VCM stands for Vinyl Clad Metal or Vinyl Laminated Metal, referring to vinyl-coated metal panels. PCM stands for Pre-Coated Metal, referring to pre-coated steel sheets. VCM and PCM are two common metal surface treatment methods. PCM has lower processing costs and is widely applied. VCM is a more advanced surface treatment technology developed from PCM, primarily used in high-end decorative applications.

Analysis: Differences Between VCM and PCM

| Aspect | VCM Sheet | PCM Sheet |

| Process | VCM stands for “laminating”. A plastic film is laminated onto the metal surface at high temperature. | PCM stands for “spray coating/roller coating”. Paint is applied onto the metal surface. |

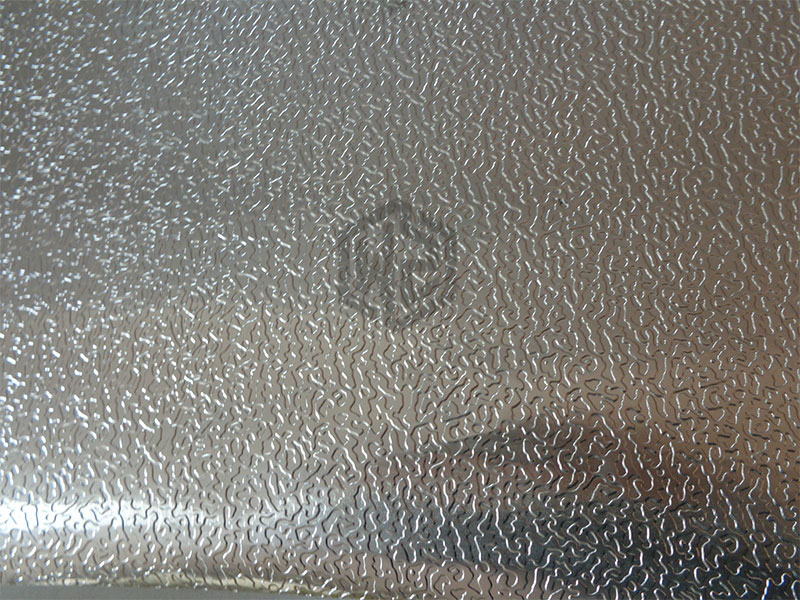

| Appearance | The color of VCM sheet is uniform and rich, with different gloss levels such as high gloss, matte, pearlescent, and metallic texture. | PCM sheet has uniform and rich colors, available in different gloss levels including high gloss, matte, pearlescent, and metallic texture. |

| Touch and Texture | The VCM film can achieve highly realistic three-dimensional textures (such as wood grain, leather grain) and special tactile sensations (such as skin-like feel), offering a richer decorative effect. | The PCM coating usually has a single texture, mostly smooth or with subtle orange-peel texture, and it is difficult to achieve complex three-dimensional textures. |

| Performance | The VCM film has excellent scratch resistance, fingerprint resistance, and stain resistance. | The PCM coating focuses on weather resistance, chemical corrosion resistance, and scratch resistance. |

| Cost | When achieving the same decorative effect, the cost of VCM is usually higher than that of PCM. | – |

| Efficiency | The VCM process is more complex, resulting in lower production efficiency compared to roller coating. | PCM is produced through roller coating, which has extremely high efficiency. |

Differences in VCM and PCM Applications

PCM Application Fields

- Construction: Roofing, wall cladding, and sandwich panels for factories and warehouses.

- Home Appliances: Outer casings (especially side panels and internal components) for refrigerators, air conditioners, washing machines, microwaves, etc.

- General Applications: Office partitions, furniture, and similar items.

VCM Application Fields

- Premium Home Appliances: Visible surfaces such as refrigerator doors, air conditioner panels, high-end washing machine panels, water heaters, etc., serving as “façade” materials.

- High-End Interior Decoration: Elevator cab interiors, cabinet doors, interior doors, premium office furniture, commercial space decorative panels.

Decision Guide

Building factory or warehouse roofs?

- Choose PCM (aluminum-zinc coated substrate + PVDF/SMP coating).

Making refrigerator sides and backs?

- Choose PCM (galvanized substrate + PE/HDP coating).

Refrigerator door panels or high-end cabinets?

- Consider VCM (for wood grain or leather effects).

Budget-conscious and practical?

- Choose PCM.

Generous budget and seeking luxury?

- Consider VCM.

Extremely high environmental standards?

- PET laminated panels.

Pre- coated Metal – Products

PET Laminated Sheet

PVC Laminated Sheet

PPGL Steel

PPGI Steel

PCM sheet offers cost-effectiveness, superior weather resistance, balanced performance, and broad applicability, while VCM sheet delivers exceptional decorative effects, premium tactile feel, and outstanding scratch and fingerprint resistance. Each plays a vital role in its respective field. Contact Wanzhi Group for further solutions and quotations.