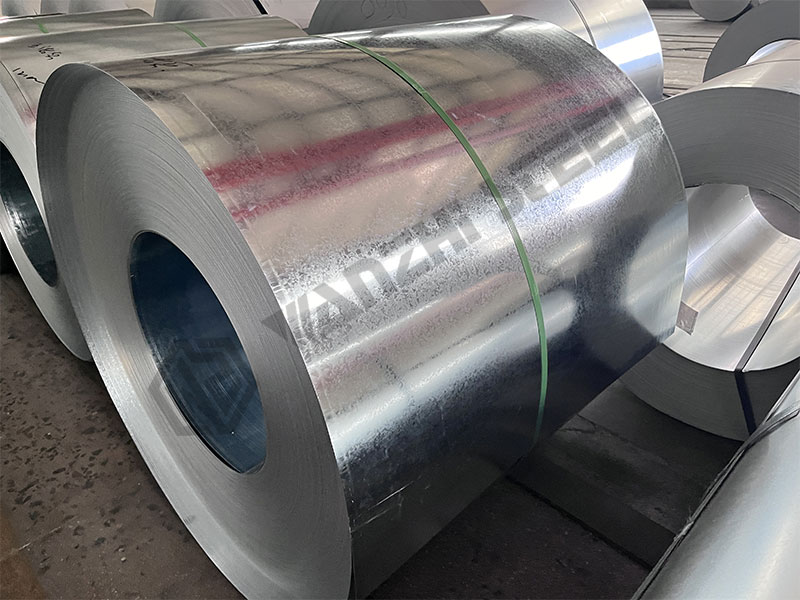

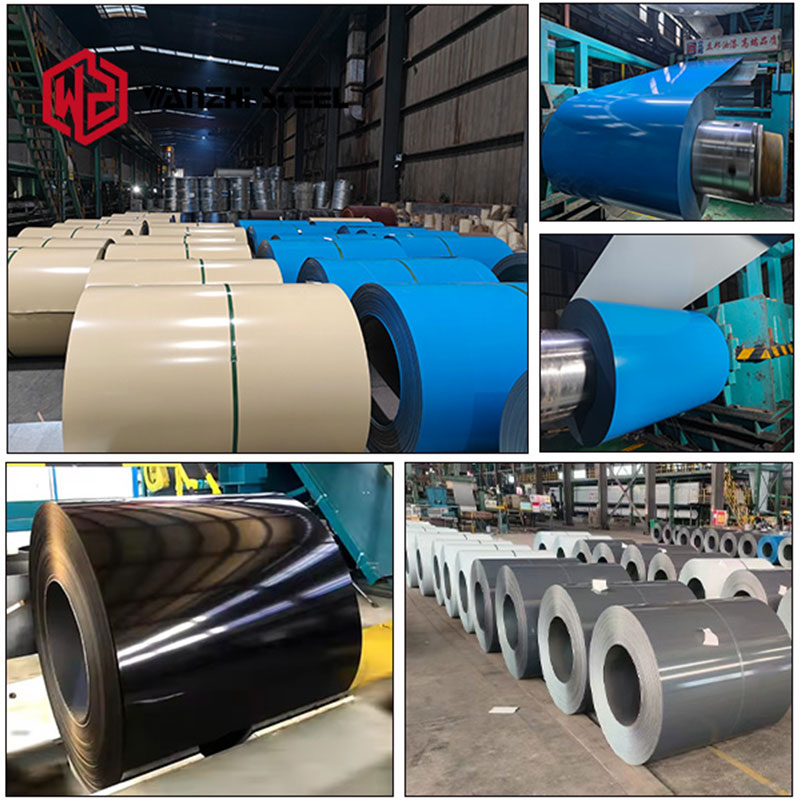

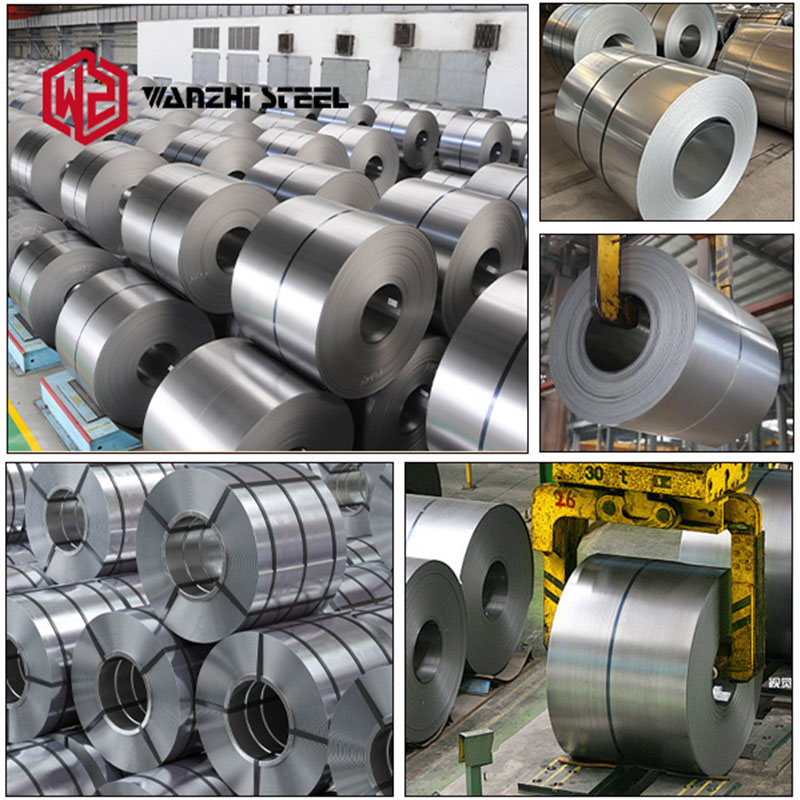

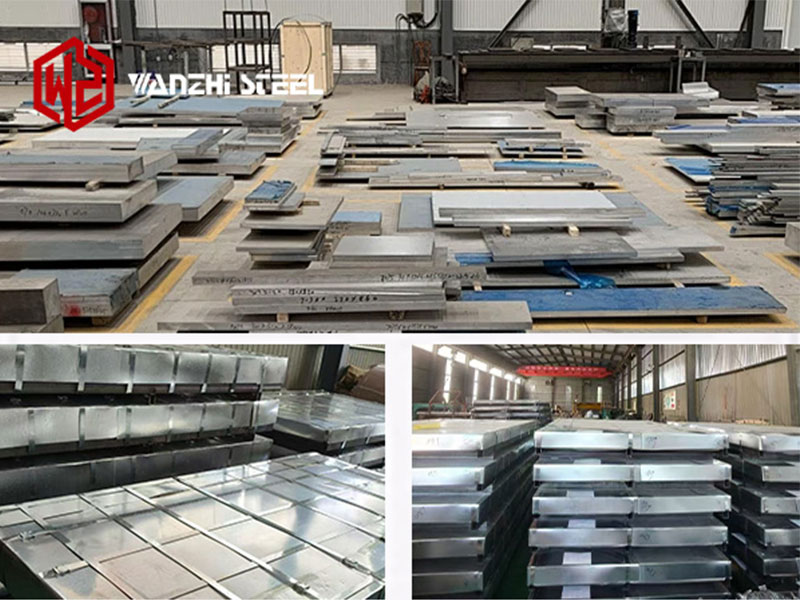

DX51D Z200 High-Zinc-Coated Hot-Dip Galvanized Steel is typically sold in coil (GI coil), sheet (GI sheet), or strip (GI strip) forms. The DX51D base material is suitable for complex forming processes such as deep drawing and stretching. The pure zinc coating provides rust protection. Surface finishes include plain (no zinc spangle), standard zinc spangle, or large zinc spangle.

DX51D Z200 – DX51D

DX51D substrate is the base steel grade for hot-dip galvanized steel sheets (HDG) defined in European Standard EN 10346. Specifically engineered for deep drawing, it withstands complex bending, deep drawing, and stretching operations without cracking or zinc coating detachment. It is primarily used for general-purpose forming applications.

Letter meanings:

- D: Represents “Drawability,” indicating the steel grade is suitable for forming processes such as deep drawing and bending.

- X: Denotes non-structural steel (distinguished from structural steels like S235, S275, etc.).

- 51: Series designation, where D denotes the drawability grade.

Performance Characteristics:

- Yield Strength: Approximately 140-220 MPa.

- Tensile Strength: Approximately 270-410 MPa.

- Elongation: Exhibits good ductility, suitable for stamping, stretching, and similar processes.

- Corrosion Resistance: Provides basic protection through the galvanized coating.

DX51D Z200 – Z200

The thicker the zinc coating on galvanized steel, the better its corrosion resistance. The Z200 zinc coating (i.e., 200 g/m²) provides robust cathodic protection, effectively resisting atmospheric corrosion. It is suitable for indoor or moderately exposed outdoor environments, extending the service life of products.

Galvanized coating weight:

- Z denotes “Zinc,” indicating the steel surface is coated with zinc to prevent corrosion.

- 200 signifies a zinc coating weight of 200 grams per square meter (g/m²), typically referring to single-sided galvanization (i.e., total coating weight may be 200 g/m², or 100 g/m² per side—confirm with supplier).

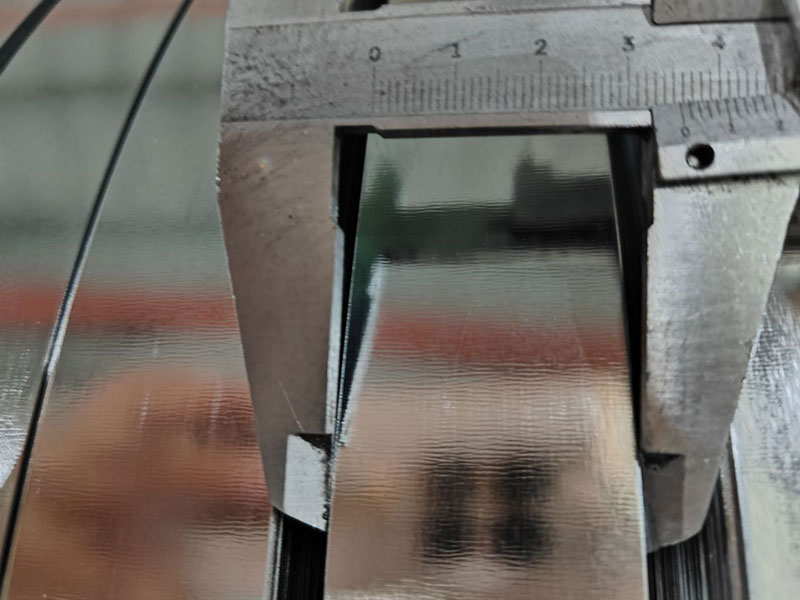

Galvanized Layer Thickness:

- Based on zinc’s density (approximately 7.1 g/cm³), Z200 corresponds to a single-sided galvanized layer thickness of about 14 micrometers (μm).

Specifications

| Parameter | Description |

| Base Material | DX51D (according to EN 10346 standard) |

| Zinc Coating Code | Z200 (Total zinc coating weight: 200 g/m², approximately 100 g/m² per side) |

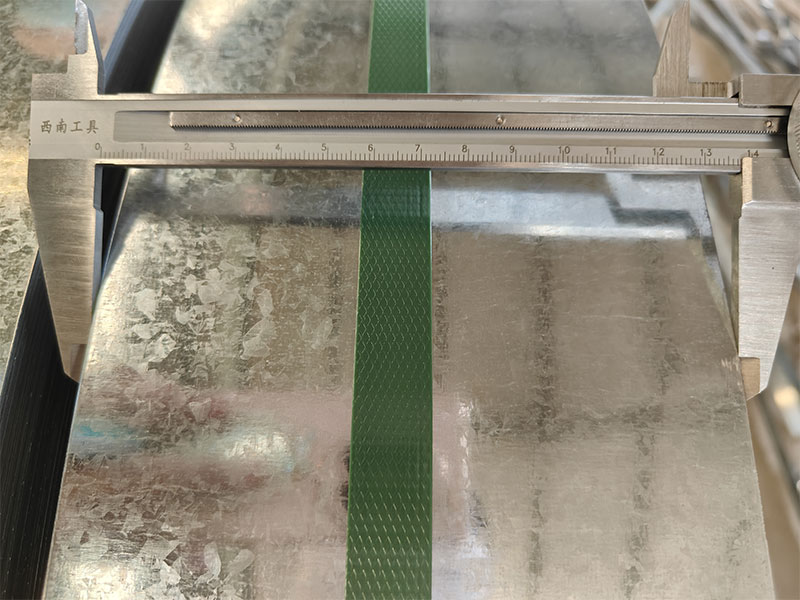

| Standard Thickness | 0.15mm – 6.0mm (customizable) |

| Common Width | 600mm – 1250mm |

| Surface Appearance | No spangle / Small spangle / Regular spangle |

| Surface Treatment | Chromate passivation (anti-white rust), non-chromate passivation (environmental), oil coating, phosphating (enhances paint adhesion) available. |

| Mechanical Properties | Low yield strength and high elongation, easy to form. |

| Standards | EN 10346, ASTM A653 (corresponding grades), JIS G3302, etc. |

Application of DX51D Z200

Wanzhi Group provides high-quality hot-dip galvanized steel solutions and galvanized steel products that deliver tangible economic benefits for applications in construction, automotive, home appliance manufacturing, and other sectors.

- Construction Industry: Roofing, wall panels, gutters, downspouts, etc.

- Automotive Manufacturing: Body panels, chassis components, stamped parts, etc.

- Home Appliance Industry: Washing machine drums, refrigerator shells, kitchen appliances, etc.

- General Manufacturing: Light structural components, ventilation ducts, agricultural equipment, etc.

DX51D vs. DX52D/DX53D/DX54D

| Grade | Characteristics and Applications | Formability | Cost | Applicable Processes |

| DX51D | Used for general bending, light processing, and simple forming. | Good | Low | Simple bending, rolling forming |

| DX52D | Has better ductility, suitable for mechanical interlocking (e.g., flanging) and slightly complex forming. | Better | Medium | Mechanical interlocking, bending |

| DX53D | Has excellent ductility, suitable for deep drawing, stretching, and other complex forming without surface slip lines. | Excellent | Higher | Deep drawing, stretching, complex 3D forming |

| DX54D | Further optimized from DX53D, the highest formability grade. | Excellent | High | Requires extremely high deep drawing and complex stretching parts |

Z200 vs. Z40/Z100/Z150/Z275/Z350

| Zinc Coating Code | Total Zinc Coating Weight (g/m²) | Corrosion Resistance | Application Scenarios | Economic Feasibility |

| Z40 | 40 g/m² | Basic | Dry indoor environments, internal structural parts, products with low appearance and lifespan requirements. | Lowest cost |

| Z100 | 100 g/m² | General | Indoor environments, general outdoor areas, general hardware. | Economical |

| Z150 | 150 g/m² | Good | Most indoor and general outdoor environments (excluding coastal and industrial areas). | High cost-performance ratio |

| Z200 | 200 g/m² | Strong | Universal for indoor and outdoor use, suitable for humid environments, industrial atmospheres. | High cost-performance ratio |

| Z275 | 275 g/m² | Strong Effect | Harsh environments, such as industrial areas, coastal regions, and high humidity zones. | Higher cost |

| Z350 | ≥ 350 g/m² | Ultra-Strong | Extreme environments, such as chemical plants, seaside buildings, etc. | High cost |

DX51D Z200 Galvanized Steel Factory

Wanzhi Group is a galvanized steel factory in China. Our facility is located in Boxing County, Binzhou City, Shandong Province, China. Equipped with two galvanized steel production lines, we manufacture galvanized steel coils and sheets in various specifications. We also provide value-added services including bending, slitting, leveling, forming, and stamping.

Certificates

Customization & Services

Dimension Customization: Provide non-standard thickness, width, and cut-to-length shearing.

Surface Treatment Customization: Specify passivation methods (chrome-free/chrome-containing), oil coating quantities, or phosphating based on your subsequent process requirements.

Packaging: Standard export packaging ensures product protection during transportation and storage.

Minimum Order Quantity: 5-10 tons (per coil) negotiable. Inquiries welcome.

Heavier zinc coatings deliver superior corrosion resistance and extended service life. DX51D Z200 galvanized steel offers balanced performance and broad applicability. It meets demanding forming requirements while providing long-term, reliable corrosion protection—making it your trusted partner for manufacturing high-quality products.