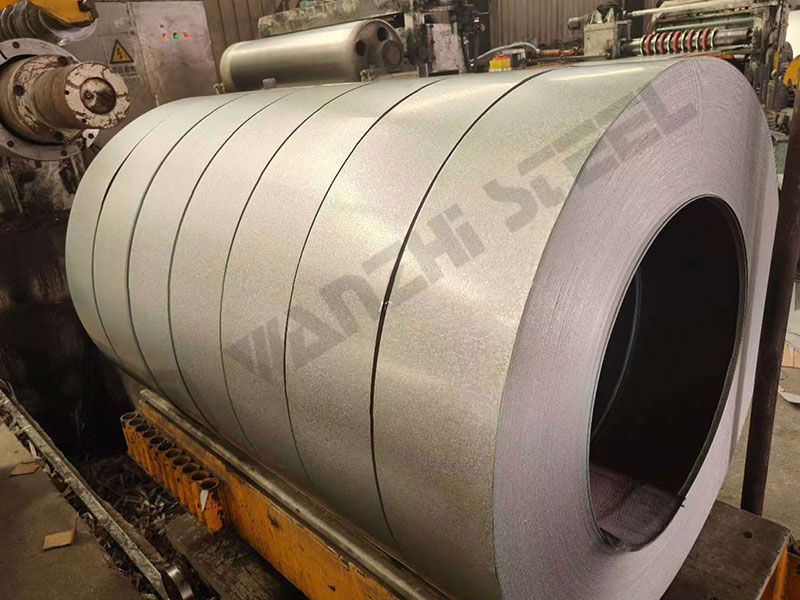

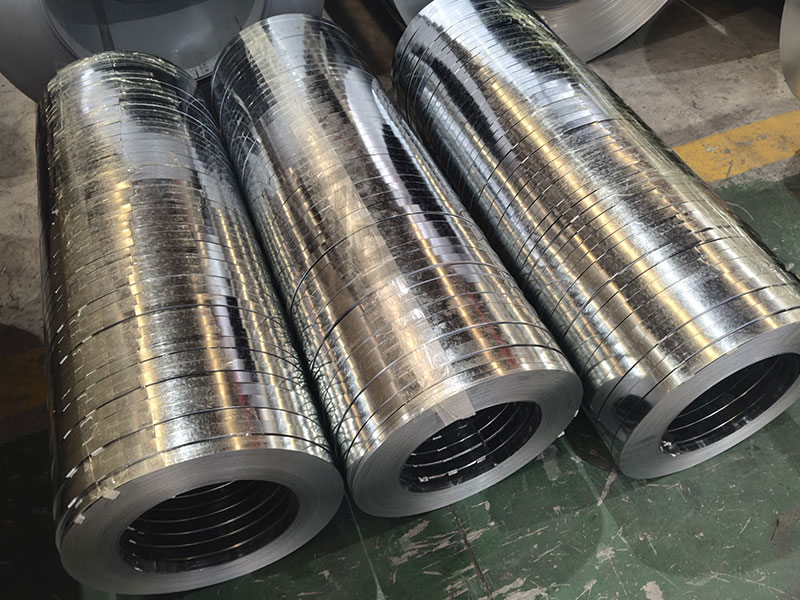

Spangle Galvanized Steel Strip, precision slit from hot-dip galvanized steel coils, features a spangle surface pattern naturally formed during the hot-dip galvanizing process. This pattern includes large spangles, small spangles, and regular spangles.

Spangle Galvanized Steel Strip for Sale

Wanzhi Group offers a diverse range of steel strip materials, including spangle galvanized steel strip, aluminum-zinc coated steel strip, stainless steel strip, and color-coated steel strip. We provide OEM ODM services tailored to specific application requirements.

Specifications

| Item | Details |

| Base Plate | DX51D, DX52D, DX53D, DX54D, Q195 – Q345/SGCC, G30, G60, G90SGCC, SGCD1, SGCD2, SGCD3, SGC340, SGC400, SGC440 |

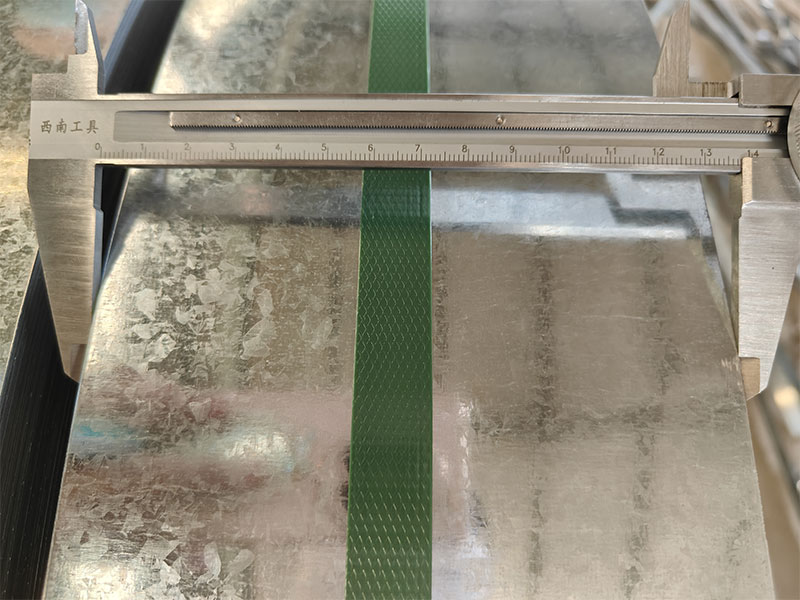

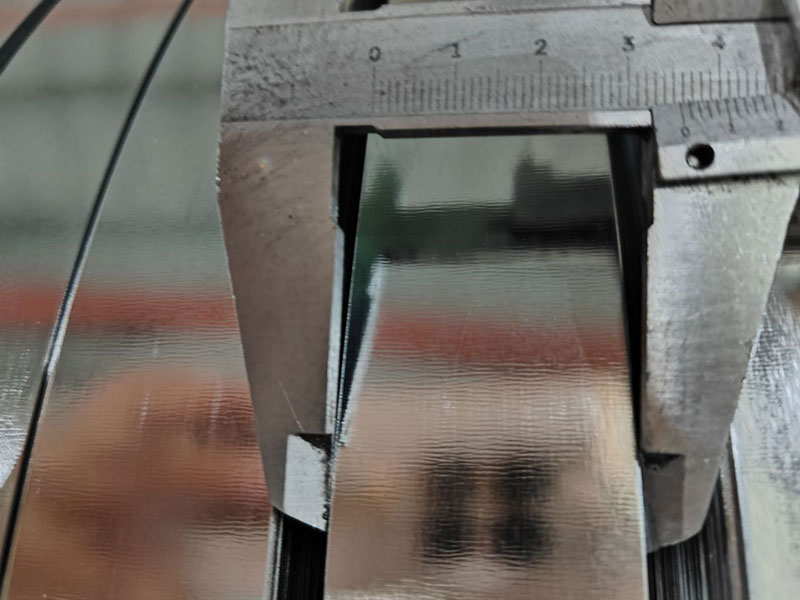

| Thickness | 0.15mm – 3.0mm |

| Width | 4mm – 1250mm |

| Zinc Coating | 30g/m² – 275g/m² (Z30 – Z275) |

| Inner Diameter of Steel Coil | Customizable |

| Surface Treatment | Passivation / Oil Coating / Paint Sealing & Fingerprint Resistance / Phosphating |

| Surface Spangle | Normal / Slight / Spotted |

| Unit Weight | Customizable |

| Packaging | Plastic Film + Moisture-Proof Paper + Galvanized Iron Sheet |

Surface

Currently, we offer three primary types of hot-dip galvanized steel strip with zinc spangle finishes:

- Minimal Spangle: Features a uniform, fine surface texture where zinc spangles are barely visible to the naked eye. This finish is achieved through specialized control of the zinc bath composition and cooling processes that inhibit excessive zinc crystal growth.

- Regular Spangle: Features clearly visible, medium-sized bright silver zinc spangle patterns. This surface is formed through standard hot-dip galvanizing processes and natural cooling crystallization.

- Large Spangle: Characterized by large, bright zinc crystals. Achieved by adjusting zinc bath composition and slowing cooling rates to promote uninhibited crystal growth, resulting in substantial, sparkling crystals.

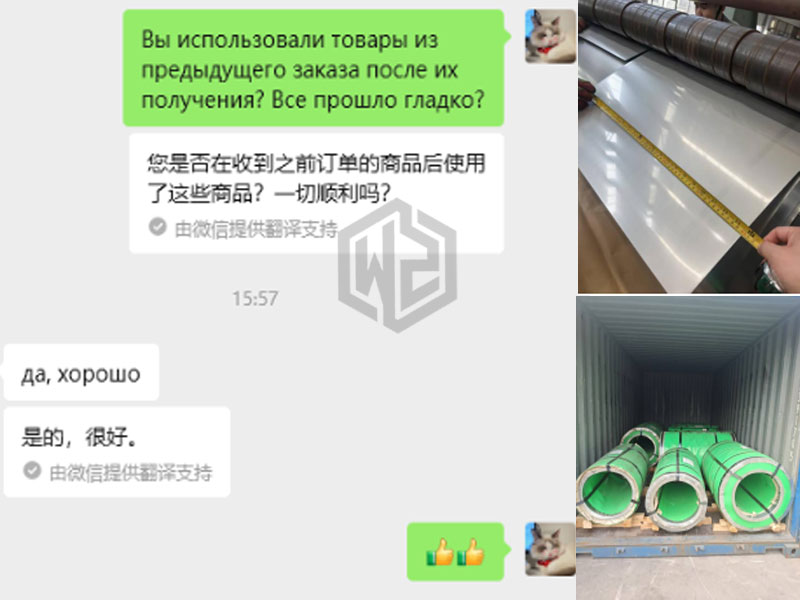

Case

Wanzhi Group has supplied galvanized steel coil, galvanized steel sheet, galvanized strip steel, and other raw materials to customers in over 100 countries and regions worldwide, along with value-added services including bending, leveling, slitting, and painting.

Advantages and Applications

Our spangle galvanized steel strip has been successfully used in a variety of applications, including building structures, steel structures, automotive manufacturing, household appliances, containers, ventilation ducts, and household hardware, due to its excellent corrosion resistance, good formability, superior surface quality, and relatively low cost.

Advantages of Spangle Galvanized Steel Strip

- Corrosion Resistance: The thick zinc layer of hot-dip galvanized steel effectively prevents rust on the steel substrate and prolongs its service life.

- Decorative Effects: The spangle pattern creates a beautiful visual effect, adding a unique aesthetic to the product.

- Processability: Spangle galvanized steel is suitable for complex forming processes such as stamping and bending.

- Cost-Effectiveness: Hot-dip galvanized steel strip is less expensive than other metal strip surfaces.

- Diversity: From small to large spangles, we offer a wide range of applications.

Applications of Spangle Galvanized Steel Strip

- Architecture and Structure: Roof grilles, wall panels, exterior decorative panels, roller shutters, ventilation ducts, steel structures, and C/Z sections.

- Automotive: Interior structural components, weatherstrip frames, and seat components. Light Industry: Appliance back panels and housings, sinks, exhaust hoods, and the outer coverings of large storage tanks.

- General Hardware: Granaries, silos, shutters, cable trays, various stamping parts, material storage and transportation, and packaging equipment.

Custom Spangle Galvanized Steel Strip

Wanzhi Group is a Chinese supplier of coated metal materials. Our factory features processing equipment for cold-rolled precision slitting, galvanized precision slitting, electrical steel precision slitting, and painted metal precision slitting. We also have a comprehensive supply chain management system, providing the most cost-effective spangle galvanized steel for applications in construction, home appliances, and other fields.

Factory

Our factory, Shandong Wanzhi Steel Co., Ltd., is located in Boxing County, Binzhou City, Shandong Province, China. We utilize advanced production lines and a strict quality management system, certified to ISO9001. Equipped with a continuous hot-dip galvanizing line, precision rolling mills, and automated control systems, we ensure that every roll of steel strip meets international standards (such as ASTM, JIS, and GB) as well as our own stringent internal quality requirements.

OEM/ODM Services

Custom Sizes: We can customize specific widths, thicknesses, and lengths according to your drawings.

Spangle Control: We can precisely control the size and uniformity of the spangles to meet your application requirements. Zinc Layer Weight: We offer products with varying zinc layer thicknesses to suit different corrosive environments.

Packaging: We offer a variety of packaging options, including vertical and horizontal packages, to ensure the product remains intact during transportation and storage.

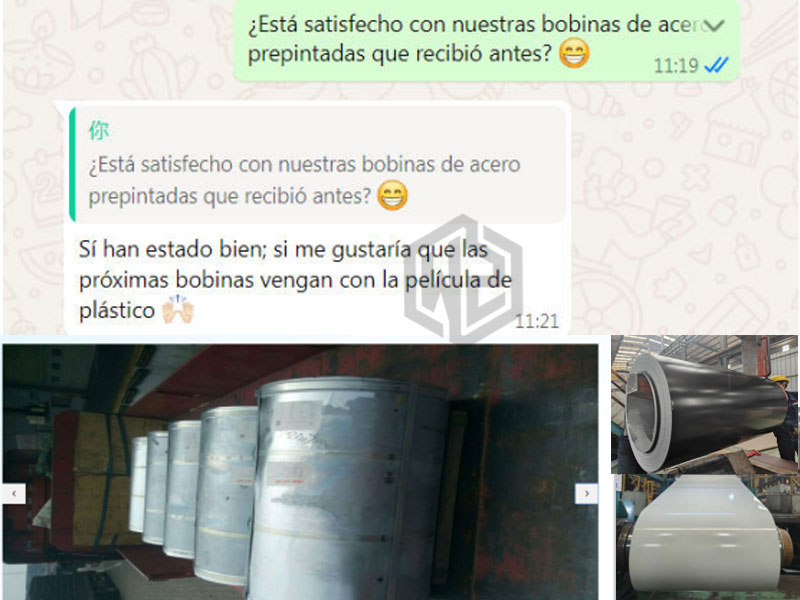

Feedback

We have established long-term partnerships with numerous businesses, factories, and engineering projects, and have earned widespread acclaim. We look forward to becoming your trusted partner and providing the highest-quality Spangle Galvanized Steel Strip for your projects.

Galvanized Steel Strip with zinc Spangles vs. Zero Spangel

| Characteristic | Spangled Galvanized Steel Strip | Zero-Spangled Galvanized Steel Strip |

| Process | Hot-dip galvanizing | Electro-galvanizing |

| Surface | Uneven, prone to dark spots after coating | Smooth surface, with good coating adhesion |

| Aesthetics | The spangled pattern has decorative appeal (in some scenarios) | Silvery-bright luster, suitable for high-end scenarios |

| Cost | Lower | Higher |

| Application | Building decoration, low-end manufacturing | High-end buildings, automobiles, household appliances |