DX51D+Z is a common hot-dip galvanized steel material commonly used in various construction and automotive industries. D stands for cold-formed steel, X51 is the performance grade, and +Z is the galvanizing process identifier, Wanzhi Group produces regular zinc layers from z30 to z350, with popular hot-dip galvanized specifications such as DX51D Z100, Z140, Z180, Z275.

Ingredients (chemical composition)

| Element | Content Range (wt%) | Function |

|---|---|---|

| Carbon (C) | ≤0.12 | Enhances ductility. |

| Manganese (Mn) | ≤0.60 | Increases strength. |

| Phosphorus (P) | ≤0.025 | Prevents cold brittleness. |

| Sulfur (S) | ≤0.025 | Improves machinability. |

| Aluminum (Al) | ≥0.020 | Improves coating adhesion. |

Performance Characteristics

| Property | Parameter Range |

|---|---|

| Tensile Strength | 270~350 MPa |

| Yield Strength | 140~240 MPa |

| Elongation (A80) | ≥22% (fracture elongation, suitable for deep drawing) |

| Galvanized Coating Weight | Common grades: Z60 (60g/m²), Z120 (120g/m²), Z180 (180g/m²), Z275 (275g/m²), etc. |

| Corrosion Resistance | Salt spray test: 100~500 hours without red rust. |

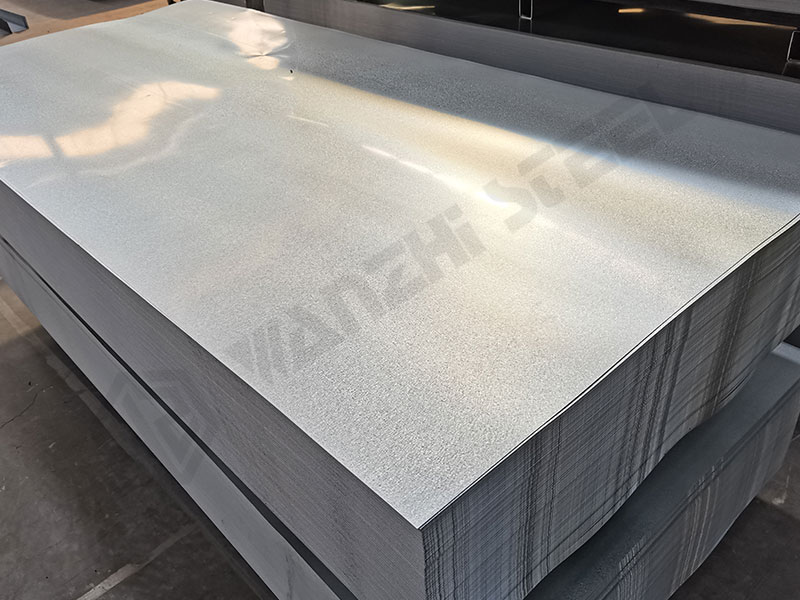

| Surface Quality | Zinc spangle surface (regular spangle, large spangle, small spangle) or smooth surface (no zinc flower, suitable for spraying). |

Materials and Specifications

| Parameter | Specification Range |

|---|---|

| Standard | EN 10346 Standard |

| Substrate Material | Low carbon steel (cold-rolled sheet) |

| Coating Type | Pure zinc coating (GI) or zinc-iron alloy coating (GA), typically pure zinc coating (GI) |

| Substrate Thickness | 0.15mm ~ 6.0mm |

| Zinc Coating Grade | Z60, Z80, Z100, Z120, Z150, Z180, Z200, Z275 (selected based on corrosion resistance requirements) |

| Standard Width | 600mm ~ 1500mm (customizable for slitting) |

Comparison of Similar Materials

DX51D+Z is the material designation in the European Standard EN 10346, and there are similar material grades in American, Japanese and Chinese standards, such as CS Type B, SGCC, DC51D+Z, etc.

| Standard/Grade | Corresponding Material |

|---|---|

| EN 10346 | DX52D+Z, DX53D+Z, DX54D+Z |

| ASTM A653 | CS Type B (US standard, similar tensile strength, zinc coating expressed in oz/ft²) |

| JIS G3302 | SGCC (Japanese galvanized steel sheet) |

| GB/T 2518 | DC51D+Z (Chinese standard, similar performance to DX51D) |

DX51D+Z , DX52D+Z、DX53D+Z、DX54D+Z

DX51D, DX52D, DX53D, DX54D are hot-dip galvanized steel for cold forming under EN 10346. The suffix “+Z” indicates the zinc-coated layer, and the numbers (51D~54D) represent the level of forming performance.

| Grade | Formability Level | Application Scenarios |

|---|---|---|

| DX51D+Z | Basic Forming | Simple bending, low deformation requirements (e.g., roofing, ventilation ducts) |

| DX52D+Z | Improved Forming | Medium complexity stamping (e.g., appliance housings, shelves) |

| DX53D+Z | Deep Drawing | Deep drawing, complex forming (e.g., automotive fuel tanks, washing machine drums) |

| DX54D+Z | Extra Deep Drawing | Extra deep drawing, precision forming (e.g., precision containers, complex structural parts) |

Chemical Composition Comparison (Typical, wt%)

| Element | DX51D+Z | DX52D+Z | DX53D+Z | DX54D+Z |

|---|---|---|---|---|

| Carbon (C) | ≤0.12 | ≤0.10 | ≤0.08 | ≤0.06 |

| Manganese (Mn) | ≤0.60 | ≤0.50 | ≤0.45 | ≤0.40 |

| Phosphorus (P) | ≤0.025 | ≤0.025 | ≤0.020 | ≤0.020 |

| Sulfur (S) | ≤0.025 | ≤0.025 | ≤0.020 | ≤0.020 |

| Aluminum (Al) | ≥0.020 | ≥0.020 | ≥0.020 | ≥0.020 |

Comparison of Mechanical Properties

| Parameter | DX51D+Z | DX52D+Z | DX53D+Z | DX54D+Z |

|---|---|---|---|---|

| Tensile Strength (MPa) | 270~350 | 270~340 | 270~330 | 260~320 |

| Yield Strength (MPa) | 140~240 | 140~220 | 120~200 | 120~180 |

| Elongation (A80, %) | ≥22% | ≥24% | ≥26% | ≥28% |

| Hardness (HRB) | 50~70 | 48~65 | 45~60 | 40~55 |

DX51D+Z, SGCC+Z, SGCD+Z

DX51D+Z, SGCC+Z, SGCD+Z are Wanzhi Group‘s popular galvanized steel grades, which are also commonly used in the home appliance industry, automotive parts, and construction.

Chemical Composition Comparison (wt%)

| Element | DX51D+Z (EN 10346) | SGCC+Z (JIS G3302) | SGCD+Z (JIS G3302) |

|---|---|---|---|

| Carbon (C) | ≤0.12 | ≤0.12 | ≤0.08 |

| Manganese (Mn) | ≤0.60 | ≤0.50 | ≤0.45 |

| Phosphorus (P) | ≤0.025 | ≤0.035 | ≤0.025 |

| Sulfur (S) | ≤0.025 | ≤0.035 | ≤0.025 |

| Aluminum (Al) | ≥0.020 | ≥0.020 | ≥0.020 |

Comparison of Mechanical Properties

| Parameter | DX51D+Z | SGCC+Z | SGCD+Z |

|---|---|---|---|

| Tensile Strength (MPa) | 270~350 | 270~410 | 270~380 |

| Yield Strength (MPa) | 140~240 | 140~240 | 120~220 |

| Elongation (A80, %) | ≥22% | ≥18% | ≥26% |

| Hardness (HRB) | 50~70 | 50~75 | 45~65 |

Comparison of Application Scenarios

| Grade | Typical Applications |

|---|---|

| DX51D+Z | – Building roofs/walls

– Household appliance enclosures – Ventilation ducts |

| SGCC+Z | – Light structural parts

– Furniture frames – Temporary barriers |

| SGCD+Z | – Car fuel tanks

– Washing machine drums – Deep-drawn containers |

DX51D+Z Surface Treatment Process

| Treatment Type | Process Details | Application Scenarios |

|---|---|---|

| Fingerprint-resistant (AF) | Water-based acrylic resin coating, thickness 0.5-1.5μm | Appliance panels, electronic enclosures (direct touch) |

| Phosphating (Parkerizing) | Zinc phosphate chemical conversion coating, film weight 2-4g/m² | Automotive parts requiring subsequent painting (enhances paint adhesion) |

| Self-lubricating Coating (Pre-lube) | Coating of ultra-thin lubrication layer (0.5-2g/m²) | High-precision stamping parts (reduces die wear, eliminates oiling step) |

| Electrostatic Oil Coating (Oiling) | Uniform rust-proof oil spraying (0.5-3g/m²) | Long-term sea shipping storage (moisture and oxidation protection) |

| Coating (Painting) | Coating with PE/SMP/PVDF/HDP/PU paints (primer 5-20μm, topcoat 10-40μm) | Building roofs/walls, appliance panels, whiteboards (corrosion resistance, aesthetics) |

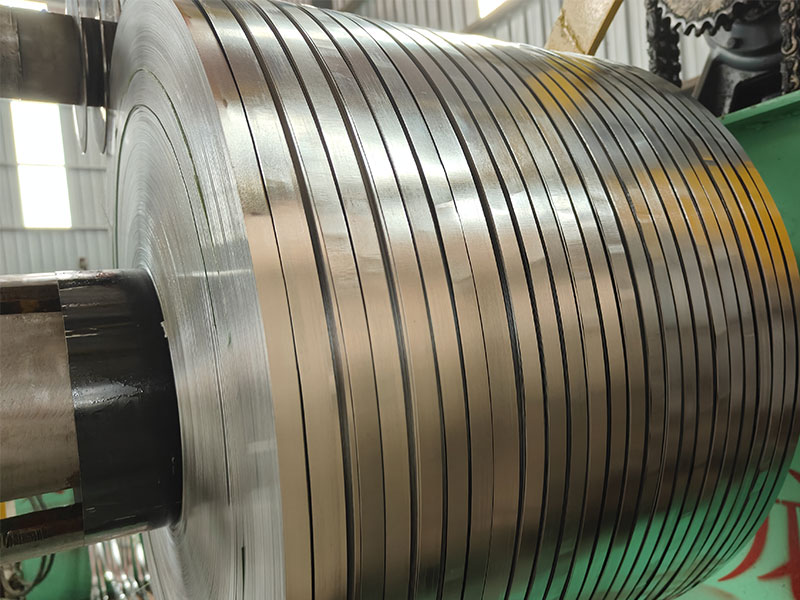

DX51D+Z Further Processing

DX51D+Z hot-dip galvanized steel has good workability. After stamping, forming, slitting and other processes, it can be made into corrugated galvanized steel sheets, roofing sheets, galvanized steel strips, galvanized perforated sheets, galvanized stamped sheets, galvanized profiles, galvanized wire mesh, galvanized pipes and other finished products.

- Stamping and molding

- Welding

- Cutting

- Composite lamination (architectural panels)

As a professional galvanized sheet manufacturer, we supply a wide range of grades of DX51D+Z hot-dipped galvanized steel and offer cost-effective steel solutions for construction, industry, agriculture and marine engineering, including galvanized steel, galvanized steel, color-coated steel, stainless steel and more. In the process of galvanized steel purchase, the matching of zinc layer weight and environment, surface treatment process is very important, if you are looking for experienced steel manufacturer, please contact us.