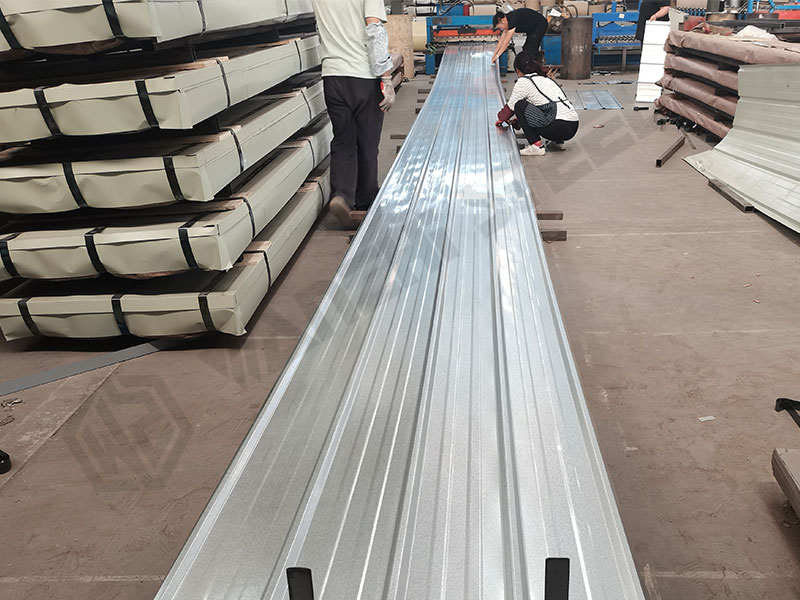

Ribbed Galvanized Steel Sheet is a galvanized sheet based functional steel with cold pressed ribs to increase the structural stability of the steel sheet. Wanzhi Group offers a wide range of corrugated shapes such as V-corrugated, U-corrugated, and curved corrugated, which provide one-stop service for applications such as walls, roofs, and façades of buildings.

Ribbed Galvanized Steel Sheet Properties

Ribbed galvanized sheet metal is a structural steel sheet with a ribbed design that provides greater resistance to bending and higher structural stability, and can form an I-beam effect when subjected to stresses to effectively disperse load stresses and thus inhibit local deformation.

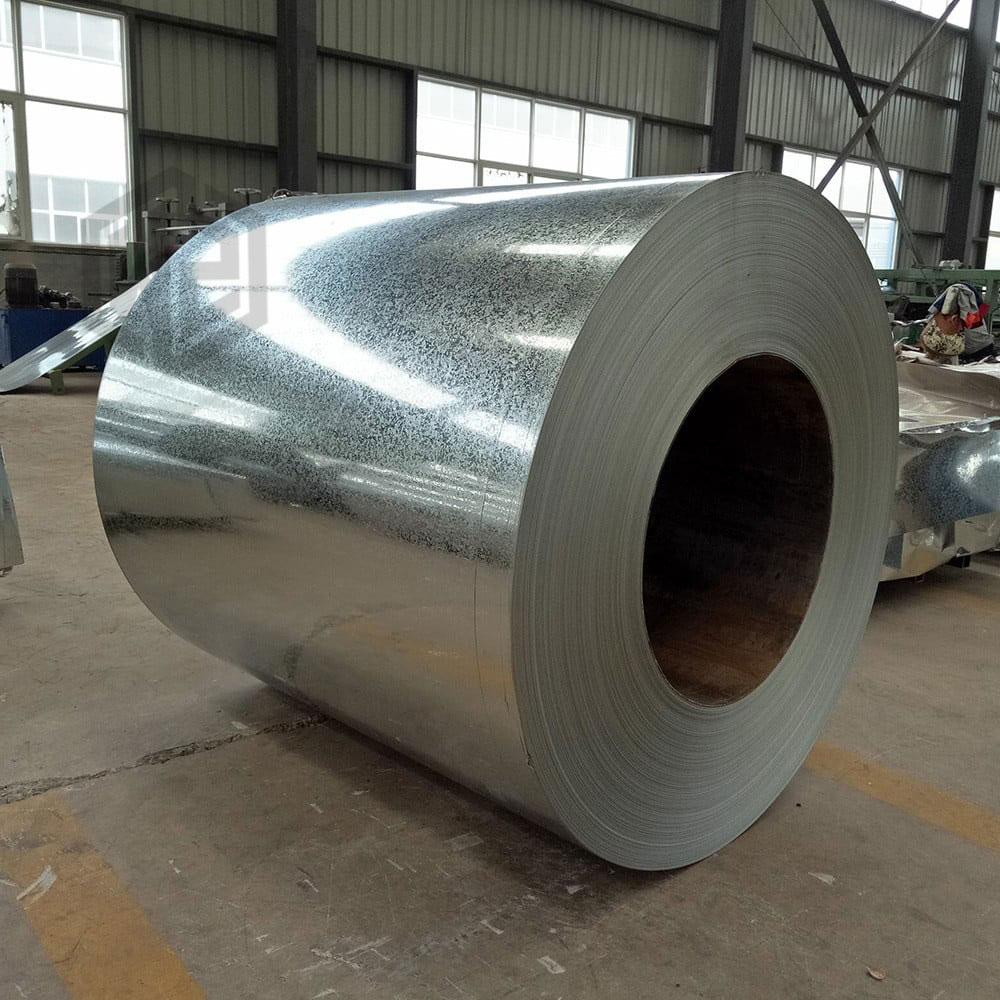

- Substrate: Hot-dip galvanized steel sheet / hot-dip galvanized steel coil (regular spangle galvanized, smooth galvanized, zero galvanized, etc.)

- Process: hot dip galvanized + roll forming cold bending

- Characteristics: corrosion resistance, high strength, increased flexural rigidity, drainage, anti-slip

Mechanical Properties (Base material: DX51D+Z, t=0.7mm)

| Performance Indicator | Rib Height 25mm Ribbed Plate | Rib Height 30mm Ribbed Plate |

|---|---|---|

| Section Moment of Inertia (Ix) | 1.42 cm⁴/m | 0.68 cm⁴/mm |

| Bending Stiffness (EI) | 298.2 kN·mm²/mm | 142.8 kN·mm²/mm |

| Allowable Span (L) | 3.8 m (Load 1 kPa) | 4.8 m |

| Local Compressive Strength | >15 MPa | 24.5 MPa |

| Fatigue Life | >10⁶ cycles | >2×10⁶ cycles |

Physical Properties

| Performance Indicator | Typical Value |

|---|---|

| Thermal Conductivity (λ) | 45~50 W/(m·K) |

| Thermal Resistance (R) | 0.02~0.03 (m²·K)/W |

| Solar Reflectivity | 0.70~0.85 (Galvanized Surface) |

| Coefficient of Thermal Expansion (α) | 12×10⁻⁶ /℃ (Axial) |

| 15×10⁻⁶ /℃ (Transverse) | |

| Sound Transmission Class (STC) | 22~26 dB (500Hz) |

| Surface Emissivity (ε) | 0.25~0.35 |

| Density (ρ) | 7850 kg/m³ |

Note: When choosing ribbed galvanized steel sheet as a material, two other issues that arise in practical applications need to be considered: the top of the ribbed zinc layer wears 20% more than the flat surface and the ribbed valleys are prone to waterlogging.

Core Applications and Scenarios

Ribbed galvanized steel shee is a cost-effective mechanical material for industrial buildings and can also be combined with other acoustic/thermal/insulation materials to form sandwich panels, which combine thermal insulation, fire protection and load-bearing.

Material Selection

The golden rule of selection: span determines the rib height, load determines the plate thickness, corrosion determines the zinc layer, and deformation determines the base material.

- The larger the span, the greater the bending stress and load the steel plate needs to withstand, and the rib height needs to be increased.

- The heavier the weight of the plate, the greater the thickness of the plate.

- In more corrosive environments, a thicker layer of zinc is required to extend the life of the plate.

- Steel plates change shape when subjected to external forces. Cold rolled steel, hot-dip galvanized steel, and aluminum-zinc alloy steel are selected as the base material according to the external forces that the steel plate needs to withstand.

Applications

Industrial Building Roofs/Walls

- Requirements: Ribbed pattern to divert rainwater and prevent water accumulation (slope ≥5°), high stiffness to resist wind pressure (especially in typhoon areas).

- Recommendation: Rib height 25~40mm, plate thickness 0.4~0.8mm (span 6~12m)

- Cases: factory buildings, logistics warehouses, hangar roofs, galvanized ribbed steel roof panel

Agricultural Greenhouse Structure

- Requirements: Drainage and drainage, compression resistance

- Recommendation: Rib height 25~40mm, plate thickness 0.4~0.8mm (span 6~12m) galvanized steel, Aluminum zinc plated plate.

- Cases: greenhouse growing greenhouses, agricultural nursery greenhouses, ecological greenhouses, etc. Roof and wall covering, ventilation system, sun-shading facilities

Construction

- Requirements: Thermal insulation, thermal insulation

- Recommendation: ribbed galvanized steel sandwich panel with rib height ≥25mm + PU insulation/highly reflective galvanized layer.

- Examples: Cold chain logistics centers, high-temperature workshops, cold storage partitions

Marine Engineering

- Requirements: Anti-slip, salt spray corrosion resistant,Comply with DNV/ISO 12215 marine material specification

- Recommendation: Z275

- Case: Ship decks and bulkheads

Transportation

- Requirements: High flexural strength, non-slip

- Recommendation: Stamped ribbed steel sheet/punched/perforated ribbed steel sheet

- Example: Truck/trailer flooring

Sound Barrier Substrate

- Requirement: Reduce noise reflection

- Recommended: Ribbed plate (0.8mm) + 50mm rock wool + perforated aluminum plate

- Examples: Highway sound barriers, machinery platforms

Ribbed Galvanized Steel Sheet for sale

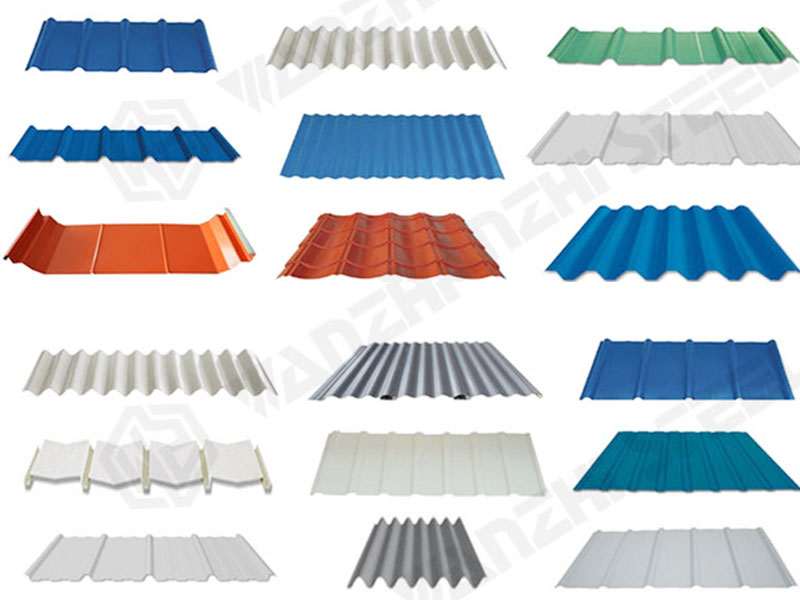

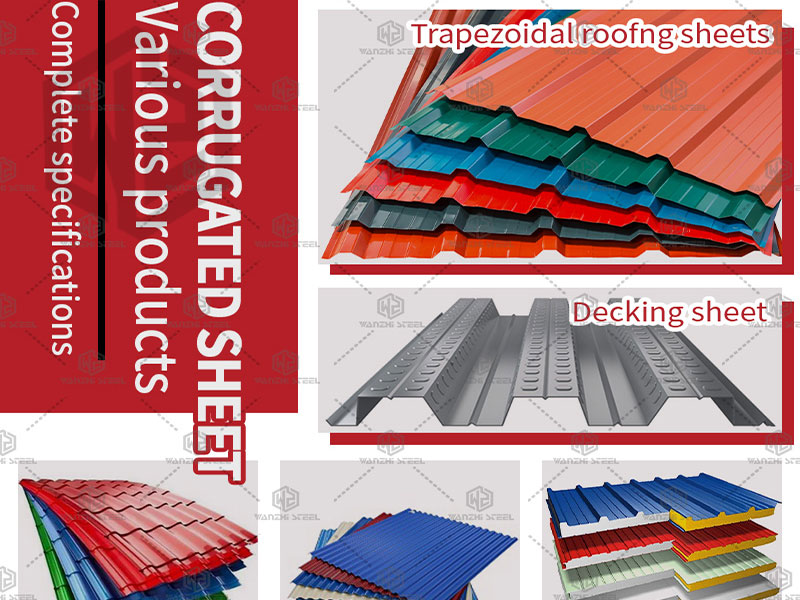

Wanzhi Group produces and sells corrugated sheet in many materials, including ribbed galvanized steel sheet, galvanized ribbed steel wall panel, galvanized galvanized steel roof panel, we have 2 galvanized production lines and sheet processing equipments in our factory, we provide OEM,ODM service.

Raw Material (galvanized) Specifications

| Material | SGCC,S350GD+Z,S550GD+Z,DX51D,DX52D,DX53D, etc |

|---|---|

| Thickness | 0.12mm-6mm |

| Width | The conventional width below 0.5mm is 1000mm, 1200mm, and above is 1000, 1250mm |

| coil weight | 8-10 tons /customized |

| Tolerance | "+/-0.02 mm |

| Substrate Type | Hot rolled coil, Cold rolled coil |

| Surface structure | Zero spangles, Small spangles, Regular spangles, Big spangles |

| Zinc layer thickness | 30g/㎡-275g/㎡ (Z275/G90) |

| Standard | AISI, ASTM, BS, GB, JIS |

| Implementation standards | GB/T2518 GB/T25052, EN10346, JIS G3302, ASTMA653 |

| Certificates | SGS, ISO 9001,CE |

Finished Products for Sale

Wanzhi steel factory provides further processing services such as bending, slitting, punching, punching, painting and forming. In addition to galvanized coils, we can also design and produce various materials and specifications according to your needs.

- Corrugated sheet

- Ribbed Plate

- Perforated sheet

- Stamped plate

- Sandwich plate

- Painted board

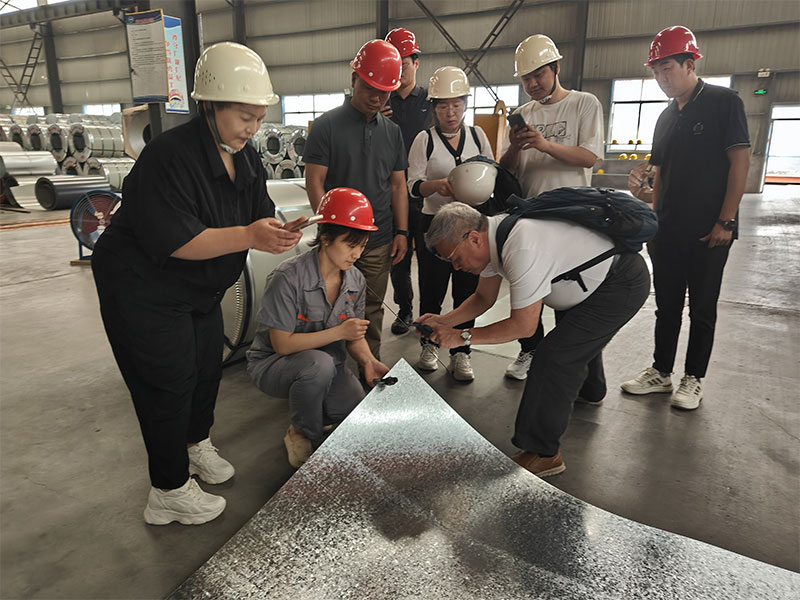

Factory

Our factory is located in Boxing County, Binzhou City, Shandong Province, China, with galvanizing, alloying and painting production lines, with an annual production capacity of more than 600,000 tons. In addition, we have a sample room where we can provide free samples of conventional galvanized metal materials. If you plan to visit our coated steel factory or need samples, please feel free to contact us!

Ribbed Steel Sheet VS Other Structural Sheets

| Panel Type | Cost | Strength-to-Weight Ratio | Corrosion Resistance | Applicable Span |

|---|---|---|---|---|

| Ribbed Galvanized Plate | Low | Extremely High | High | ≤12m |

| Corrugated Color Steel Plate | Medium | Medium | Extremely High | ≤9m |

| Aluminum-Magnesium-Manganese Plate | High | High | High | ≤15m |

| FRP Skylight Plate | Medium | Average | Medium | ≤6m |

Ribbed Galvanized Steel Sheet Substrate Selection Advice

If you are selecting a metal material for your project, you can determine the required steel properties based on the application scenario. For example, steel structural applications require a substrate with high elongation, while highly corrosive environments require a steel substrate with high salt spray resistance.

- DX54D+Z galvanized steel sheet with elongation A80≥18% is recommended for highly deformed components.

- S350GD+Z galvanized steel sheet with a recommended yield strength of ≥350MPa for heavy-duty structures.

- For applications in highly corrosive environments, we recommend AZ150 zinc-aluminum-plated steel sheet with a corrosion resistance of 2 times that of Z275.

- For low temperature applications only, we recommend HX420LAD+Z galvanized steel sheet with toughness number.

Ribbed Galvanized Steel Sheet – FAQ

Ribbed Galvanized Steel Sheet is a widely used construction material. What should I do if there are problems such as corrosion, rust, deformation, waterlogging, etc. during use?

If the ribbed steel sheet is exposed to humid, acidic or alkaline environment for a long period of time, the surface will be easily corroded and rusted. In order to minimize the rusting and prolong the service life, you can clean the surface of the steel sheet regularly, make good corrosion prevention and sealing at the joints, and make timely repairs to the damaged areas.

Ribbed plate is subject to strong external impact, temperature changes and other conditions back to deformation, cracking and other problems, these problems need to be considered in advance when selecting materials, in addition to the use of the process should be properly protected, to avoid frequent external impact and excessive bending.

The drainage problem of the ribbed plate can be solved by designing a reasonable drainage system and installing waterproof material at the joints of the steel plate.

The noise generated by the wind and rain when the metal plate is used as a wall or roof panel affects the comfort of the room. The spread of noise can be reduced by installing sound-absorbing cotton, soundproof boards, and support frames.

High quality building materials ribbed galvanized steel sheet suppliers-Wanzhi Group, we improve one-stop service, from design and production to personalized customization, come to buy your own metal materials!