PPGI Steel Coil, fully known as pre-painted galvanized steel coil and abbreviated as PPGI coil, is a composite metal material that combines the corrosion resistance of galvanized steel with the aesthetic appeal of a pre-applied paint coating. It is widely used in construction, home appliances, machinery, education, advertising, energy, decoration, and other fields.

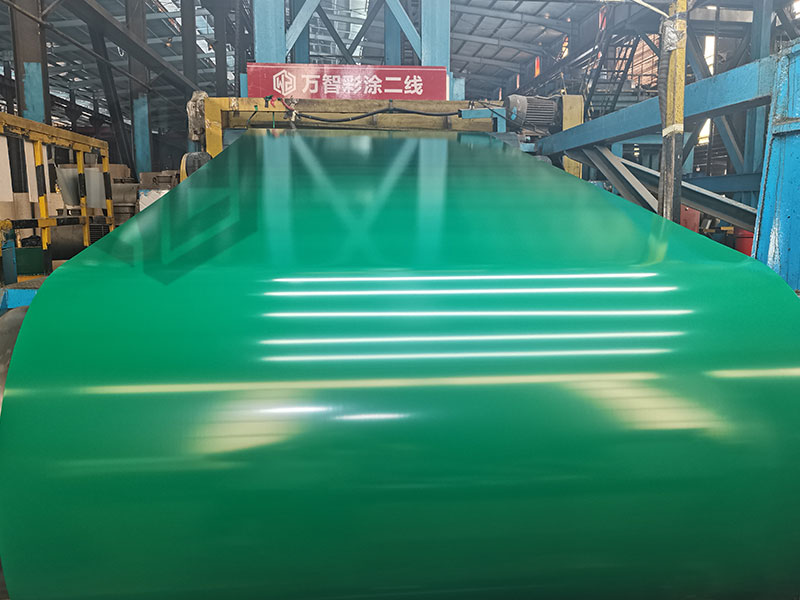

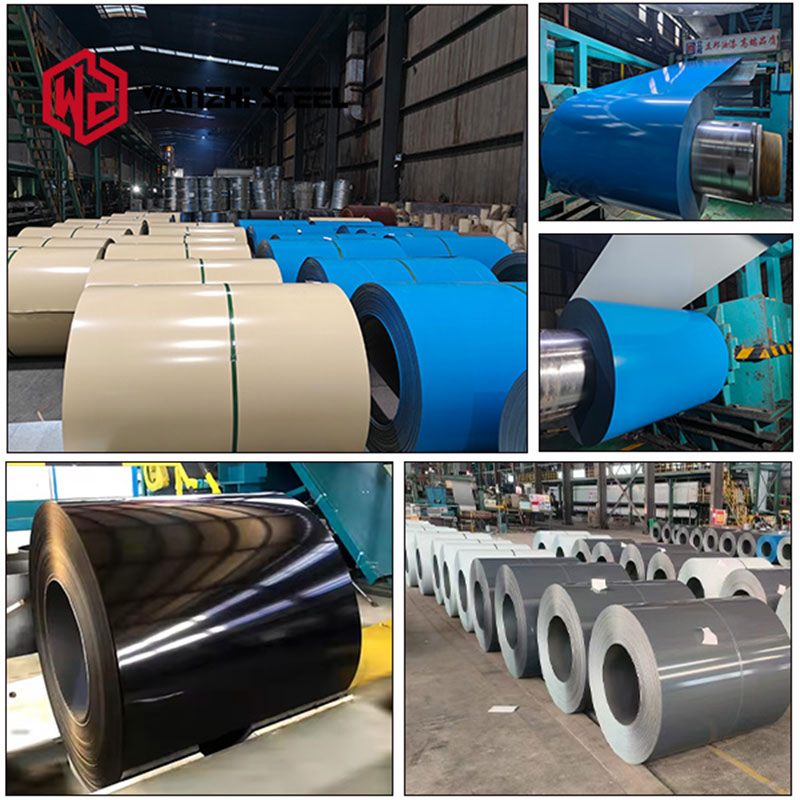

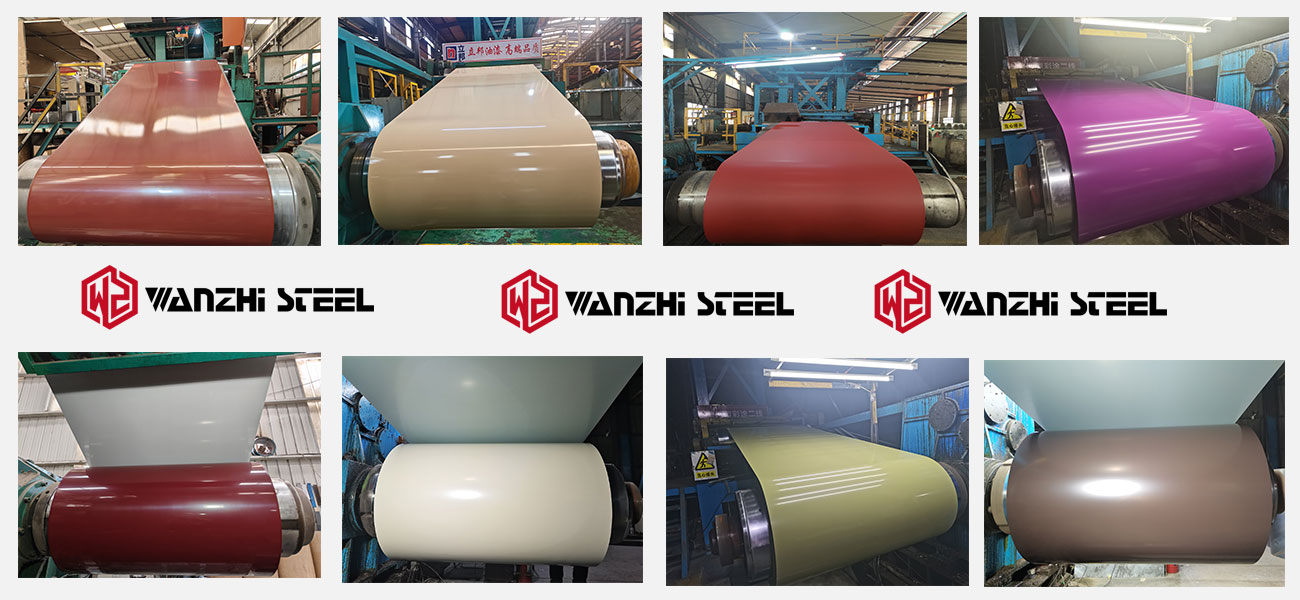

PPGI Steel Coil – Color

Solid colors represent the most classic and widely used category of PPGI color-coated coils, and are also the most popular type of color-coated steel products from Wanzhi Group. Their uniform and vibrant hues meet the needs of the vast majority of architectural and industrial applications. They are extensively used in home appliance panels (such as refrigerators and washing machines), interior decoration, high-end office furniture, modern building curtain walls, and interior ceiling partitions.

- Popular Colors: RAL5002, RAL5005, RAL9003, RAL9016, RAL9002, RAL6005, RAL3003, RAL3005, RAL5002, RAL6016, RAL6018, RAL6019, RAL8004, RAL8017, RAL6005, RAL8017, RAL8019, etc.

- High-gloss solid colors PPGI: High surface gloss (typically ≥70%), vibrant and rich hues, strong reflectivity, aesthetically pleasing and easy to clean.

- Matte Solid Colors PPGI: Low surface gloss (typically ≤30%), featuring soft, elegant hues and a premium texture. Effectively conceals minor scratches and shipping wear while providing glare resistance.

- Satin/Semi-Matte PPGI: Gloss level between high-gloss and matte (approximately 30%-50%), offering balanced color expression and scratch resistance. An ideal choice for harmonizing aesthetics with practicality.

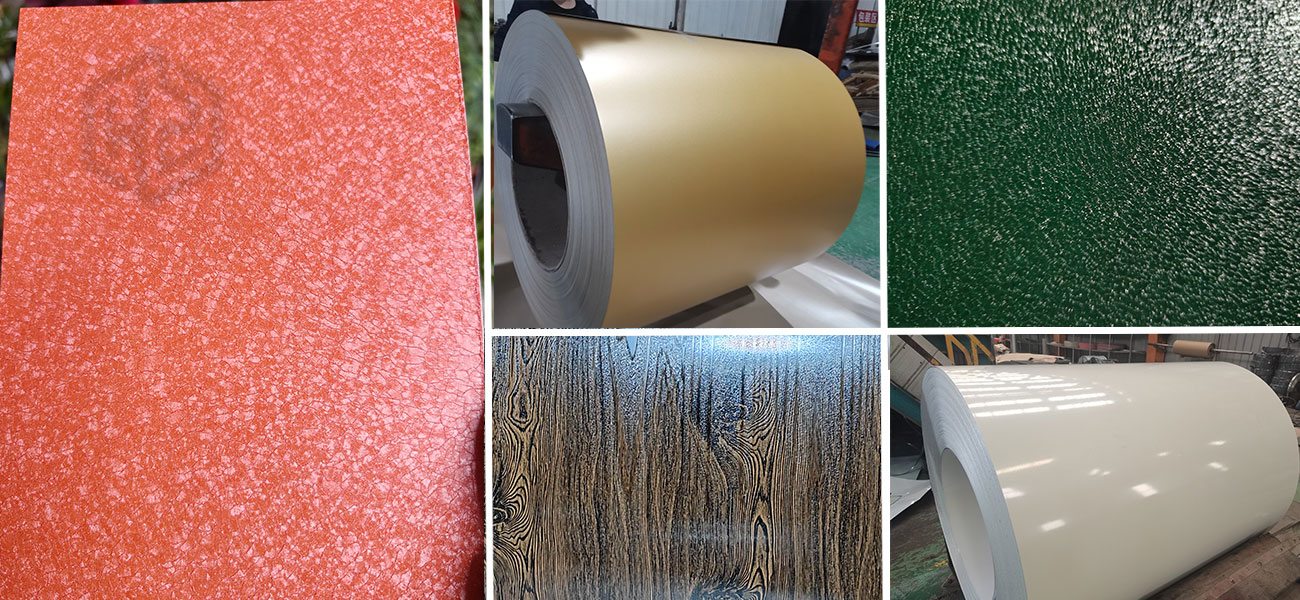

PPGI Steel Coil – Textured

Textured PPGI Steel Coil features a unique three-dimensional tactile and visual effect achieved by incorporating special pigments into the coating or applying mechanical embossing to create a raised pattern on the coil surface. This texture effectively conceals scratches, stains, and imperfections. Widely used in building facades and walls, home appliances and enclosures, interior decoration, furniture panels, storefronts/elevator cabins, accent walls, commercial space decoration, high-end appliance panels, interior furnishings, and furniture.

- Orange Peel Texture PPGI: The most common pattern, resembling orange peel, effectively conceals scratches from processing and installation while offering excellent scratch resistance.

- Wood Grain PPGI: Realistically simulates the texture and feel of wood, delivering a natural visual effect while retaining the durability of steel.

- Stone Grain PPGI: Mimics the granular texture of natural marble or granite, creating a steady, sophisticated industrial aesthetic or premium feel.

- Leather Grain PPGI: Produces a soft, leather-like tactile sensation and visually elevated appearance.

PPGI Steel Coil – Printed

Printed PPGI Steel Coil is a color-coated product that builds upon PPGI coil by applying various patterns to its surface through processes like transfer printing and roller coating. It combines corrosion resistance with decorative appeal, finding widespread use in high-end construction, home appliances, advertising, and other fields. It is primarily employed in areas emphasizing individuality and brand recognition, such as interior decoration, brand boutiques, exhibitions, and creative spaces.

- Printed color-coated coils achieve high levels of personalization and artistic expression by directly printing diverse patterns and images onto steel coil surfaces via digital printing or roller coating techniques.

- Custom Patterns PPGI: Any design—including corporate logos, brand graphics, or artistic paintings—can be directly printed onto the panels.

- Natural Scenery PPGI: Floral, insect, aquatic, botanical, or other regionally distinctive motifs can be printed onto steel surfaces.

- Imitation Effects PPGI: Beyond wood and stone textures, complex patterns like woven fabrics and camouflage can also be achieved.

PPGI Steel Coil – Value-Added Processing

Wanzhi Group not only offers PPGI steel coils in various styles—including solid colors, textures, and prints—but also provides a comprehensive suite of value-added processing services. These include slitting, leveling, bending, and composite processing, helping you transform PPGI steel into a state closer to the finished product while saving your project time and costs.

- Slitting: Precisely slit wide PPGI coils into multiple narrow strips at your specified widths, preparing them for subsequent roll forming or other production processes.

- Flat Rolling: Uncoils PPGI coils and shears them into flat sheets of fixed lengths, providing custom-sized panels for direct use or transportation.

- Bending: Uses bending machines to form flat sheets or rolled panels into specific angles like C-shapes or U-shapes.

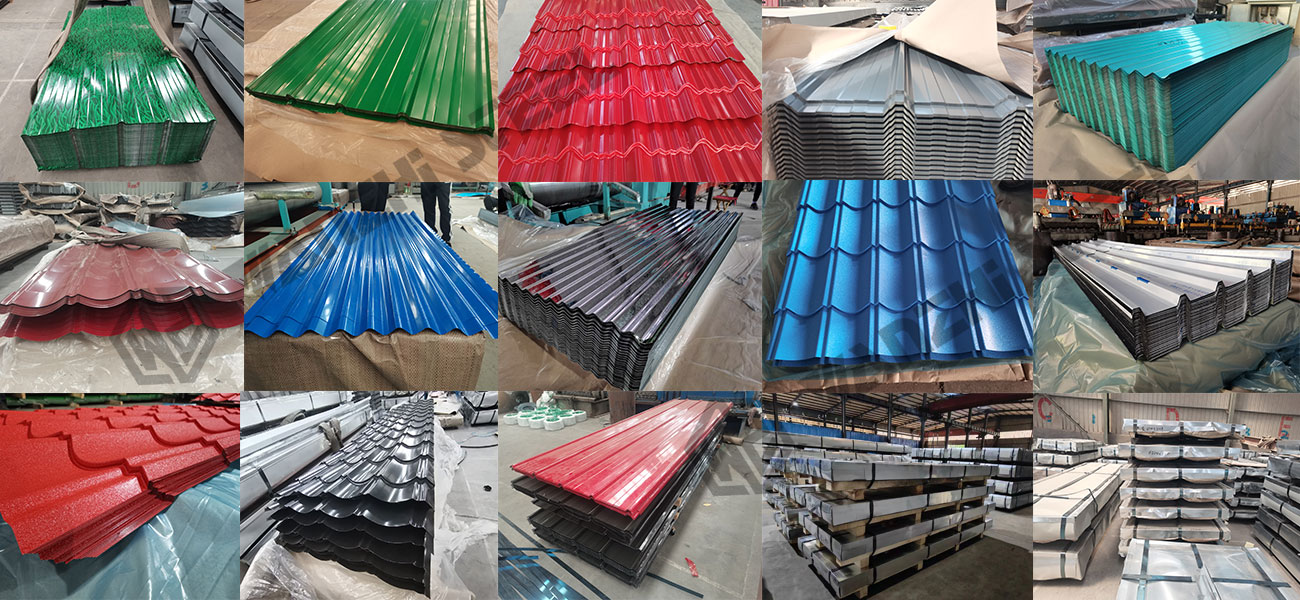

- Forming: Cold-forming PPGI sheet into panels with embossed surface structures, including corrugated, trapezoidal, ribbed, and other profiles.

- Composite Processing: Laminating color-coated sheets with core materials like polyurethane or rock wool to create PPGI sandwich panels, or bonding them with wood, gypsum board, or other substrates to form specialized composite materials.

PPGI Steel Coil – Manufacturer

As a professional PPGI steel coil manufacturer in China, Wanzhi Group possess independent production lines, laboratories, sample rooms, industry certifications, and product quality certificates. We also support quality inspections by third-party institutions such as SGS, BV, and TÜV.

Wanzhi Factory

Our prepainted steel factory is located in Boxing County, Binzhou City, Shandong Province, China. The facility houses galvanizing lines, galvanized-aluminum-zinc and zinc-aluminum-magnesium production lines, color coating lines, whiteboard production lines, and corrugated sheet processing lines. With an annual capacity of 600,000 tons, we maintain stock inventory of PPGI in raw materials, standard colors, and specifications. Delivery times start as fast as 5 business days, with a maximum lead time of 45 working days for customized products.

Packaging

Our packaging strictly adheres to export standards and meets customer requirements for transportation and storage. We offer various packaging options including vertical bags, horizontal bags, and wooden pallets, with weights customized to specific needs.

Customer Feedback

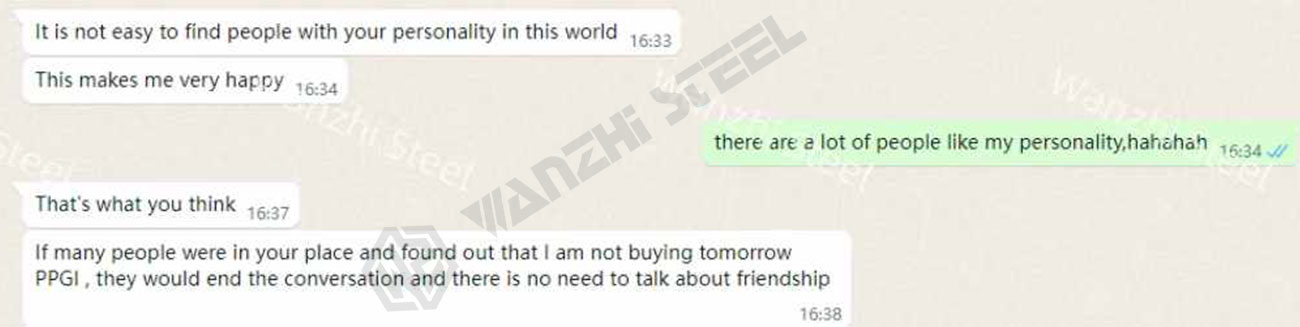

To date, our factory has hosted visitors from over 40 countries and regions worldwide. Our products are exported to more than 100 countries and regions, receiving feedback from diverse clients including manufacturers and traders.

Color Aluminum Cameroon Customer Feedback

Tin Free Plate Bolivia Customer Feedback

Textured PPGI Coil Georgia Customer Feedback

White PPGL Coil Chilean Customer Feedback

PPGI Coil for Whiteboard – Used Feedback

Client Feedback from Libya

Project Cases

We supply PPGI appliance panels to home appliance manufacturers, PPGI coils and sheets to roofing panel processors, PPGI coils and galvanized wire accessories to greenhouse projects, PPGI corrugated sheets and accessories to commercial hospitals, PPGI raw materials to whiteboard manufacturers, and more.

110 tons of Galvanized Steel Strip Shipped to Kazakhstan

300 tons of GI, GL, PPGL Coils Shipped to Sri Lanka

250 tons of GI Sheet &PPGI Coil Shipped to Lebanon

100 tons of Galvanized Wire to Chile

Whether you seek PPGI steel coil as raw material or require finished PPGI products, contact us for tailored solutions suited to your project.