Galvanized and Painted Steel (also known as Pre-Painted Galvanized Steel or PPGI) is a corrosion-resistant steel product that combines the advantages of galvanizing and painting: Galvanizing – a zinc coating protects the steel from rust. Painted/Polymer Coating – A colored or protective coating enhances durability and aesthetics.

How is Galvanized and Painted Steel Made?

Step 1: Galvanization (Zinc Coating)

- Hot-Dip Galvanizing (HDG): Steel is dipped in molten zinc (450°C), forming a protective zinc coating (30-275 g/m²).

- Electro-Galvanizing (EG): A thinner zinc layer (10-50 g/m²) applied via electrolysis (used for precise coatings).

Step 2: Painting/Coating

- Primer (5-20µm): Enhances adhesion (epoxy resin common).

- Topcoat (10-40µm): Decorative/protective layer (options: polyester, PVDF, silicone-modified polyester).

- Backing Coat (optional): Extra protection on the reverse side.

Key Benefits of Galvanized and Painted Steel

| Feature | Galvanized Steel | Painted Galvanized Steel (PPGI) |

|---|---|---|

| Corrosion Resistance | Good (zinc protects) | Excellent (zinc + paint barrier) |

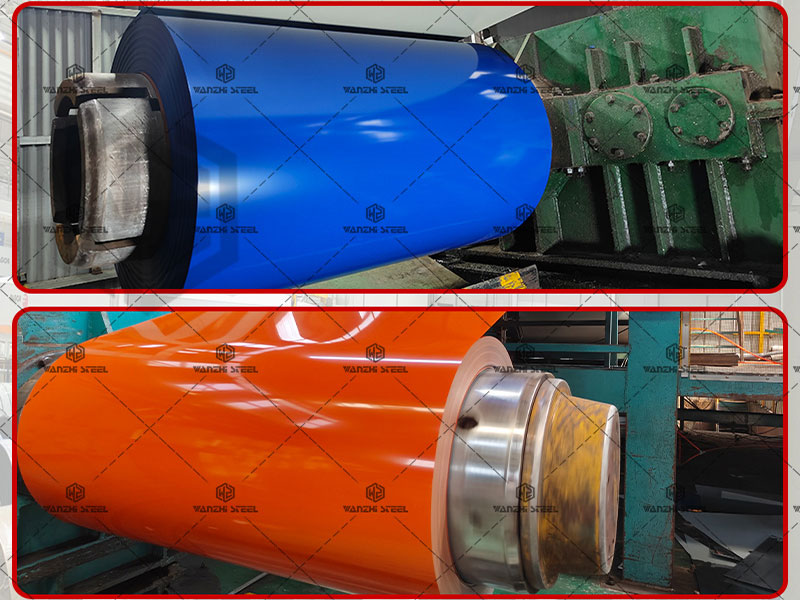

| Aesthetic Options | Metallic silver only | Any color/pattern (RAL, Pantone) |

| Lifespan | 15-30 years | 20-50 years (depends on coating) |

| Maintenance | Periodic inspection | Low maintenance (self-cleaning options) |

| Cost | Lower initial cost | Higher (but long-term savings) |

Common Applications

✅ Roofing & Wall Cladding – Used in factories, warehouses, and homes.

✅ Appliances – Refrigerators, washing machines, ovens.

✅ Automotive Parts – Body panels, chassis components.

✅ HVAC Ducts – Corrosion-resistant air ventilation systems.

✅ Agricultural Buildings – Resists fertilizer/chemical exposure.

Types of Paint Coatings on galvanized steel

| Coating Type | Properties | Best For |

|---|---|---|

| Polyester (PE) | Economical, good color retention | Indoor appliances, sheds |

| PVDF (Fluoropolymer) | Extreme weather resistance, UV-resistant | Coastal buildings, stadiums |

| SMP (Silicone-Modified Polyester) | Mid-range durability, better heat resistance | Industrial roofing, garages |

| PVC (Polyvinyl Chloride) | Flexible, impact-resistant, waterproof | Truck trailers, industrial flooring |

| PU (Polyurethane) | High abrasion resistance, chemical-resistant | Automotive parts, machinery panels |

| HDP (High-Durability Polyester) | Enhanced UV & corrosion protection | Architectural cladding, solar panels |

Galvanized steel vs. Painted Steel

Galvanized steel and painted steel are two common types of coated steel. Painted steel can be produced from coated steel such as galvanized steel/galvalume steel, and they are suitable for different application scenarios and can be purchased based on environmental conditions, aesthetic needs, and the level of protection required.

Galvanized Steel

Galvanized steel refers to steel that has been coated with a layer of zinc to prevent corrosion through the galvanizing process. The process of galvanizing is usually done in two ways: hot-dip galvanizing and electro-galvanizing.

Process

- Hot Dip Galvanizing: Steel is dipped into a bath of molten zinc to form a protective coating of zinc.

- Electro-galvanizing: Using electroplating, the zinc is uniformly applied to the surface of the steel.

Advantages of Galvanized Steel

- Corrosion Resistant: The zinc coating prevents rust and corrosion by effectively blocking moisture and oxygen from reaching the steel surface.

- Durable: Galvanized steel is very durable, especially high zinc-coated galvanized steel can be used for a long time in many harsh environments.

- Maintenance-free: Low maintenance costs make it more cost-effective for long-term use.

Common Uses

- Building Materials (e.g. roofing, framing)

- Automotive Components (e.g. body panels, exhaust systems)

- Outdoor Structures (e.g. fences, pylons)

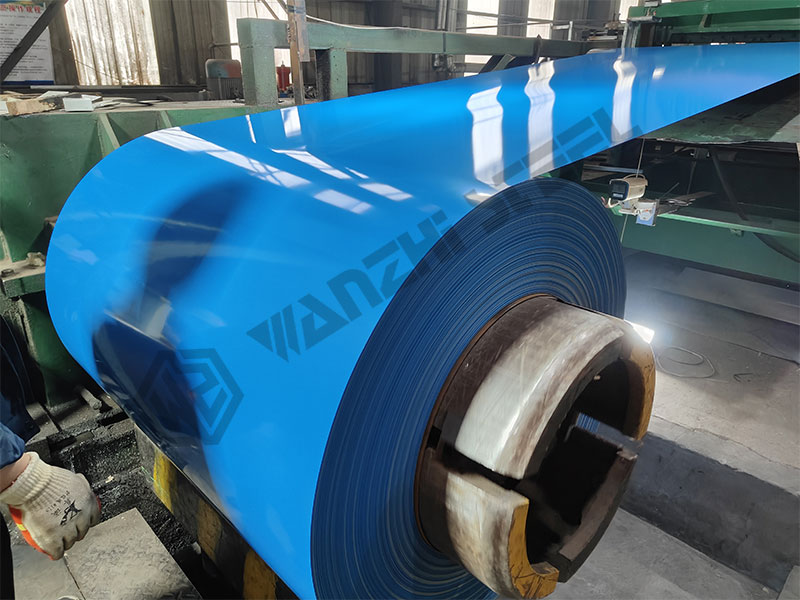

Painted Steel

Painted steel refers to the application of a layer of paint or a protective coating to the surface of a steel material. Paint is often used to improve the appearance of steel material and to provide an additional level of corrosion protection, and is commonly referred to as PPGI, or PPGL.

Painted Steel The steel process includes

- Surface Preparation: The surface of the steel is first cleaned and primed if necessary to ensure strong adhesion of the coating.

- Painting: Paint is applied by spraying, brushing, or roller coating.

- Curing: Curing by baking to harden the paint and make it adhere firmly to the substrate.

Advantages of Painted Steel

- Aesthetic Flexibility: Any color and finish can be selected as desired.

- Corrosion protection: Painted steel provides some protection against corrosion.

- Customization: Painted steel can be customized to meet specific design requirements or branding needs.

Common Uses

- Appliances (e.g. refrigerators, washing machines)

- Automotive bodywork (to provide color and protection)

- Architectural decorative elements (e.g. decorative panels, building facades)

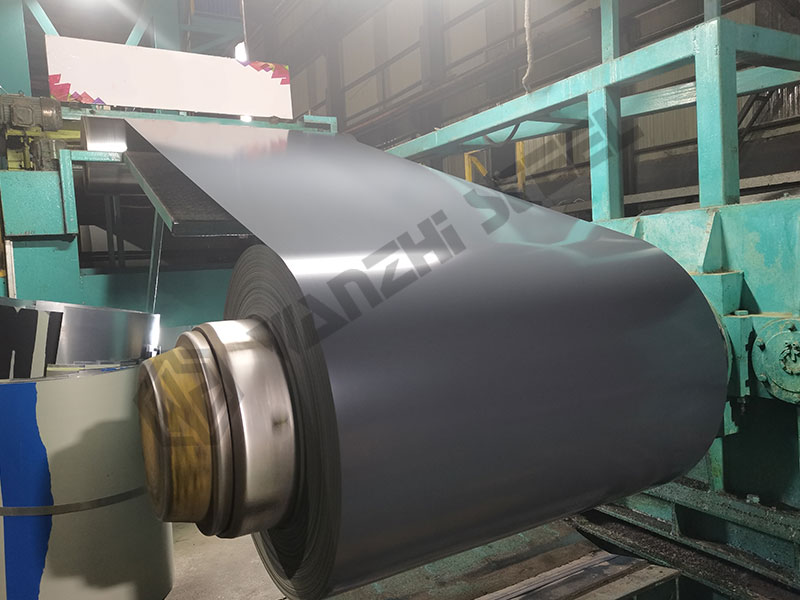

Galvanized and Painted Steel Supplier

Whether you are looking for galvanized steel, or galvanized and painted steel, Wanzhi Group can provide you with the most cost-effective solutions. As a professional supplier of galvanized and painted steel, we offer premium steel coil and sheet for architectural, automotive, and industrial applications under international standards such as ASTM, EN, JIS, ISO, etc.

Service

Full range of products: Products include, Cold Rolled Steel, Hot Rolled Steel, GI, GL, AL, ZAM, PPGI, PPGL, PPAL, Stainless Steel, and many more. Stainless steel, etc. We sell coils, plates, strips, tubes, wires, nets, profiles, etc.

Strong production capacity: 7 production lines, annual production capacity of 600,000 tons.

Fast delivery: 5–45 days.

Sufficient stock: We have raw materials in stock.

One-stop service: provide raw materials, customized solutions, production, further processing, transportation, and other services.

Standards & Quality Control

Galvanizing Standards: ASTM A653 (US), EN 10346 (EU), JIS G 3302 (Japan).

Paint Standards: ASTM D4145 (adhesion), ISO 12944 (corrosion resistance).

More Products

Galvanized and painted steel offers superior corrosion protection, design flexibility, and decorative and long-term durability, making it ideal for construction, automotive, and industrial uses, contact us for your project solution!