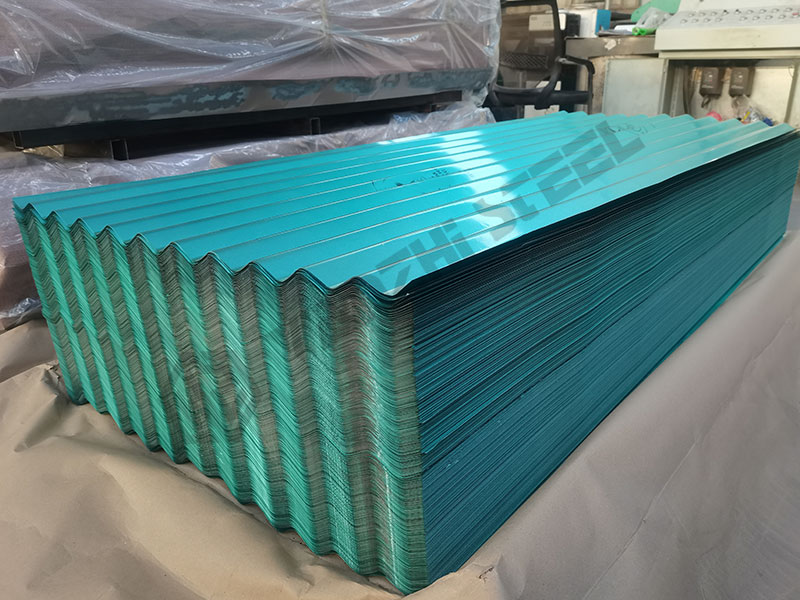

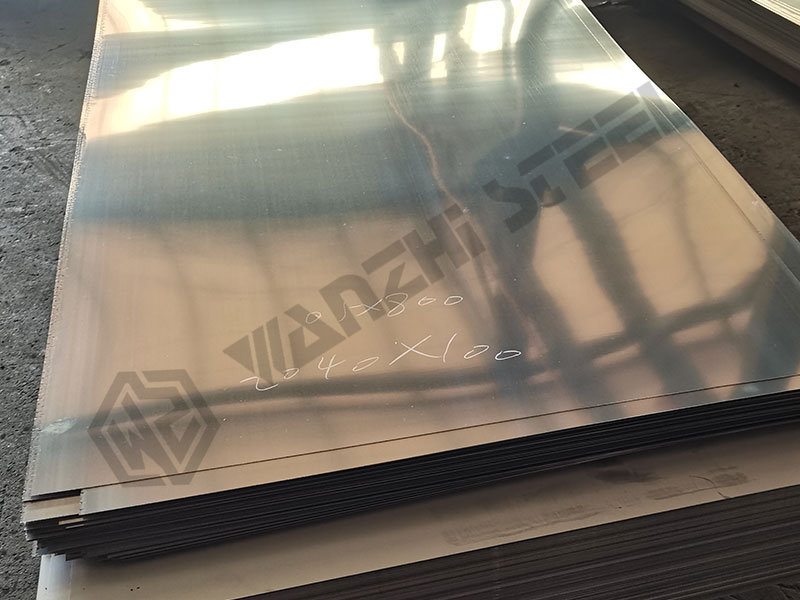

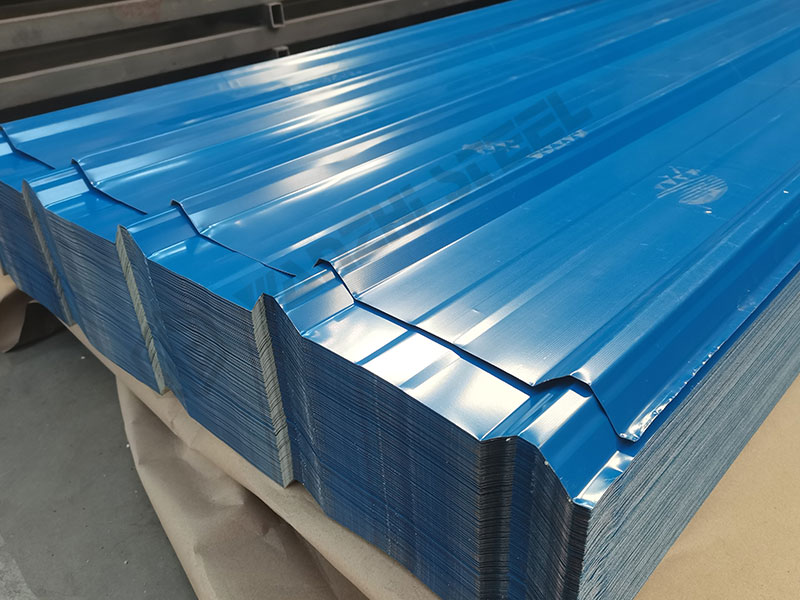

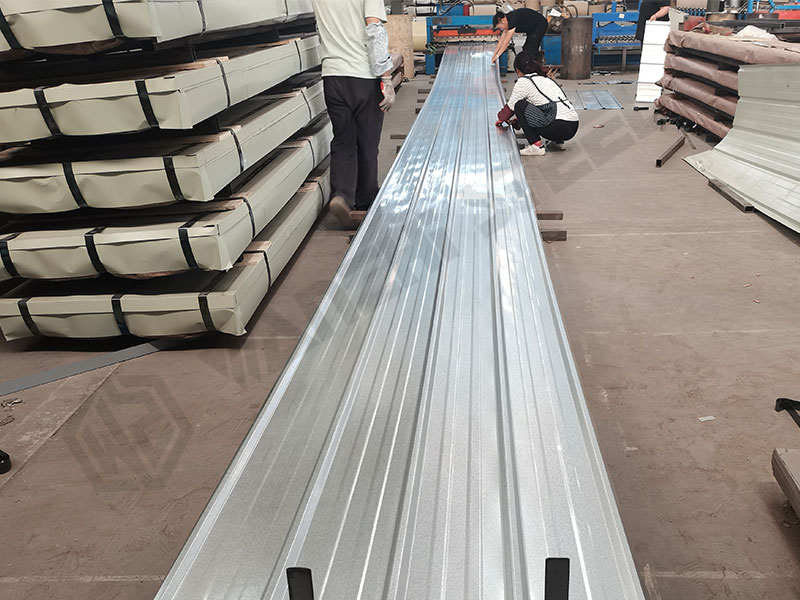

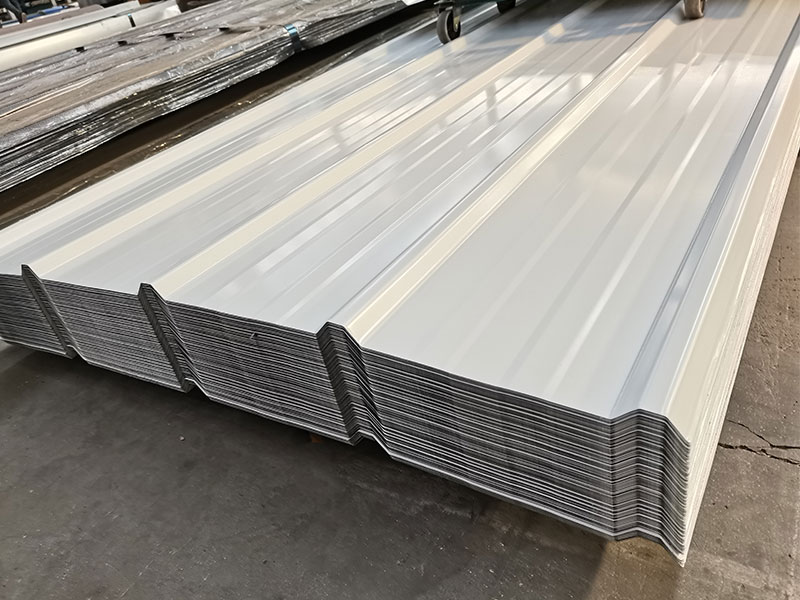

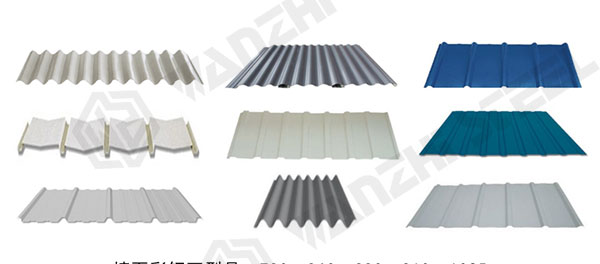

Color-coated steel sheets (PPGI sheets, PPGL sheets) are popular building materials that play a vital role in architectural walls, roofs, ceilings, partitions, and floor decking structures through various forms such as flat sheets, corrugated sheets, and profiled sheets. The thickness of color-coated steel sheets determines their durability, corrosion resistance, tensile/compressive strength, snow load capacity, and impact resistance, directly influencing the service life of construction projects.

Select Based on Application Scenarios

| Application Scenario | Recommended Thickness (mm) | Key Factors |

| Building Exterior Wall | 0.5~0.8 | Wind resistance, weatherability, decorative aesthetics |

| Roof | 0.6~1.0 | Drainage slope, snow load resistance, structural strength |

| Interior Partition | 0.3~0.5 | Lightweight design, ease of installation, fire resistance, visual appeal |

| Sandwich Panel (Face Sheet) | 0.4~0.6 | Weatherability, fire resistance, cost-effectiveness |

| Floor Deck (Profiled Steel) | 0.8~1.2 | Structural support |

| Home Appliance Housing | 0.4~0.6 | Aesthetic finish, moldability, scratch-resistant coating |

| Industrial Equipment Enclosure | 0.8~1.2 | Impact resistance, corrosion protection |

| Transportation Vehicles | 0.6~1.0 | Balance of lightweight design and strength |

Select Based on Purlin Spacing

| Purlin Spacing | Roof Panel Thickness | Wall Panel Thickness |

| ≤ 1.0 meter | 0.5 mm – 0.6 mm | 0.4 mm – 0.5 mm |

| 1.0 meter – 1.5 meters | 0.6 mm – 0.8 mm | 0.5 mm – 0.6 mm |

| ≥ 1.5 meters | ≥ 0.8 mm | ≥ 0.6 mm |

Influencing Factors

Application

Roofs must withstand wind loads, rain and snow loads, as well as foot traffic from construction and maintenance personnel, thus typically requiring greater thickness than walls.

- Roofs: Recommended thickness of 0.5mm to 1.2mm to ensure resistance to wind pressure, snow loads, and deformation capacity.

- Walls: 0.3mm to 0.5mm thickness may be selected to balance cost and performance.

- Special Conditions (e.g., high corrosion environments, mechanical impact zones): Require thickness ≥0.8mm with high weather-resistant coating.

Supporting Purlin Spacing

Wider purlin spacing allows greater panel spans but demands higher panel strength, stiffness, and increased thickness.

Note: Each increment in purlin spacing may require upgrading the panel thickness grade.

Processing

Punching/Bending: Thin sheets (≤0.5mm) are prone to deformation; allow processing allowance or select products with flexible pre-coated finishes.

Welding/Riveting: Thick sheets (≥1.0mm) require assessment of coating damage from welding; apply post-coating processes when necessary.

Corrosive Environments

Standard environments (inland, urban): Standard thickness sufficient, ≥0.6mm.

Harsh Environments (Industrial Zones, Coastal Areas, High Humidity): Recommend sheets ≥0.6mm and more corrosion-resistant coatings (e.g., high-zinc coatings, PVDF topcoats).

Wind and Snow Loads: Determine minimum thickness via structural calculations based on geographical location and climate conditions. Coastal typhoon zones and northern heavy snow regions require increased thickness.

Design Lifespan

Short-term use (within 10 years): 0.45mm–0.6mm, with standard polyester (PE) coating

Medium-term use (10–20 years): 0.6mm–0.8mm, with high-weathering polyester (HDP) coating

Long-term use (20+ years): ≥0.8mm, PVDF fluorocarbon coating

Cost Budget

Panel thickness constitutes the primary cost component. Selecting an economically viable thickness while meeting safety and functional requirements is critical. Each 0.1mm increase in thickness raises costs by approximately 5%–10%, necessitating optimization based on project budgets.

Premium Color-Coated Sheet – Products

Wanzhi Group is a Chinese supplier of metal material factories, offering production of coated and galvanized metal coils and deep processing services for various profiled sheets. Contact us for more solutions and pricing!