What Are PPGI and PPGL?

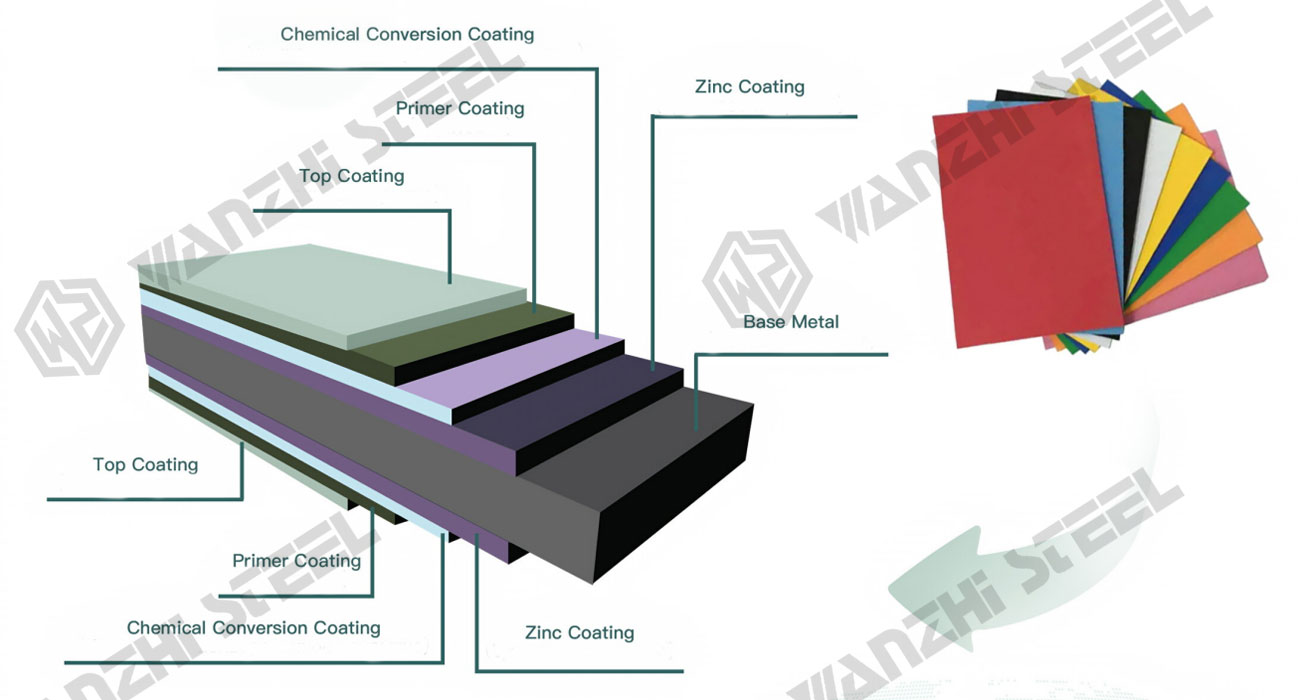

PPGI and PPGL steel is color-coated steel (prepainted steel), usually produced and sold in coils or sheets, which can be slit, bent, stamped, punched, molded, and other deep processing. (Wanzhi Group provides further processing services).

PPGI: Pre-painted galvanized steel, made by coating galvanized iron (GI) with an organic layer (e.g. polyester, PVDF).

PPGL: Pre-painted aluminized zinc-plated steel, made by coating an organic layer on an aluminum-zinc alloy (GL, 55% aluminum + 43.4% zinc + 1.6% silicon).

Key Differences between PPGI and PPGL Steel

Although PPGI steel and PPGL steel are very similar in appearance, there are significant differences in substrate composition, properties, and application environments.

PPGI PPGL Base Material Composition

| Characteristics | PPGI | PPGL |

| Substrate | Galvanized steel (GI) | Galvalume (GL) |

| Coating | Zinc | 55% Al, 43.4% Zn, 1.6% Si |

Comparison of PPGI PPGL Properties

| Properties | PPGI | PPGL |

| Corrosion Resistance | Good | Excellent |

| Heat resistance | up to 200°C | up to 315°C |

| Lifespan | 15-25 years | 25–50 years |

| Cost | Lower cost | Higher cost |

| Weight | slightly heavier | lighter |

PPGI PPGL Environmental Suitability

PPGI: For mild climates with low humidity and salt exposure.

PPGL: Suitable for harsh environments (coastal areas, industrial zones, high humidity).

Applications of PPGI and PPGL

Combining the performance differences of PPGI steel and PPGL, Wanzhi Group offers the most cost-effective solution for PPGI and PPGL!

PPGI Use Cases

General construction: roofs, wall panels, and sheds in non-corrosive environments.

Household appliances: washing machines, refrigerators, and cabinets.

Interior design: decorative panels, furniture, and partitions.

PPGL Use Cases

Coastal infrastructure: harbors, bridges, and seaside buildings.

High-temperature zones: industrial chimneys, solar panel support, and HVAC systems.

Long-term projects: warehouses, factories, and utilities requiring durability.

How to Choose Between PPGI Steel and PPGL Steel?

Consider Performance Needs

Corrosion resistance: Choose PPGL steel in coastal, chemical, or high-humidity areas.

Budget constraints: Choose PPGI for cost-sensitive projects in mild climates.

Heat resistance: PPGL excels in high-temperature environments.

Consider Project Longevity

Short-term (10–20 years): PPGI offers a cost-effective solution.

Long-term (25+ years): PPGL’s extended durability justifies higher upfront costs.

Environmental Factors

Humidity/Salt Exposure: PPGL’s aluminum-zinc alloy resists salt spray and moisture.

UV Exposure: Both support UV-resistant coatings (e.g., PVDF), but PPGL’s underpayment adds protection.

Aesthetic Requirements

Colors and finishes: Both PPGI and PPGL offer customizable colors (RAL, Pantone), patterns (wood, stone), and finishes (gloss, matte).

PPGI PPGL Cost Benefit Analysis

| Aspect | PPGI | PPGL |

| Initial cost | low | high |

| Maintenance cost | Higher | Lower |

| ROI | Suitable for short-term projects | Suitable for long-term investment |

PPGI PPGL Customization Options

If you want to customize PPGI PPGL materials for your project, Wanzhi Group is your ideal partner. We have 3 prepainted steel production lines, which can be customized in terms of substrate material grade, thickness, width, coatings, patterns, finished panels, sandwich panels, glossy surfaces, etc. (We also accept design and production based on samples or drawings). (We also accept design and production based on samples or drawings. ).

- Coating: PE, SMP, PVDF, HDP.

- Thickness: 0.12mm-1.5mm.

- Pattern: Brick, wood, marble, flower, grass, fish, traffic warning pattern, etc.

- Finished products: corrugated sheet, trapezoidal sheet, or flat sheet.

Supplier Recommendation – Wanzhi Group

China is the main source of PPGI and PPGL steel in the world. China-coated steel suppliers offer competitive prices and advanced manufacturing technology. Wanzhi Group is a certified China supplier (ISO 9001, ISO 14001), we PPGI/PPGL customized service and support third-party inspection (e.g. SGS, BV).

Frequently Asked Questions

Q1: Can PPGL coil replace PPGI coil in all applications?

A: No. PPGL coil is better suited for harsh environments, while PPGI coil is cost-effective in mild conditions.

Q2: Which is more environmentally friendly?

A: Both are recyclable, but PPGL lasts longer and reduces waste over time.

Q3: How can I verify the quality of the coating?

A: Request a salt spray test report (ASTM B117) and check for certifications (e.g. ISO).

Q4: What is the price difference between PPGI and PPGL?

A: PPGL costs 20-40% more because it is based on aluminum-zinc.

Q5: Can I get samples before ordering in bulk?

A: Yes, Wanzhi Group provides samples for testing.

Q5: Can I ask my agent or third-party organization to inspect the factory?

A: Yes, you can visit our factory before and after production.

Choosing between PPGI and PPGL depends on your project’s environmental needs, budget, and service life requirements. For harsh climates and long-term durability, PPGL is unrivaled. For cost-effectiveness in mild conditions, PPGI is still a reliable choice. You can also contact Wanzhi Group for a professional solution.