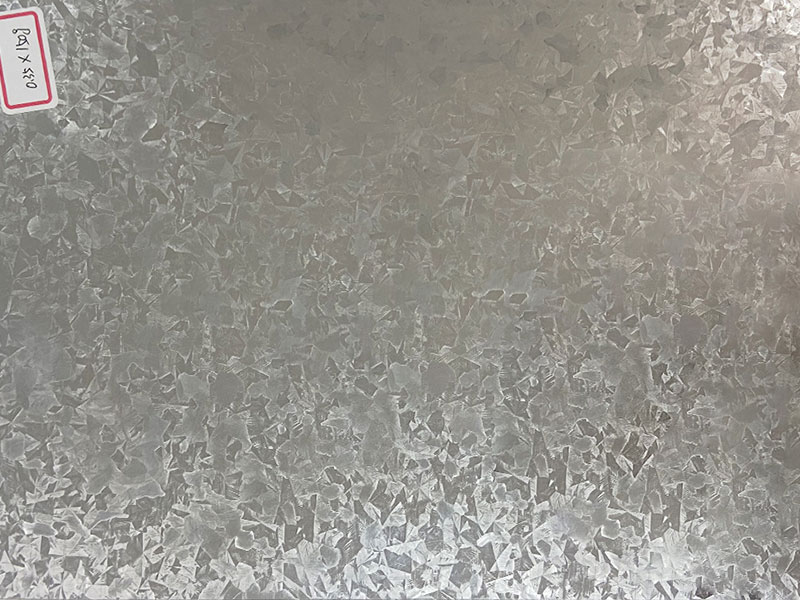

Galvanized steel is protected against rust by a surface coating that insulates it from air, water, etc. In normal environments, galvanized steel with a high zinc coating has a lifespan of 20–50 years. However, surface rusting often occurs due to humid storage environments, thin zinc coatings, etc. Effective surface preparation and preventive measures are essential. Effective surface treatment and preventive measures will reduce our operating costs.

How to Deal with Red Rust on Galvanized Steel Surface?

Red rust on galvanized steel is due to oxidation of the steel base after the destruction of the galvanized layer of corrosion phenomenon, once found on the surface of galvanized steel rust, promptly to prevent the expansion of the corrosion area. Common red rust treatment methods are mechanical rust removal, chemical rust removal, sandblasting, and household convenience rust removal measures.

How to Avoid Galvanized Steel Rust?

Recommended Zinc Coating for Different Use Environments

To maintain the performance of galvanized steel for a long time, we must first determine the use environment, and then choose the appropriate zinc layer thickness according to the application scenario. For general environments, industrial areas, and marine environments, we have the following suggestions.

| Use | Recommended |

|---|---|

| Indoor uses | Z10 or Z12 (100 g/㎡or 120 g/㎡) |

| Suburban area | Z20 and painted (200 g/㎡) |

| Urban or industrial area | Z27 (270 g/㎡) or G90 (American Standard) and painted |

| Coastal area | Thicker than Z27 (270 g/㎡) or G90 (American Standard) and painted |

| Stamping or deep drawing applications | Thinner than Z27 (270 g/㎡) or G90 (American Standard) to avoid coating peeling off after stamping |

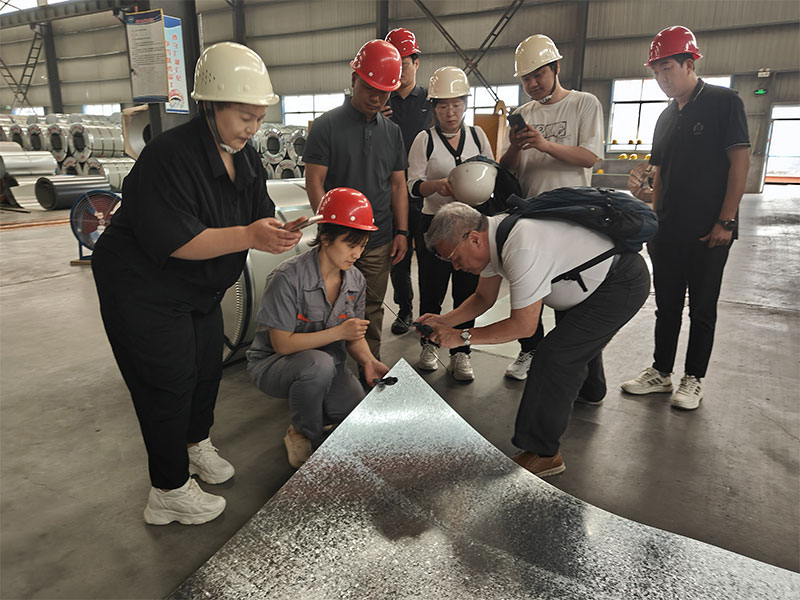

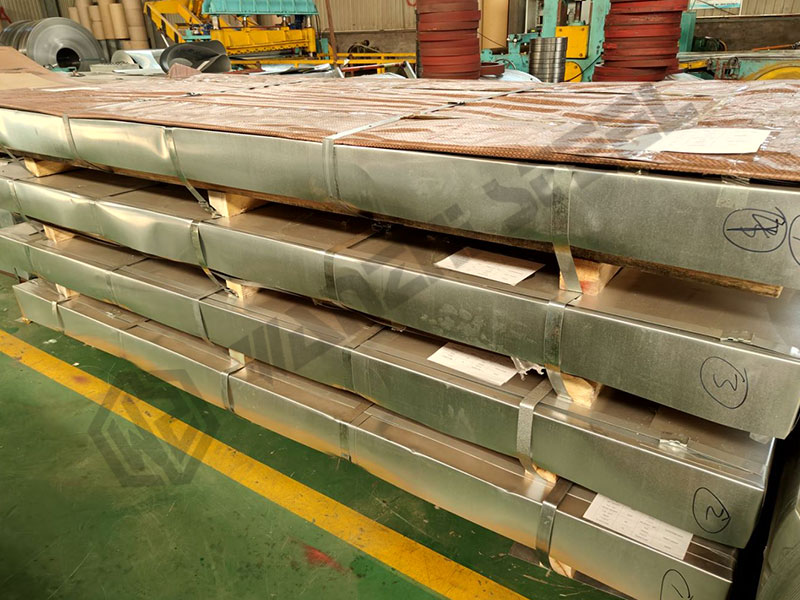

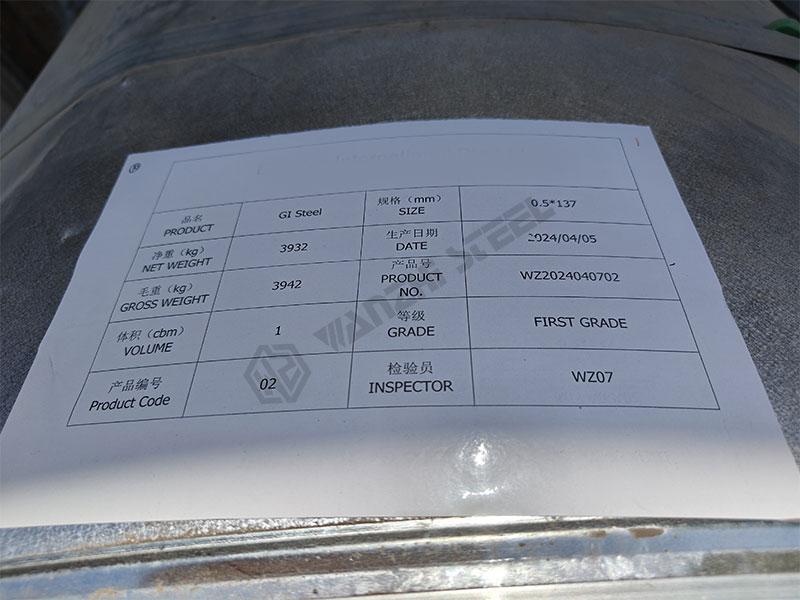

Where to Buy High-Quality Galvanized Steel?

If you are looking for a high-quality galvanized steel supplier! Then Wanzhi will be your best choice. First, we have our production line, and we can customize steel with different specifications and zinc layer thickness. Secondly, we have a supply chain management system, which not only has raw material inventory but also can save costs from all links and provide the most competitive prices. Finally, we have served more than 100 countries including Malaysia, Saudi Arabia, UAE, Belarus, France, Colombia, Chile, Azerbaijan, Libya, Indonesia, etc.