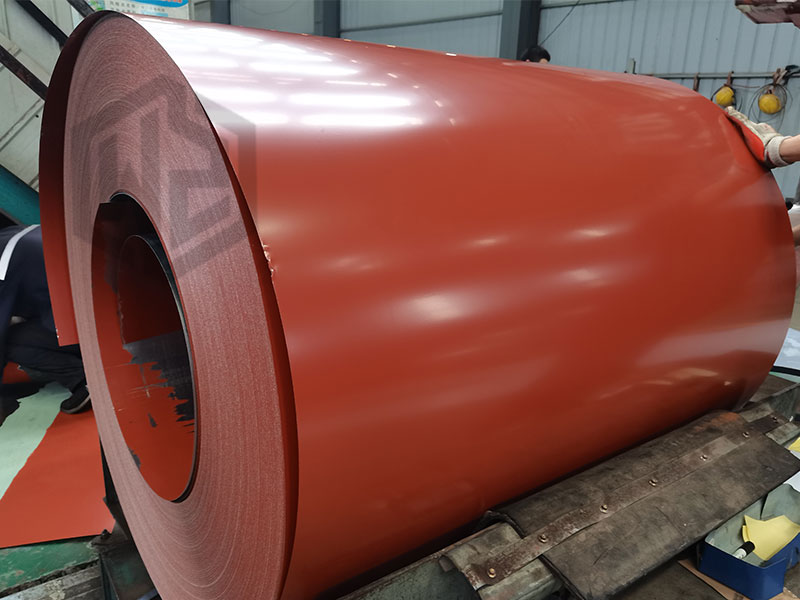

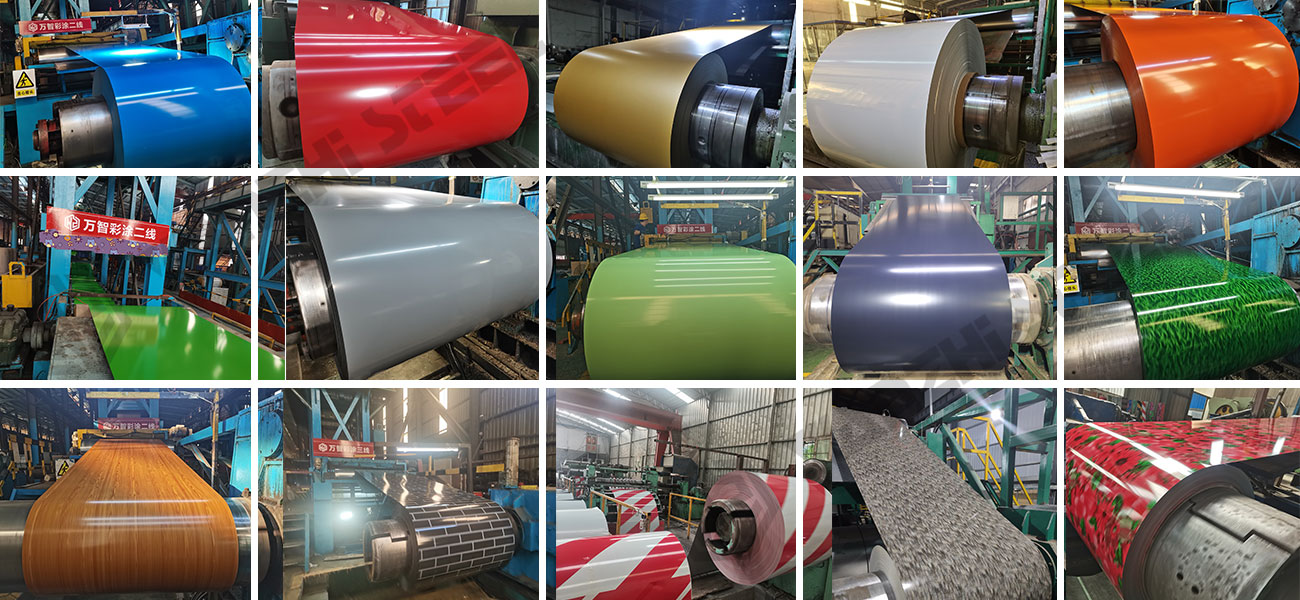

PPGI (Prepainted Galvanized Iron) steel coils are widely used in many industries, such as construction, home appliances, electronics, infrastructure, decoration, transportation, electricity, new energy, advertising, and so on, because of their corrosion resistance, decorative and multifunctional properties, lightweight and high strength, easy processing, environmental protection, low maintenance, etc.

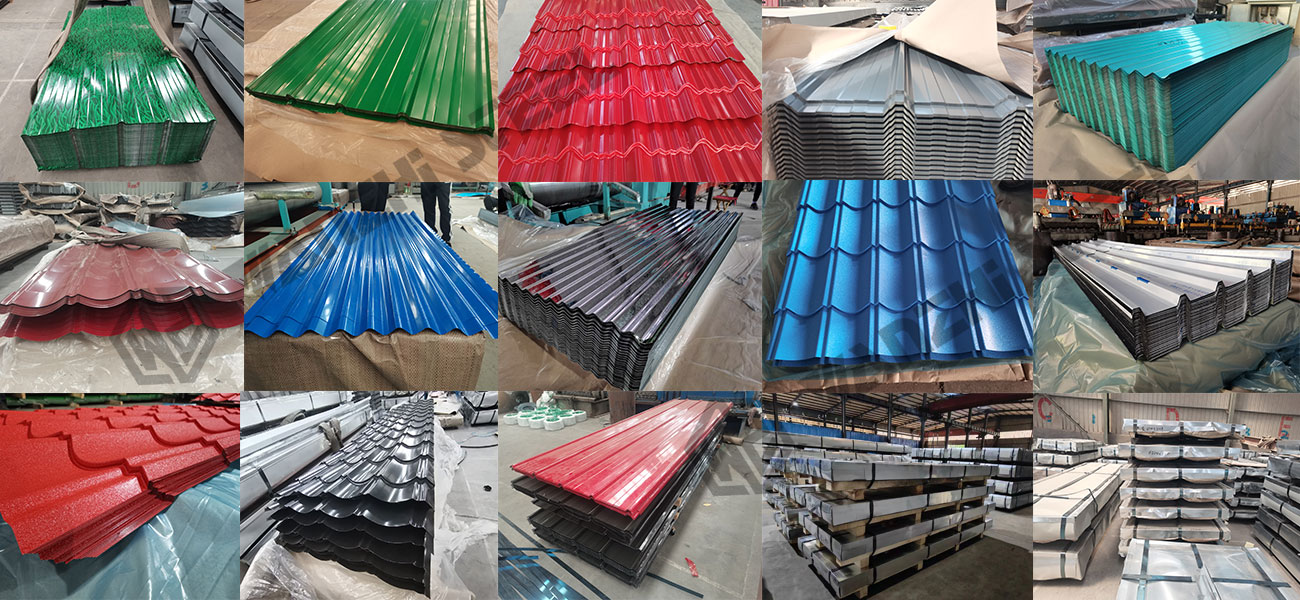

Construction & Infrastructure

PPGI coil and PPGI sheet are commonly used for roofing, wall coverings, facade decoration of high-rise and commercial buildings, thermal insulation, and fireproofing materials.

Roof and wall systems

- Industrial buildings: PPGI has the advantages of UV and wind pressure resistance (≥1.5kN/m²), and has a service life of 15-30 years outdoors.

- Commercial buildings: shopping center color-coated curtain wall, rich in color and good weather resistance, light retention rate > 90% (QUV 2000 hours).

Interior decoration

- Ceiling and partition: beautiful, fireproof (fire rating B1).

- Elevator interior: antibacterial coating, in line with hospital cleanliness standards.

Home Appliances & Consumer Electronics

PPGI steel is also a popular material for home appliance manufacturing, commonly used in the external shell of refrigerators, air conditioners, washing machines, microwave ovens and other home appliances, kitchen utensils, electrical accessories production, etc.

Appliance shell

- Refrigerator/washing machine: choose HDP PPGI coil, anti-fingerprint and detergent resistant.

- Oven/Microwave: SMP PPGI coil (temperature resistance 120℃), color stability.

Electronic products

- Control cabinet/chassis: Surface coated with conductive coating.

- Battery casing: surface overcoated with insulating coating to prevent short circuits.

Transportation

PPGI coils have a wide range of applications in automobile manufacturing, such as exterior steel sheets and interior parts of automobiles, such as roofs, door panels, engine covers, and so on.

Automobile manufacturing

- Body parts: SMP-coated PPGI steel coil, resistant to stone impact and snow melting salt.

- Truck compartment: Z180+PE coating PPGI steel coil, rust resistant and lightweight.

Rail transportation

- Subway interior panel: fireproof coating.

- High-speed rail roof: streamlined PPGI sheet, reduced wind resistance, self-cleaning surface coating.

Industrial and Energy Equipment

PPGI coil as a raw material is ideal for industrial equipment, power facilities, substations, and other energy equipment housing materials.

Industrial equipment housings

- Distribution boxes/control cabinets: Z120 plated + PE coated PPGI coil, IP54 protection class.

- Chemical piping: fluorocarbon coated PPGI coil (acid and alkali pH 1-14 resistant), chemical corrosion resistant.

New energy facilities

- Photovoltaic mounts: SMP-coated PPGI, resistant to humidity and heat (85°C/85% RH), salt spray test >800 hours.

- Wind turbine cover: high-strength steel substrate (S550GD) + PVDF coated PPGI, resistant to wind and sand erosion.

Agriculture and cold chain logistics

PPGI coil has a wide range of applications in agriculture such as agricultural greenhouses, trellises and barns, storage facilities, equipment protection, fencing and guarding, agricultural buildings, drainage systems, etc.

Agricultural facilities

- Greenhouse skeleton + roof covering material: Z120 plating + anti-rust coating, resistant to ammonia corrosion, life span 10–15 years.

- Grain bin enclosure + feeding facilities: sandwich panel structure (EPS core), heat preservation, and moisture resistance.

- Enclosure and fencing.

Cold storage construction

- Low-temperature cold storage (-25℃): PU sandwich panel.

- Cold chain vehicles: lightweight PPGI sheet to reduce energy consumption.

Advertising and Public Facilities

PPGI coating has anti-corrosion and weather-resistant features, which are suitable for billboards, displays, roofs, open-air gymnasiums and other applications that are exposed to the outdoor environment for a long time.

Signage

- Outdoor billboards: PVDF coated PPGI rolls, weather resistant for 20 years +, support high definition spray painting.

- Exhibition Display: Mirror effect PPGI rolls, reflectivity ≥80%.

Public facilities

- Bus stop roof: self-cleaning coating, reducing maintenance frequency.

- Stadium seats: wear-resistant coating.

Suggestions for PPGI Coil

Wanzhi Group offers PPGI coils with zinc coatings from 30-275g, thicknesses from 0.12-1.5mm, coatings from PE/SMP/HDP/PVDF/PVC/PU, and varnishes from 5 to 40 microns, providing cost-effective solutions for different application scenarios.

| Application | Recommended plating + coating | Key parameters |

| Coastal buildings | Z275 plating + PVDF coating | Salt spray test > 3000 hours |

| High humidity industrial areas | Z180 plating + SMP coating | resistance to heat and humidity cycles |

| Food Processing Plant | Food Processing Plant | Coating Thickness ≥20μm |

| High-temperature workshop | Temperature-resistant SMP coating | T-bend test 1T no cracks |

Advantages of PPGI

PPGI steel, GI steel, and stainless steel are popular metal materials and common steel solutions for construction, and industrial applications. Compared to galvanized steel and stainless steel, PPGI combines aesthetics, practicality, and cost-effectiveness, making it one of the ideal metal materials for outdoor use.

Comparison with Other Materials

| Material | Advantages | Disadvantages |

| PPGI | low cost, corrosion resistant, colorful | Lower strength than stainless steel |

| Stainless steel | high strength, long life | High cost (3-5 times more than PPGI) |

| galvanized sheet/ | lower price | Non-decorative needs secondary painting |

Benefits of PPGI Coil

Leave a message to tell us the PPGI coil specification, size, and application you need, and get a free quote from Wanzhi Group!