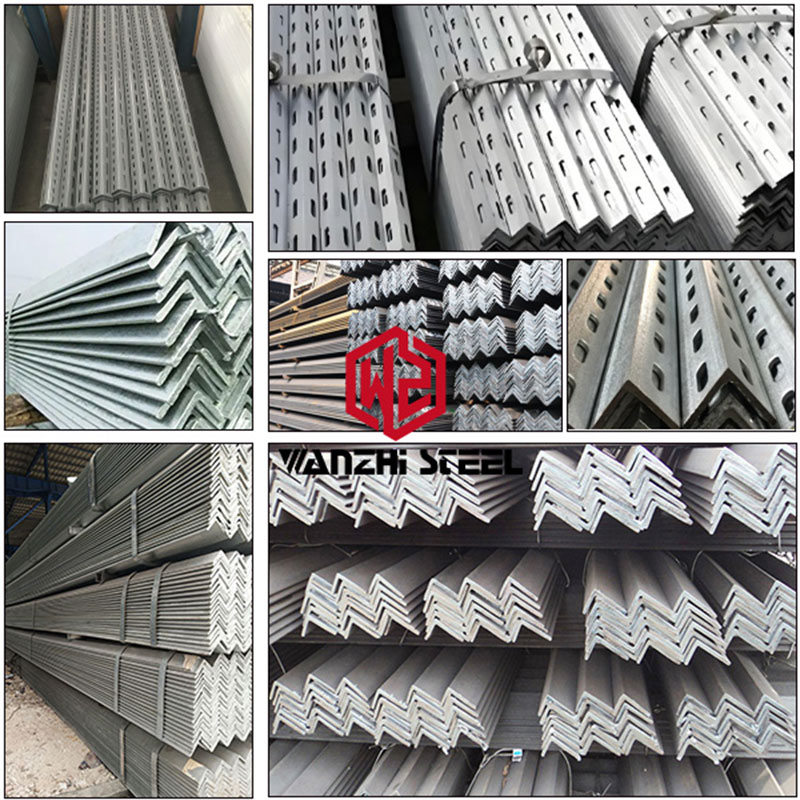

Galvanised steel tube come in various forms, including round tubes and square tubes. They combine the high strength of steel pipe with the long-term corrosion resistance of a zinc coating, making them a core material for fluid conveyance and structural support. Wanzhi Group provides OEM/ODM services for a full range of GI tube products, covering standard pipes for conveyance, thickened pipes for structural use, and customized special-purpose pipes.

Classification and Application of Galvanised Steel Tubes

Galvanised Steel Tubes are widely used in water supply and drainage, gas transmission, building structures, agricultural irrigation, industrial piping, and other fields. They are a preferred pipe material offering a balance of cost-effectiveness and practicality. They can be categorized by production process, galvanizing method, application, and cross-section: Round Tube, Square Tube, Welded Pipe, Seamless Pipe, Hot-Dip Galvanized Pipe, Electro-Galvanized Pipe, etc.

Classification by Production Process

- Galvanised Welded Steel Pipe: Made by welding coiled steel sheet/strip into a pipe, then galvanizing. Features low cost, high efficiency, and flexible specifications. It is the mainstream choice for construction, water supply, gas, scaffolding, etc.

- Galvanised Seamless Steel Pipe: Made by piercing a solid billet and hot-rolling it into a pipe, then galvanizing. Has no weld seam, offering higher pressure-bearing capacity and better uniformity. Suitable for high-pressure fluid transport, hydraulic systems, bearing sleeves, and other critical structures.

Classification by Galvanizing Process

- Hot-Dip Galvanized Steel Pipe (HDG): The steel pipe is immersed in molten zinc to form a composite coating of zinc-iron alloy layers and a pure zinc layer. Features a thick coating, long service life, and strong adhesion. It is the preferred choice for outdoor, underground, and corrosive environments.

- Electro-Galvanized Steel Pipe (EG): A uniform pure zinc layer is formed on the pipe surface through electrolysis. The coating is thin (typically 5–20μm), with a smooth, aesthetically pleasing surface. However, its corrosion resistance life is relatively shorter. Mostly used for indoor dry environments or electrical components and furniture requiring high surface quality.

Classification by Primary Use

- Galvanized Steel Pipe for Low-Pressure Fluid Conveyance: Used for transporting general-pressure fluids like water, gas, air, and oil. A traditional material for building water supply/drainage, HVAC, and fire sprinkler systems.

- Galvanized Steel Pipe for Structural Use: Used in building trusses, columns, towers/masts, scaffolding, bridge auxiliary components, etc. Requires higher dimensional accuracy and mechanical properties.

- Galvanized Steel Pipe for Mechanical Structures: Used in manufacturing mechanical parts, automotive drive shafts, agricultural machinery frames, etc. Emphasizes machining precision and performance stability.

- Galvanized Steel Pipe for Special Purposes: Includes cable conduit pipes, pipes for solar mounting systems, greenhouse structure pipes, etc., with specific specifications and performance requirements.

Classification by Cross-Section

- Galvanised Round Tube: Cross-section is circular. Primarily used for fluid conveyance (water, gas, oil), agricultural irrigation, and civil piping.

- Galvanised Square/Rectangular Tube: Cross-section is square or rectangular. Commonly used in building structures (curtain walls, supports), municipal guardrails, equipment frames, and new energy mounting systems.

Galvanised Steel Tube Specifications / Dimensions

Wanzhi Group is a professional metal materials supplier. We offer various galvanised steel tube specifications and also support custom sizing.

Standard Specification Parameters (Mainstream for Hot-Dip Galvanized Pipes)

| Nominal Diameter (DN) | Outside Diameter (mm) | Wall Thickness (mm) | Theoretical Weight (kg/m) | Standard Length (m) |

| 15 | 21.3 | 2.75 | 1.26 | 6, 9, 12 |

| 25 | 33.7 | 3.25 | 2.42 | 6, 9, 12 |

| 50 | 60.3 | 3.75 | 5.18 | 6, 9, 12 |

| 80 | 88.9 | 4.00 | 8.38 | 6, 9, 12 |

| 100 | 114.3 | 4.00 | 10.85 | 6, 9, 12 |

| 150 | 168.3 | 4.50 | 18.18 | 6, 9 |

| 200 | 219.1 | 6.00 | 31.52 | 6, 9 |

Customization Options

- Material Customization: In addition to standard Q235 and Q345, we can provide base pipes made from special materials like high-strength low-alloy steel and weathering steel.

- Zinc Coating Customization: Zinc coating weight can be controlled as required, up to 600 g/m² or more.

- OD Customization: Custom outer diameters from 10mm to 500mm.

- Wall Thickness Customization: Standard 0.6–20mm.

- Length Customization: Standard 6m/9m/12m, can be customized to 1–18m cut lengths.

- Special Processing: Value-added services include cut-to-length, beveling, threading, flange welding, drilling, cold bending, internal coating, etc.

- Special Standards: Can be produced according to international standards such as ASTM A53/A123 (US), EN 10240 (EU), JIS G3444 (Japan), etc.

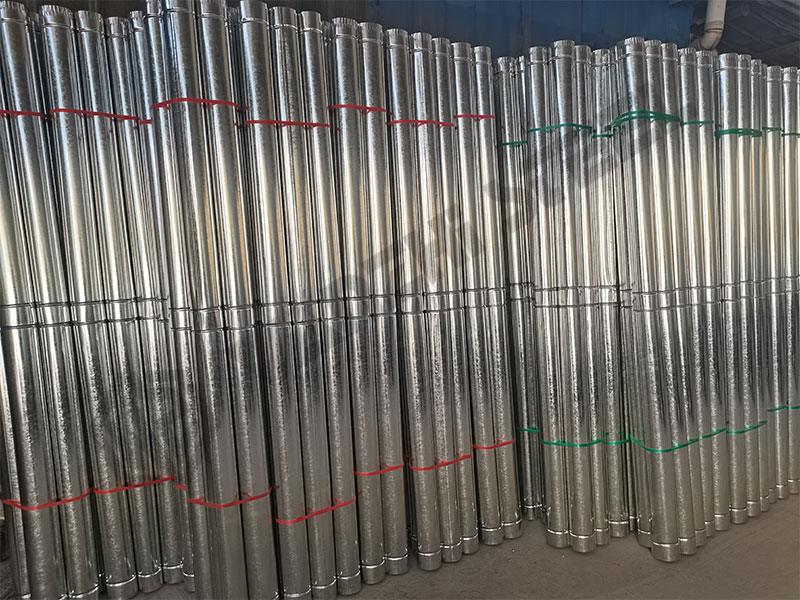

Wanzhi Group Galvanised Steel Tube Factory

Wanzhi Group has established a specialized galvanised steel tube production base in Boxing, Shandong, possessing full-chain capabilities of “pipe making – galvanizing – value-added processing – quality inspection.” We also supply raw materials including carbon steel, galvanized steel, stainless steel, and aluminum alloy.

Production Base

Our factory is located in Xingfu Town, Boxing County, Binzhou City, Shandong Province, close to Qingdao Port and Tianjin Port. The factory is equipped with continuous hot-dip galvanizing lines, high-frequency welded pipe production lines, seamless pipe customization lines, threading machines, flange welding machines, and internal coating equipment. We offer one-stop services for galvanized steel raw materials, production, pre-treatment, and custom processing.

Quality Control System

Wanzhi Factory is certified with ISO9001 Quality Management System and ISO14001 Environmental Management System. Our products comply with standards such as GB/T 3091, ASTM A53, EN 10255, etc. We provide material certificates for various products and support third-party quality inspections by institutions like BV and SGS. Please feel free to contact us if you need samples.

Delivery Capability & Service

Stock Supply: Standard specification hot-dip galvanized pipes are available from stock.

Custom Lead Time: Production cycle for special specifications is 5–45 days.

Export Support: We offer trade terms like CIF/FOB/EXW, handling customs declaration, inspection, and shipping bookings to ensure timely port arrival.

Technical Support: We provide specification selection advice, installation guidance, and respond to after-sales issues within 24 hours.

Galvanised Steel Tube Implementation Standards

| Standard Number | Scope of Application | Core Requirements |

| GB/T 3091-2015 | Hot-dip galvanized welded steel pipes for low-pressure fluid conveyance | Zinc coating weight ≥600 g/m², Hydrostatic test pressure ≤1.6 MPa, Wall thickness tolerance ≤±10% |

| GB/T 13793-2016 | Longitudinal electric resistance welded steel pipe (Base material standard) | Tensile strength ≥370 MPa, Yield strength ≥235 MPa, Weld quality Grade II |

| ASTM A53/A53M-22 | Welded and seamless steel pipe (including galvanized) | Hot-dip zinc coating thickness ≥85 μm, Pressure test strength ≤2.0 MPa |

| EN 10255:2004 | Hot-dip galvanized welded steel tubes for water service | Zinc coating weight ≥600 g/m², Salt spray test ≥500 hours without red rust |

| CJ/T 3022-1993 | Galvanized steel pipes for municipal gas | Zinc coating weight ≥800 g/m², Wall thickness increased by 20%, Sealing test qualified |

Galvanised Steel Tube vs. Stainless Steel Tube

| Comparison Aspect | Galvanised Steel Tube | Stainless Steel Tube |

| Core Cost | Low | High |

| Corrosion Resistance Principle | Sacrificial anode protection of zinc layer + physical barrier | Chromium forms a dense, self-healing oxide layer (passivation film) |

| Service Life | Long | Very Long |

| Mechanical Strength | High (carbon steel base) | High |

| Weldability | Welding damages the zinc coating, requiring post-treatment | Excellent, good weldability, and corrosion resistance can be restored after welding |

| Appearance | Silver-white with spangles or smooth silver/colored | Strong metallic luster, more aesthetically pleasing, suitable for decorative use |

| Hygiene | May leach zinc ions initially; suitable for water transport after long-term stabilization | Excellent, clean and sterile, the preferred choice for food and medical industries |

| Primary Applications | Building structures, fire protection, agricultural irrigation, municipal engineering, scaffolding | Food processing, medical devices, chemical industry, high-end architectural decoration, marine engineering |

| Selection Key | Limited budget, requiring long-term corrosion resistance in non-extreme corrosive environments | Sufficient budget, requiring extremely high hygiene standards or facing highly corrosive media |

Wanzhi Group is committed to providing premium metal materials for applications in various fields, including construction, industry, transportation, energy, and home appliances. In addition to galvanized steel tubes, we also offer galvanized coils, galvanized sheets, roofing panels, color-coated galvanized steel, and other corrosion-resistant materials. Please leave a message to receive free solutions and quotes.