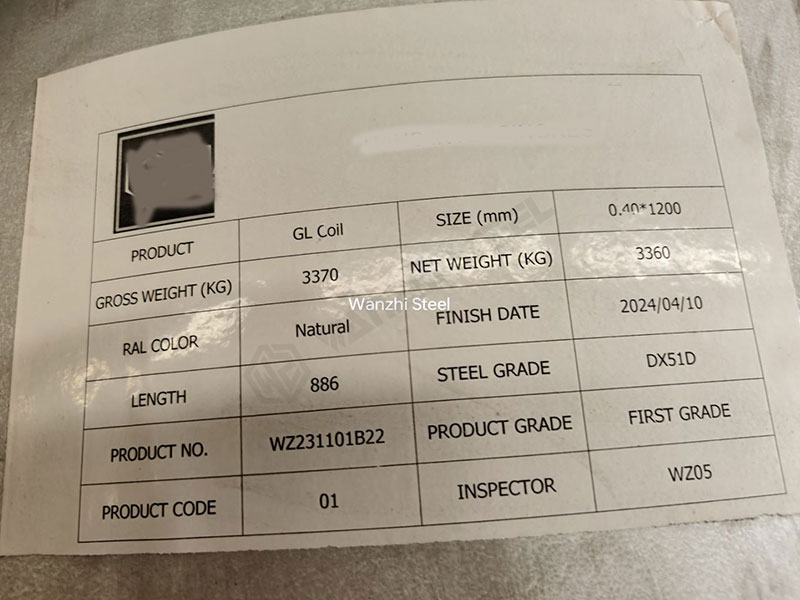

| Substrate | Galvalume (aluzinc) |

| Paint | PE, SMP, PVDF, HDP |

| Services | Slitting, bending, punching, molding, etc. |

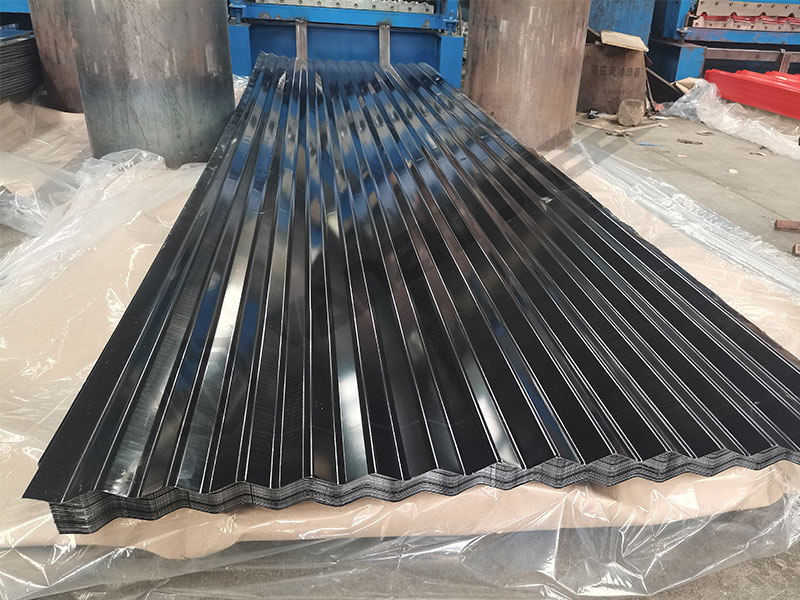

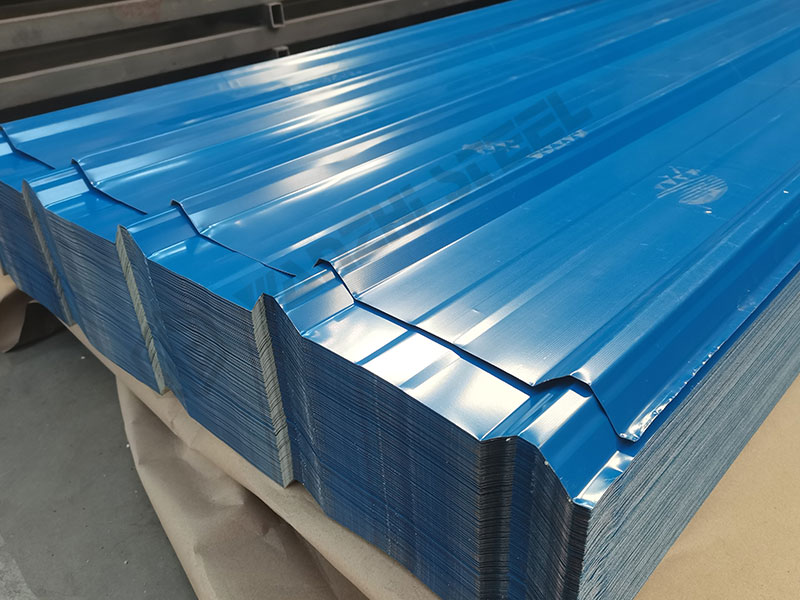

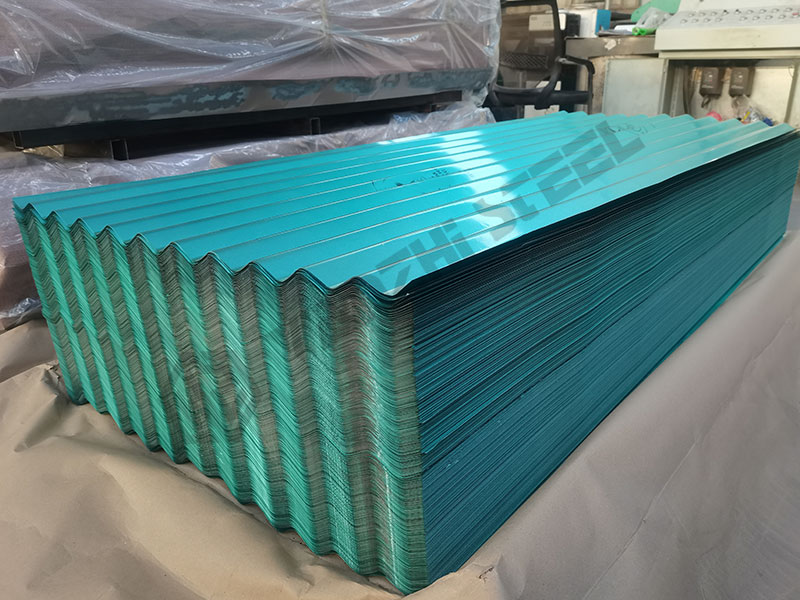

What is PPGL Corrugated Sheet Materials?

The full form of PPGL corrugated sheet is prepainted galvalume steel corrugated sheet, which is PPGL steel processed through cold forming technology with a corrugated surface, it combines the corrosion and durability of galvalume steel, the decorative and weathering properties of paint, and the structural stability of corrugated sheet, is a high-quality building material.

How Much Does the PPGL Corrugated Sheet Cost?

The cost of a corrugated metal sheet includes a variety of factors such as thickness, width, length, zinc coating, material, roll weight, paint type, paint film thickness, color, etc. If you have a drawing of your corrugated sheet, Wanzhi Group can provide you with an accurate quote.

PPGL Corrugated Sheet Price

The price of regular material, size, and surface treatment of PPGL coil is 650-900USD per ton, PPGL corrugated sheet is more expensive than PPGL steel coil because of the additional processing fee. The price of special paint, surface size, board shape, and pattern is also different, contact us via WhatsApp to get a quote!

PPGL Sheet Weight Calculation

How do I calculate the weight of each sheet by myself? How many sheets per ton? We have a simple formula to calculate the weight of a steel plate: Weight of a single piece of steel sheet(KG)=7.85(density)*thickness (mm)*length(m)*width(m). Of course, leave a message (email) to tell us the product specification you need, and we can help you calculate!

What is The PPGL Corrugated Sheet Used for?

The excellent physical and decorative properties of PPGL steel and the unique surface structure of corrugated sheets make PPGL corrugated sheets a key player in modern construction.

Advantages of Prepainted Galvalume Corrugated Sheet

- Lightweight: Aluminum alloys have low density and low mass.

- High strength: Steel sheets have high strength.

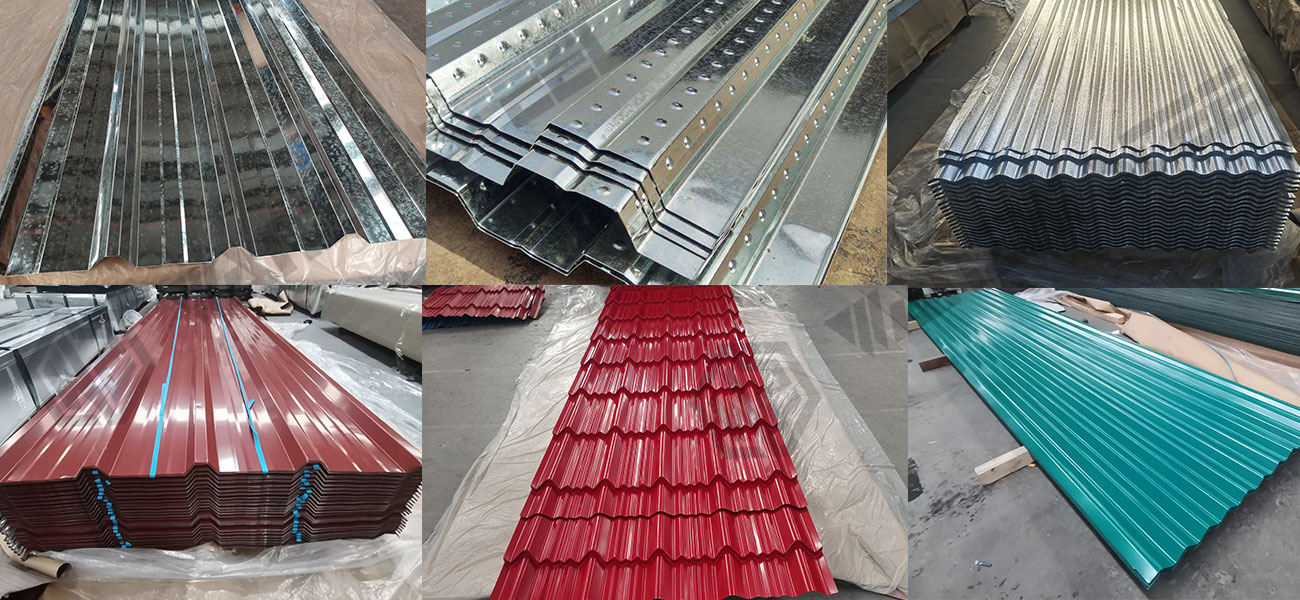

- Colorful: PPGL colors can be customized.

- Various surface effects: printed, stamped, matt, wrinkled/Textured, glossy, and other surface effects.

- Fireproof: The metal sheet has a certain fire resistance.

- Corrosion resistance: Zinc-aluminum alloy coating with paint coating increases corrosion resistance, high-temperature resistance, and durability.

- Easy to install: Modular design, easy to install and use.

- Structural Stability: The corrugated shape design increases the stamping resistance of PPGL steel.

- Rainproof: The corrugated surface design also increases drainage and is waterproof.

Uses of PPGL steel

- Building Roofing: Large-span steel structures and small-span roof coverings, residential and commercial building roofs.

- Wall coverings: Wall and interior wall coverings, ceilings, etc. for residential, commercial, and industrial buildings.

- Sandwich panels: as raw material for the production of sandwich panels.

Where to Buy PPGL Corrugated Sheet?

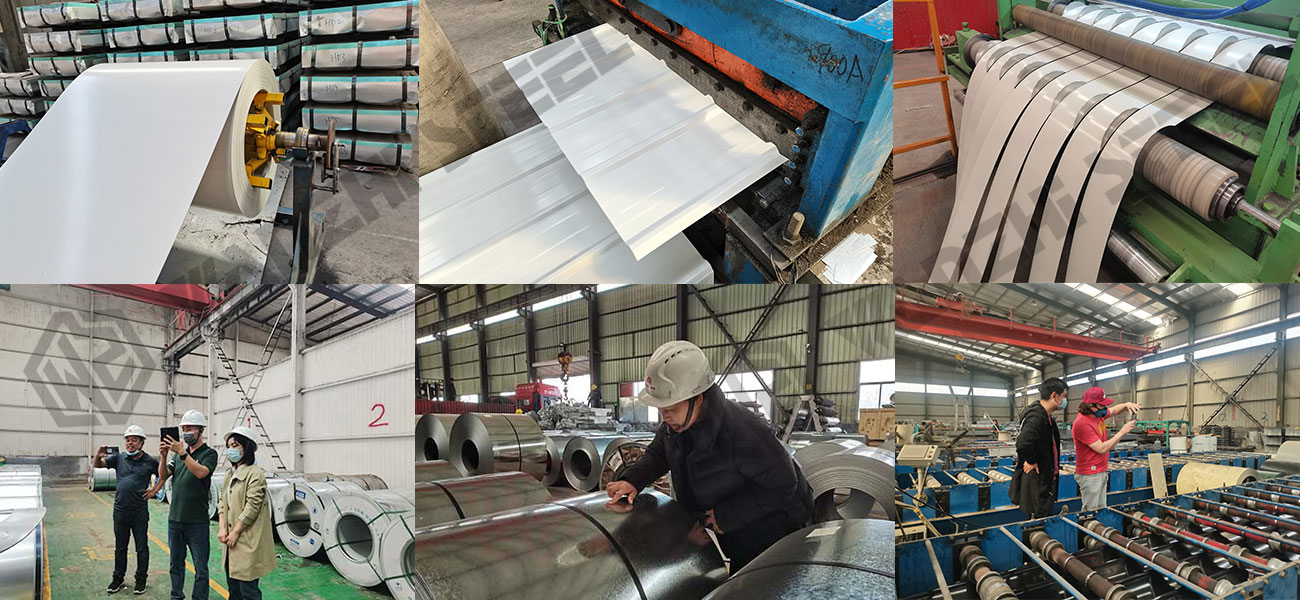

Where to buy Premium PPGL steel corrugated sheet in Wanzhi. Wanzhi Group factory has PPGI PPGL production line, many kinds of forming machines, slitting machines, and stamping equipment, providing high quality and competitive price PPGI PPGL steel sheet, coil, strip, panel, etc. for different color coated steel purchasing in other fields in various countries.

PPGI PPGL Factory – Wanzhi

ISO9001-certified color-coated steel factory, 3 color-coated production lines, an annual production capacity of 600,000 tons, can be customized according to the choice of material, specification, paint film, pattern, plate type, weight, packaging, etc. Production lead time is 5–45 days, contact us for samples!

PPGI PPGL Supplier

As a professional PPGL corrugated sheet supplier, we have rich experience (we started the export business in 2011), with various materials (Q195-Q345, G30, G60, G90, SGCC, SGCD1, SGCD2, SGCD3, SGC340, SGC400, SGC440, DX51D, DX52D, DX53D, DX54D), mature production process (hot-dip galvanizing, electro-galvanizing, pickling, painting, deep processing), verified by CE, ISO, JIS, AISI, ASTM, DIN.

Cases and Project

Various types of corrugated metal sheets, and raw materials of corrugated sheets (steel coils, steel plates) have been exported to Chile, Peru, Colombia, Turkey, Azerbaijan, Philippines, Singapore, Thailand, Indonesia, UAE, Saudi Arabia, Turkmenistan, and so on to 100 countries and regions.

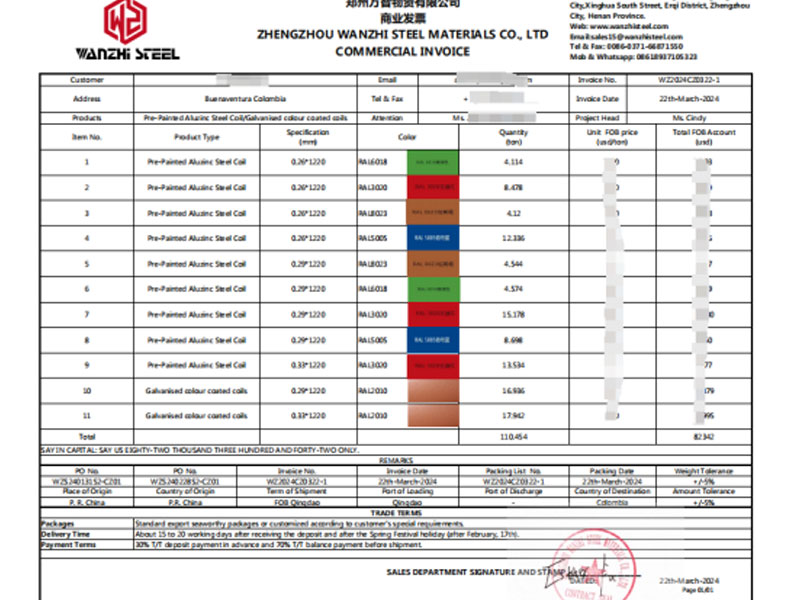

27 Ton PPGL Steel to Peru

100 tons of GL and PPGL in Solomon Islands

110 tons of PPGI and PPGL in Colombia

How to Make Color-Coated Corrugated Sheet?

Structure of PPGI PPGL corrugated sheet: substrate, metallic coating, chemical conversion layer, primer, topcoat. The metal coating protects the steel from water, oxygen, salt spray, and other chemicals that may cause rust, while the paint layer enhances the corrosion resistance, decorative qualities, high-temperature resistance, and durability. The production process mainly includes galvanizing/alloying, painting, and forming.

- Galvanizing: Cold rolled steel plate is selected as the substrate, the surface is cleaned and then coated with a layer of zinc-aluminum alloy.

- Color Coating: The finished aluzinc steel is roll-coated with one or more layers of paint, which is then dried and cured to ensure that the coating is tightly bonded to the steel.

- Forming: The PPGL steel is fed into a cold-forming machine to customize the shape and size of the corrugated sheet according to the selection.

How to Choose Between PPGI and PPGL Corrugated Sheet?

PPGI and PPGL are two popular prepainted corrugated sheet materials that are widely used for building roofs, façade decoration, warehouses, sheds, fences, windows, doors, and billboards. The difference between PPGI corrugated sheet and PPGL corrugated sheet lies in the use of different metal substrates, while the similarity lies in the same range of choices in color, paint film, paint material, sheet shape, surface treatment, and surface structure.

When Using a Painted Corrugated Galvanized Sheet (PPGL)?

PPGI steel is a low-cost, corrosion-resistant material with a life expectancy of 15–30 years, suitable for use in mild climates and less corrosive areas.

When Using a Painted Corrugated Galvalume Sheet (PPGL)?

PPGL steel has a relatively high cost and a corrosion resistance of 30–50 years and is suitable as a building material in areas with high temperatures and harsh environments, such as the sea, heavy industry, etc.

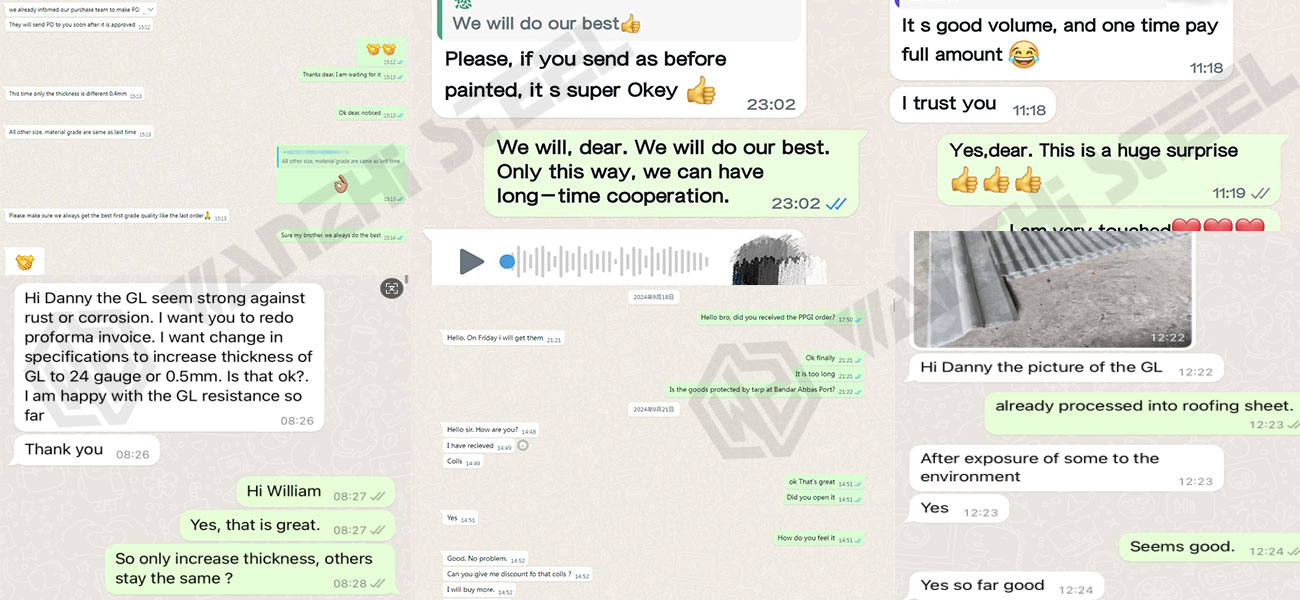

Wanzhi PPGL Feedback

Take a look at the PPGI PPGL steel coil and sheet for roofing and wall for sale in Wanzhi to see the feedback received from our customers!

Want to customize PPGL corrugated sheet or other metal corrugated? Send us the drawing by email, we will provide you the production plan and price!