Prepainted Galvanized Steel PPGI and Stainless Steel

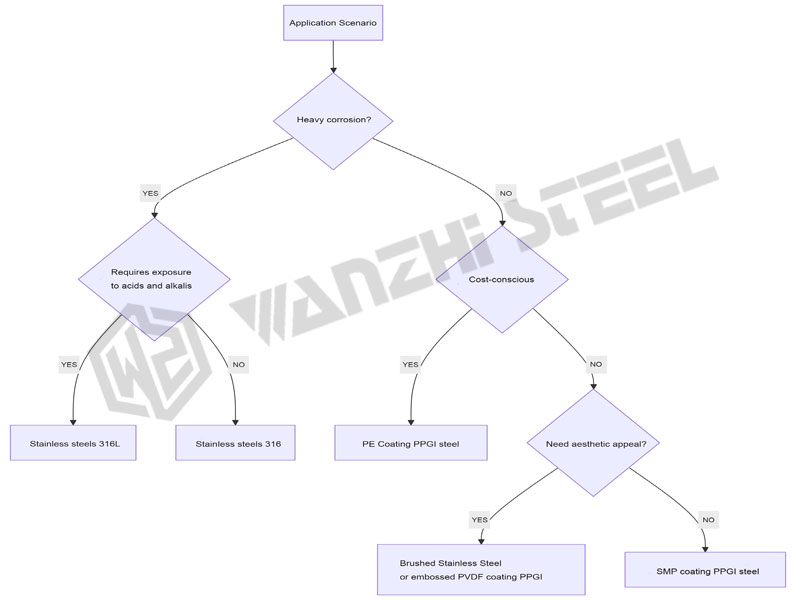

Prepainted Galvanized Steel PPGI steel is the metal of choice for cost-sensitive, short-term use scenarios requiring custom colors/textures (architectural roofs, appliance housings), and Stainless Steel is ideal for permanent projects, highly corrosive/high-temperature environments, and food and medical areas (curtain walls, chemical equipment).

Stainless Steel

Stainless Steel is an alloy steel containing ≥10.5% chromium. It is resistant to oxidation, acid and alkali corrosion by virtue of a passivated film, has a long life and is resistant to high temperatures (up to 800°C), and has a bright and beautiful surface, making it suitable for highly decorative scenes. However, the cost is significantly higher than other coated steels, and the processing is difficult (stamping/welding requires special equipment), and it is mostly used in permanent engineering, food and medical, chemical equipment and other high-end fields.

- Core Advantages: Lifetime rust protection, resistance to extreme environments, strength & hygiene.

- Limitations: High cost, difficult to process

Galvanized Steel + Coating (PPGI)

Galvanized Steel + Coating (PPGI) is an organic coating (e.g. polyester, fluorocarbon) applied to a galvanized substrate (GI/GL) that combines the rust protection of galvanizing with the corrosion protection/decorative features of a coating, providing a rich color texture at a lower cost than stainless steel. Weather resistance is dependent on the coating grade (PVDF is suitable for outdoor use), and maintenance is required in harsh environments. It is widely used in appearance and cost-sensitive areas such as architectural roofs and walls, appliance housings, and automotive parts.

- Core Advantages: Low cost, lightweight, aesthetically pleasing and customizable.

- Limitations: Rust-prone cuts, coating-dependent lifespan

Differences

- Corrosion protection: stainless steel over PPGI prepainted galvanized steel;

- Cost: PPGI is lower than stainless steel

- Applications: PPGI more cost-effective, stainless steel heavy duty for extreme environmental durability.

Prepainted Galvanized Steel PPGI and Stainless Steel Properties

Before selecting the right metal for a project, it is important to have a complete understanding of the physical, mechanical, corrosion resistance and machinability of the different materials, as well as the properties of the steel and the environment in which it is to be used, in order to select the most cost-effective solution for the project. In the following section, Wanzhi Group will familiarize you with the core properties of galvanized and painted steel compared to stainless steel.

Physical Properties Comparison

PPGI (Painted Galvanized Steel)

- Base material: Mild steel

- Density: 7.85 g/cm³

- Coefficient of thermal expansion: 12.0 × 10-⁶/K (20-100℃)

- Thermal conductivity: 50.0 W/m-K (substrate contribution)

- Characteristics: Galvanized layer to enhance corrosion resistance, low-temperature expansion characteristics suitable for large temperature difference scenarios.

304 stainless steel

- Density: 7.93 g/cm³

- Coefficient of thermal expansion: 17.3 × 10-⁶/K (20-100℃)

- Thermal conductivity: 16.2 W/m-K

- Characteristics: Higher thermal expansion rate needs to be reserved for expansion space, thermal conductivity is significantly lower than PPGI.

Mechanical Properties

PPGI

- Tensile strength 270-550 MPa

- Yield strength 140-340 MPa

- Elongation 18%-40

- Hardness 120-160 HV (coated +5-10 HV)

304 Stainless Steel

- Tensile strength 515-620 MPa

- Yield strength 205-310 MPa

- Elongation 40%-60

- Hardness 200-250 HV

Note: PPGI base materials are available in high-strength steel (e.g., 340 MPa grade), and stainless steel is available in hardened versions (e.g., 440C hardness up to 580 HV).

Anti-corrosion properties

PPGI

- Neutral salt spray test 1000-2000 hours without red rust

- CCT cyclic corrosion 80-120 cycles

- Acid resistance (pH=2) 72 hours coating blistering

- Alkali-resistant (pH=12) 168 hours without change

316L stainless steel

- Neutral salt spray test >5000 hours without pitting corrosion

- CCT cyclic corrosion >200 cycles

- Acid resistance(pH=2) No corrosion

- Alkali resistance (pH=12) No corrosion

Environmental resistance

PPGI

- Long-term temperature resistance ≤120℃

- Low-temperature toughness -40℃ passes impact test

- UV aging (2000h) ΔE≤5.0 (color difference controllable)

- Abrasion resistance 30-50 L/μm >200

304 stainless steel

- Long-term temperature resistance ≤400℃

- Low temperature toughness -196℃ liquid nitrogen environment stability

- UV aging (2000h) No visible discoloration

- Abrasion resistance >200 L/μm (better after hardening)

Processing and Installation

PPGI

- Molding: Easy to mold by stamping (R/t≥1), compatible with standard molds

- Welding: not weldable (high temperature destroys coating), relies on mechanical connection

- Cutting: laser/shear feasible, corrosion protection required for cuts

- Maintenance: high cost of repair after coating damage

304 stainless steel

- Forming: stamping requires anti-hardening, annealing is often required

- Welding: support TIG / MIG welding, need argon protection against oxidation

- Cutting: waterjet/plasma cutting without the risk of corrosion

- Post-treatment: must be pickled and passivated after welding, complex processes

- Cost: Processing cost is about 30% higher than PPGI

Application Scenarios

PPGI steel Typical application scenarios: architectural roofs/walls, appliance housings, automotive interiors, photovoltaic mounts (cost-sensitive + lightweight scenarios). Stainless steel application scenarios: chemical piping, medical equipment, coastal construction, high-end kitchenware (high corrosion/permanent scenarios).

PPGI (color coated galvanized steel) Application Guide

Building Envelope Systems

- Scenarios: industrial plant roofs/walls, warehousing and logistics centers, temporary showrooms.

- Requirements: Low cost, quick installation, weather resistance (15-25 years).

- Recommended model: DX51D+Z (galvanized layer ≥120g/m²) + PVDF coating (UV resistant, color difference ΔE<5.0)

Home Appliances & Household Goods

- Scenarios: refrigerator/washing machine housings, HVAC equipment housings, office furniture.

- Requirements: Decorative surface, economical, medium abrasion resistance.

- Recommended type: HX340LAD+Z (high tensile steel, yield strength 340MPa) + PE coating (low cost, colorful)

Heat dissipation components

- Scenario: Kitchenware base, electrical appliance heat sink, LED light backplane.

- Requirements: High thermal conductivity (>40 W/m-K), lightweight.

- Recommended model: DC01+Z (mild steel, thermal conductivity 50 W/m-K) + silicone-modified polyester (temperature resistance 150°C)

Stainless Steel Application Guide

Severe corrosive environments

- Scenario: Coastal building railings, chemical pipelines, desalination equipment.

- Requirements: Lifetime maintenance-free, chlorine ion corrosion resistance (salt spray >5000h).

- Recommended type: 316L (00Cr17Ni14Mo2), 2205 duplex (S32205)

Food and Medical Equipment

- Scenarios: surgical instruments, food processing countertops, pharmaceutical tanks.

- Requirements: sterile surface (Ra≤0.8μm), acid and alkali sterilizer resistant.

- Recommended type: 304 (06Cr19Ni10), 316L.

High temperature and wear-resistant parts

- Scenario: vapor exhaust pipe, industrial wear-resistant liner, bearing.

- Requirements: temperature resistance >400℃, high hardness (>250 HV).

- Recommended type: 310S (0Cr25Ni20), 440C (9Cr18Mo).

PPGI pre-painted galvanized steel is recommended for limited budgets + medium environments, and stainless steel is recommended for maintenance-free lifetime + extreme environments. If you have any steel specification or material you are interested in, please feel free to leave a message and Wanzhi Group will provide you with a free quote.