PPGI sandwich panel is also called color-coated anticorrosive insulation board, because of the performance of thermal insulation, fireproofing, sound insulation, etc., commonly used in construction projects for walls and roofs, Wanzhi Group popular PPGI panels are, PPGI pu sandwich panel, PPGI EPS sandwich panel, PPGI Rock Wool panel, Glass Wool/XPS/PF sandwich panels, etc.

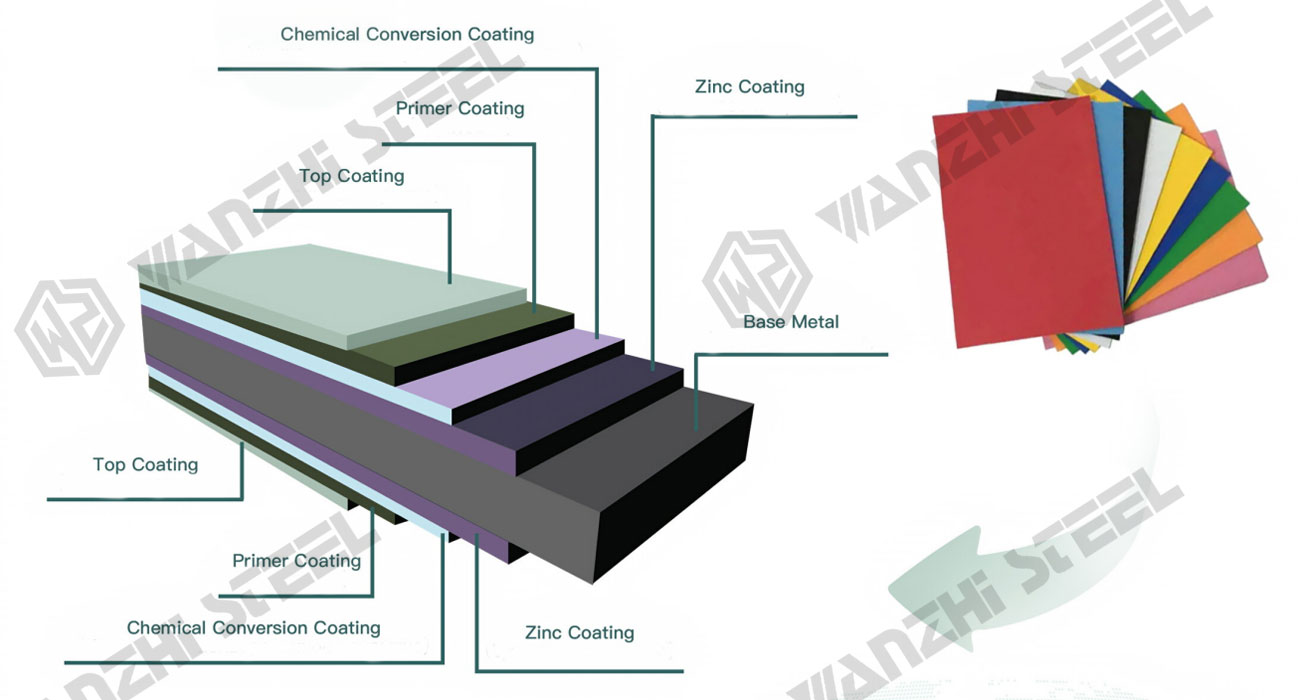

Structure of PPGI Sandwich Panel

A PPGI sandwich panel consists of an outer layer of PPGI steel and an intermediate core material. Depending on the application scenario, you can customize the outer layer of steel, including color, pattern, paint, varnish, board shape, etc., and the core material with different properties.

Common Core Material Types

Polyurethane (PU)

The use of polyurethane as a core material for sandwich panels provides optimal thermal insulation for buildings. In addition, PU is lightweight, strong, and can be used for a wide range of applications.

Characteristics

Excellent thermal insulation (low thermal conductivity, approx. 0.022-0.028 W/m-K).

Higher density (30-50 kg/m³) and good strength to withstand larger loads.

Fire rating is generally B1 (flame retardant).

Applications

Cold storage, thermostatic workshops, high-end buildings.

Polystyrene (EPS)

Polystyrene sandwich panels are low-cost, economical, lightweight, and easy to install. However, they are generally not durable and are not suitable for long-term use in construction projects.

Properties

Good thermal insulation (thermal conductivity about 0.035-0.045 W/m-K).

Low density (15-30 kg/m³), lowest cost.

Fire rating is generally B2 (combustible).

Uses

Temporary buildings, general factory buildings, warehouses.

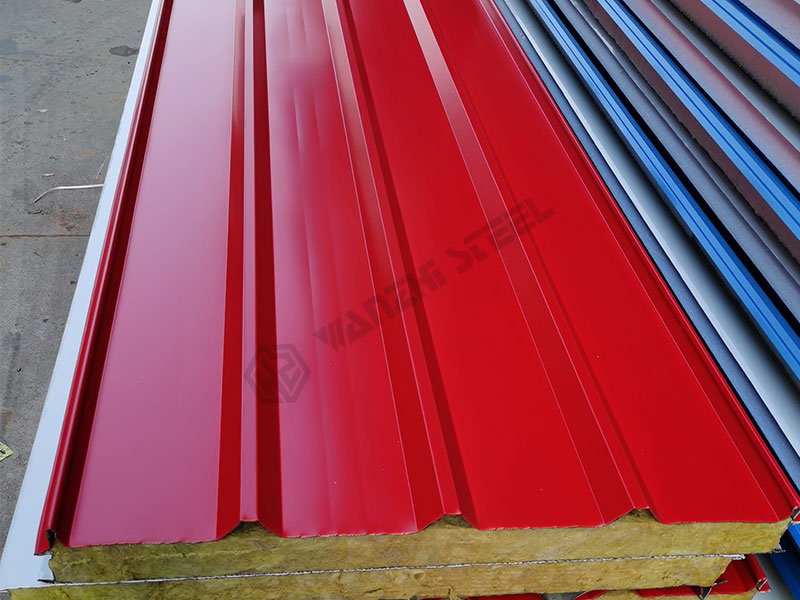

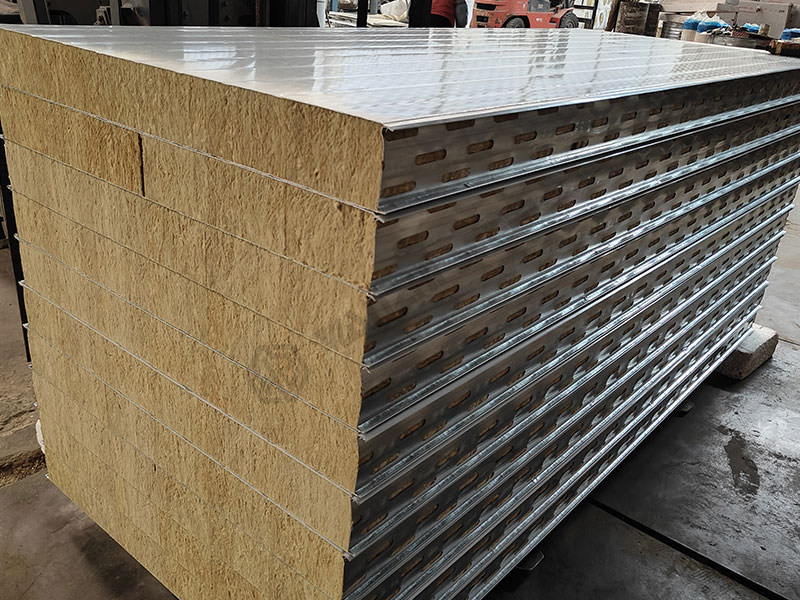

Rock Wool

Cotton rock color coated sandwich panel, with moderate cost, good fire resistance, and environmental protection, is one of the popular sandwich panels.

Performance

Medium thermal insulation performance (thermal conductivity of about 0.040-0.045 W/m-K).

Higher density (80-150 kg/m³), excellent fireproof performance (Class A non-combustible).

Good sound insulation, and high temperature resistance (melting point >1000°C).

Applications

Places with high fire protection requirements (e.g. chemical plants, power stations, hospitals).

Glass Wool

The performance of glass-faced sandwich panels and rock wool sandwich panels is similar, it is lighter but less environmentally friendly.

Performance

Insulation performance is similar to rock wool (thermal conductivity of about 0.035-0.045 W/m-K).

Lower density (10-48 kg/m³), fireproof grade A.

Soft and easy to cut, but easy to produce dust.

Applications

Light construction, air-conditioning pipe insulation.

Extruded Polystyrene (XPS)

XPS PPGI sandwich panels are always suitable for roofing and walling in humid environments, with excellent resistance to compression and moisture, strength, and thermal insulation.

Properties

Better thermal insulation than EPS (thermal conductivity around 0.030-0.035 W/m-K).

Higher density (25-45 kg/m³), high compressive strength, good moisture resistance.

Fireproof grade B1-B2.

Applications

Applicable scenes: basement, floor insulation, cold chain logistics.

Phenolic resin (PF)

Phenolic resin as the core material made of color-coated sandwich panel insulation, fire prevention, and sound insulation effect is excellent, but the price is expensive, suitable for high-end fireproof building use.

Properties

Good thermal insulation performance (thermal conductivity of about 0.020-0.025 W/m-K).

Fire class A, high temperature resistant, no toxic smoke emission.

High density (40-60 kg/m³), high cost.

Applications

High-end fire-resistant buildings, aerospace field.

Comparison of the Performance of Six Sandwich Panel Core Materials

| Material | Thermal insulation | Fire resistance | Strength | Applicable scenes |

| PU | Excellent | General | Good | General Cold storage, constant temperature workshop |

| EPS | Average | Average | Average | Temporary buildings, general workshops |

| Rock wool | Excellent | Normal | Medium | Excellent Chemical plants, power stations |

| Glass wool | Good | Good | Medium | Lightweight construction, air conditioning ducts |

| XPS | Good | Normal | Food | Basement, cold chain logistics |

| Phenolic | Excellent | Excellent | Food | High-end fireproof construction |

Recommendations for Core Material Selection

The choice of core material has a direct impact on the thermal, acoustic, and fire performance of sandwich panels. Choosing the right core material according to the needs, the application, and the climatic conditions will not only reduce the cost of the project but also prolong the service life of the panels.

Select according to the priority of needs

Insulation performance: PU, phenolic resin, followed by XPS.

Fireproof performance: rock wool, glass wool, phenolic resin.

Cost control: EPS, XPS.

Environmental requirements: rock wool, phenolic resin.

Selection by application scenarios

Industrial plant/warehouse: EPS (economic) or PU (high performance).

Cold storage/thermal workshop: PU or XPS (moisture-proof).

Chemical plant/hospital: Rock wool (Class A fireproof).

Basement/floor: XPS (pressure and moisture resistant).

High-end building: Phenolic resin (optimal comprehensive performance).

Selection by climate conditions

Humid areas: XPS or PU

High-temperature areas: Rock wool or Phenolic

Customized PPGI Sandwich Panels?

How to customize PPGI sandwich panels after choosing the core material? Wanzhi Group offers a full range of customized panels, not only with different core materials but also with a choice of material, color, pattern, surface treatment, etc. The panels are made of PPGI, PPS, PU, RPU, PPS ,or Phenolic.

- Material: PPGI, PPGL, Color Aluminum, etc.

- Color: RAL color card, or other color cards.

- Paint: PE, SMP, PVDF, HDP, PU, etc.

- Pattern: wood, flower, brick, marble, grass, or other customized patterns.

- Sheet type: corrugated, ribbed, trapezoidal, flat, etc.

- Surface: glossy, Matt, wrinkled, 3D, etc.

Factory Supplier Recommendation

China is the main producer of PPGI steel, with mature color-coated steel production and processing technology, importing PPGI sandwich panels from China with a wide range of competitive prices! Wanzhi Group is a steel supplier from China, our factory Wanzhi Steel Factory is located in Binzhou City, Shandong Province, China, with ISO9001, ISO14001, and other certificates. Our factory offers customized service of sandwich panels with different materials, welcome to contact us.

Frequently Asked Questions

Q1: Which is more suitable for a high-temperature environment, PU or rock wool?

A: Rock wool is better for high-temperature resistance, suitable for high-temperature workshops or places with high fire protection requirements.

Q2: How long can EPS sandwich panel last?

A: EPS in a dry environment life of about 10-15 years.

Q3: How to judge the quality of core material?

A: Check the density uniformity, fire test report, environmental protection certification, and test the thermal conductivity.

Q4: How to install PPGI sandwich panel?

A: PPGI panel usually adopts bolt or snap type installation, installation is relatively simple.

Q5: How much is the price of PPGI panel?

A: The price of PPGI panel is determined by the type of material, thickness, surface coating, and quantity, for example, if the price of a rock wool PPGI panel is higher than that of polystyrene sandwich panel, leave a message to tell us the style and material of the panel you need, and we will provide you with a free quote.

Q6: Can you provide samples?

A: We can provide samples of all regular steel.

Q7: Can I ask a third-party organization to inspect the goods after production?

A: Yes, we support SGS, BV, and other third-party organizations to come to our factory for inspection.

Products

The selection of core material for PPGI sandwich panel needs to consider many factors such as thermal insulation, fire protection, cost, environmental protection and so on. As a professional coated steel factory, Wanzhi Group can provide customized sandwich panel solutions with various core materials, welcome to contact us for more information!