Prepainted Galvanized Steel is a composite material that is pre-coated with multiple layers of paint on the surface of galvanized steel and then baked and cured, combining the corrosion resistance of the galvanized layer with the decorative/functionality of the coating, commonly known as “Color Coated Steel” “PPGI steel (Pre-Painted Galvanized Iron) “ “pre-painted gi steel”. The combination of corrosion resistance and decorative functionality is achieved by applying paint by rollers to the surface of metal-coated steel galvanized steel.

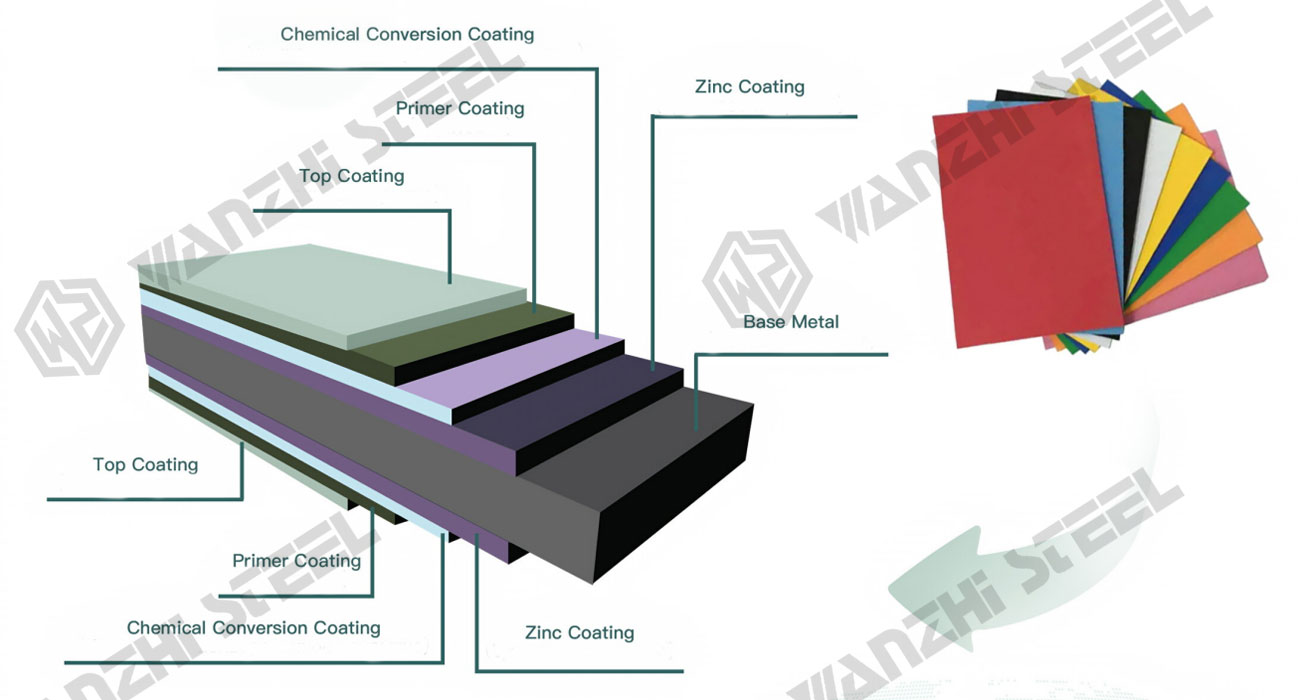

What is it Composed of?

Pre-painted Galvanized Steel is composed of cold rolled steel substrate + galvanized coating + chemical conversion layer + primer + topcoat, the topcoat can be coated with a special protective layer to enhance the corrosion resistance of the steel, durability, heat resistance, antimicrobial, decorative and other properties.

Structure

| Layer | Function and Material |

| Base Steel | SPCC/SPCD/SPCE/DC01-DC07/Q195, Q215, Q235 |

| Zinc Coating | Hot-dip pure zinc (GI) or galvanized zinc-aluminum (GL) (Zinc coating Z30-Z275 (30-275g/m²)) |

| Chromate | Chromate/phosphating treatment (enhances coating adhesion by 30%+) |

| Primer | Epoxy resin/polyurethane (Coating thickness 5-20μm, salt spray resistance >500h) |

| Topcoat | PE/HDP/PVDF/PVDF+Acrylic (Coating thickness 15-40μm, weather resistance 10-25 years) |

Process Flow

Degreasing → Galvanizing → Chromating → Roller coating primer → Top coating three coats and three baking → Lamination

Degreasing by alkaline washing: Removal of grease/dust.

- Galvanizing: The steel surface is coated with a uniform zinc protective layer through the hot dip galvanizing process.

- Chromating: Improve adhesion.

- Roller primer: Enhance adhesion + corrosion protection.

- Topcoat: Weather resistant + decorative.

- Coating: Improve scratch resistance/self-cleaning (coating can be selected according to the application).

Performance

Chemical properties (anticorrosion decisive point)

| Test Item | Ordinary Galvanized Steel | Pre-coated Galvanized Steel (PVDF Topcoat PPGI) |

| Salt Spray Test (Red Rust) | 1000 hours | 3000+ hours |

| QUV UV Aging | Chalky (12 months) | ΔE < 2 (60 months) |

| Acid & Alkali Resistance (5% HCl) | 24 hours corrosion | 240 hours with no change |

| Pollution Resistance (Ink) | Permanent residue | Can be wiped off with a damp cloth |

Mechanical properties (processability)

| Index | Test Standard | Typical Value of PPGI | Application Significance |

| Pencil Hardness | ASTM D3363 | 2H-3H (PVDF) | Resistance to transportation scratches |

| T-bend Flexibility | ASTM D4145 | 0T-2T | Suitable for severe bending |

| Impact Strength | ASTM D2794 | 9J (No peeling) | Resistance to hail/stone impacts |

| Cupping Test | ISO 1520 | 7.5mm (No cracks) | Deep drawing and forming capability |

Surface

Regular Surface: Plain painted galvanized steel without special treatment.

High Gloss Surface: Luster values usually between 80-100 GU, reflective.

Matte Surfaces: Luster values below 10 GU, less reflective, presenting a soft, non-glossy effect.

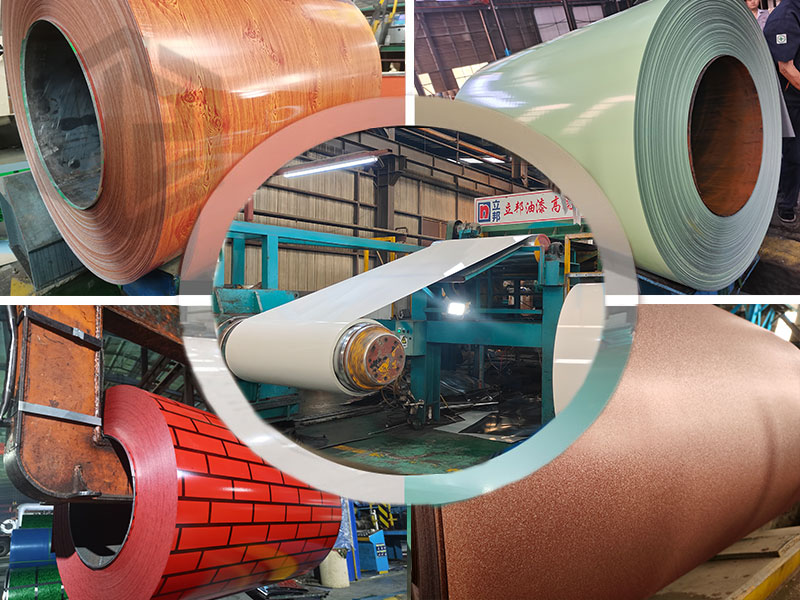

Textured Surfaces: Metal texture, orange peel texture, leather texture, dimpled texture, etc.

Printed pattern surfaces: woodgrain-like, brick-like, floral, geometric, and customized patterns.

Functional surfaces: fingerprint resistant (contact angle >110°), anti-bacterial coating (anti-bacterial rate >99.9%), thermal insulation coating (surface cooling of 8-12℃), self-repairing coating (self-healing of scratches in 24 hours).

Why Prepainted Galvanized Steel Beats Plain Galvanized Steel?

Galvanized and prepainted galvanized steel are two common corrosion protection treatments for metals. While galvanized focuses on corrosion protection, color coated galvanized offers a wide range of colors and finishes along with corrosion protection. In addition, painted galvanized is a painted galvanized steel substrate that combines the advantages of both galvanized and painted, making painted galvanized steel a better choice for budget-minded applications where appearance is important.

| Dimension | Ordinary Galvanized Steel | Prepainted Galvanized Steel |

| Corrosion Life | 5-15 years (dependent on zinc layer thickness; thicker zinc layer increases lifespan) | 15-30 years (dual protection with zinc layer + coating) |

| Decorative Freedom | Monotonous silver-gray color | Customizable colors based on color charts and samples, with various surface effects like wood grain, metal, stone, printing, etc. |

| Function Expansion | None | Optional antibacterial/self-cleaning/insulation coatings |

| Unit Price | $600-800/ton | $700-1200/ton |

Where to Use Prepainted Galvanized Steel ?

Pre-painted galvanized steel plays an important role in any application where superior corrosion resistance, strength and aesthetics are required. Its superior durability, corrosion resistance and aesthetics have made it an essential metal for modern manufacturing applications such as construction, automotive, appliance and signage.

Building Construction

- PPGI PPGL Roofing Sheets: Pre-painted galvanized steel roofing sheets for residential, commercial and industrial buildings are used in a wide range of applications for a variety of colors, patterns, sheet shapes, weather resistance and long life. In addition, tropical roofing panels can be coated with infrared-reflective ceramic particles for interior cooling.

- Pre-painted galvanized steel facade panels: PPGI PPGL facade cladding, with its high strength and structural support, not only provides a clean and modern look, but also provides effective protection against the elements.

- Pre-Painted Ceiling Panels: Excellent durability and impact resistance, light weight, easy to install, good sound insulation are the painted galvanized ceiling/ceiling panels are used in a wide range of interior designs that are both aesthetically pleasing and practical.

Transportation

- Trains, trucks and buses: Pre-painted galvanized steel has high strength, abrasion resistance and can be stamped/printed for exterior body panels, non-slip floors, etc., for a wide range of vehicles.

- Automotive: Pre-painted galvanized steel is used for body components such as doors, hoods and trunks. High-end automotive components can also be made from self-repairing coated steels, whose durability, corrosion resistance and paintability allow them to remain stable when exposed to weather and wear.

Household appliances

- Refrigerators and washing machines: Fingerprint-resistant painted and matted sheets that resist corrosion while providing an attractive, fingerprint-resistant surface are popular enclosure metals for household appliances, including refrigerators, washing machines and air conditioners.

- Kitchen appliances: Other kitchen appliances such as microwaves and ovens are also made from highly weatherable, heat-resistant coated pre-painted galvanized steel.

Energy & Power

- Electrical Equipment Enclosures: The use of color-coated galvanized steel in electrical installations such as switchboards, distribution panels and cabinets protects against electrical hazards and environmental conditions.

- Solar Panel Frames: Pre-painted galvanized steel is commonly used in solar panel frames due to its high strength, light weight and weather resistance.

Agriculture & Storage

- Agricultural Machinery: Pre-painted galvanized steel is used in the manufacture of agricultural machinery for its corrosion resistance in outdoor agricultural environments to extend the life of the machinery.

- Greenhouses: For applications such as large-span structures, piping systems, etc., PPGI pre-painted galvanized steel can withstand high humidity and resist environmental factors such as UV rays and acid rain, while providing high strength and good resistance to bending.

- Sheds and Storage Units: For making outdoor storage units, garden sheds and other similar structures, PPGI pre-painted galvanized steel is popular for its high strength, ease of maintenance and corrosion resistance.

Other Industries

- Furniture: The scratch and corrosion resistant properties of coated steel are often used in the manufacture of modern furniture such as tables, chairs and storage units. The durable coating gives it.

- Equipment: glossy PPGI steel offers durability and a glossy finish and is also used in the production of products such as bicycles and sporting goods.

- Outdoor signage: colored and printed prepainted galvanized steel is commonly used for street signs, billboards and other outdoor signage improves visibility.

- Writing Boards: PPGI PPGL Steel is clean, corrosion resistant, and makes writing boards that can be written on and erased over and over again.

How to Choose Prepainted Galvanized Steel?

Before buying prepainted galvanized steel, we only need to remember a slogan “corrosion environment set the zinc layer, design life set the coating, aesthetic needs set the color, cost control set the thickness” will be able to buy the most cost-effective steel!

Base plate selection (anti-corrosion foundation)

Base plate is also galvanized steel determines the corrosion resistance of the steel life and applicable environmental conditions.

- General corrosive environments: rural, urban, and other applications can choose a low zinc layer of galvanized steel as a substrate, that is, the zinc layer thickness is less than z120, less than 120 grams of zinc per square meter.

- Medium corrosive environments: Commonly found in chemical zones, etc.. Highly zinc coated galvanized steel, e.g. Z275, can be selected as a substrate.

- Highly corrosive environments: marine areas, can choose zinc-aluminized, AZ150+, as a substrate.

Coating selection (functional core)

The coating material determines not only the service life but also the cost and the specific application environment.

| Coating Type | Weather Resistance (Years) | Cost | Applicable Scenarios |

| PE | 7-10 years | Low | Inland dry areas/indoor use |

| HDP | 10-15 years | Medium | Rainy cities/light industrial areas |

| PVDF | 20-25 years | High | Coastal areas/heavy pollution areas |

| PVDF + Acrylic | 25+ years | Highest | Landmark buildings/extreme climates |

Colors

The colors of Prepainted steel PPGI PPGL PPAL and other color coated steel can be tinted on demand.

- For indoor applications, light colors (e.g. white, beige, light gray, etc.) enhance the brightness and comfort of the space.

- For outdoor billboards, bright colors (yellow, orange, pink, white, etc.) are more eye-catching and serve as reminders and warnings.

- For outdoor architecture, darker colors (e.g. dark blue, dark green, etc.) resist UV rays and hide scratches and stains.

- For general applications, standard colors include red, blue, gray, green, etc.

Thicknesses

Wanzhi group produces prepianted galvanized steel in thicknesses ranging from 0.12 to 1.5 mm. The thickness of the sheet determines the cost. Thinner sheets are usually less costly and less durable; thicker sheets are more costly and more durable.

- For large buildings or load-bearing structures, choose PPGI PPGL steel sheets of 0.6mm and above.

- For decorative or covering purposes, choose PPGI PPGL coils such as 0.3mm or 0.4mm.

- Choose thinner PPGI PPGL sheets of 0.2mm to 0.4mm for complex processing applications.

Film Thickness Verification

- Tools: Magnetic thickness gauge for substrate inspection, eddy current thickness gauge for coating inspection.

- Standard: Top coat ≥15μm, primer ≥5μm (Standard is determined by demand.)

Certifications

- ISO 9001 (Quality Management)

- ISO 14001 (environmentally friendly production)

- ASTM A755 / EN 10169 (performance standards)

If you have other questions about Prepainted galvanized steel, please feel free to contact us, Wanzhi Group is a factory supplier of prepainted steel from China, our prepainted steel coils and sheets have been exported to more than 100 countries all over the world, we have rich experience in production and customization. We have rich experience in production and customization. If you are interested in other pre-painted steel coils, please feel free to contact us!