AluZinc (also known as Galvalume, Zincalume, or 55% Al-Zn alloy coated steel) represents a revolutionary leap in corrosion protection technology for steel substrates. Combining the barrier resistance of aluminum with the sacrificial protection of zinc, this material has become the gold standard for long-life, low-maintenance metal solutions across industries. Here’s a comprehensive analysis of its science, standards, and applications.

Definition & Core Composition

AluZinc material is a continuous hot-dip coated steel product ,high-performance metal plating materials made of aluminum (Al), zinc (Zn) and a small amount of silicon (Si) compounded by the hot-dip plating process.

- 55% Aluminum (forms a dense oxide barrier against corrosion/UV)

- 43.4% Zinc (provides cathodic “sacrificial” protection)

- 1.6% Silicon (ensures alloy adhesion to steel, prevents brittleness)

Common Product Forms

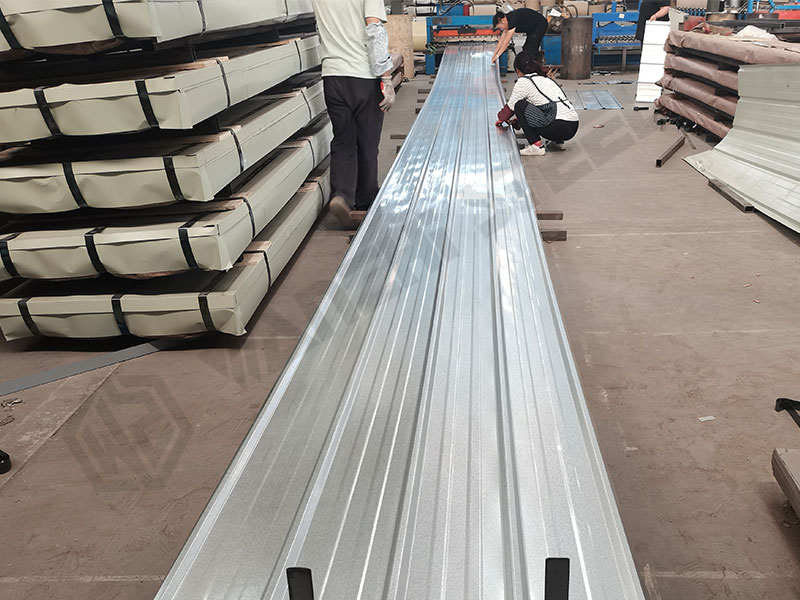

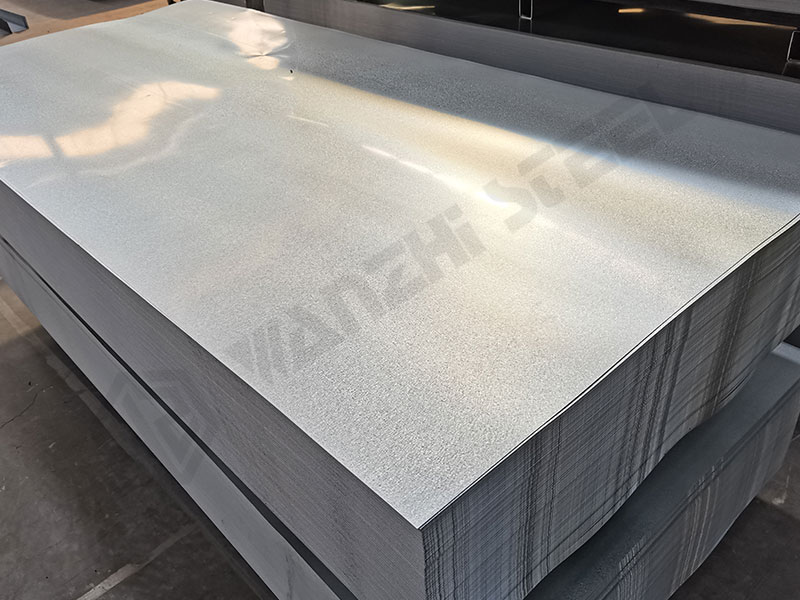

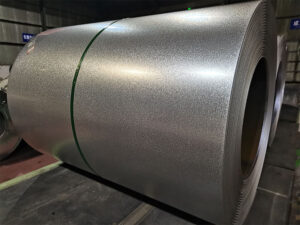

AluZinc materials are usually supplied in the form of sheets and coils, however, AluZinc steel has good ductility and toughness and can be further processed by bending, stamping, forming, profiling, painting, striping, etc.

| Form | Thickness Range | Width Range | Surface Finish |

| Coils | 0.15–6.0 mm | 600–1,250 mm | Skin-passed, dull/regular |

| Sheets/Cut lengths | 0.15–6 mm | Custom sizes | Matte, stucco, embossed |

| Pre-painted coils | 0.12–1.5 mm | 600–1,250 mm | PVDF/SMP/PE/HDP coatings |

| Roofing | 0.12-1.0 | Custom sizes | Corrugated, rippled, curved, folded corners, etc. |

| Strips | 0.12–6.0 mm | Custom sizes | Skin-passed, dull/regular |

| Steel profile | Custom sizes | Custom sizes | C-beam, Z-beam, H-beam and so on. |

Key International Standards

Wanzhi steel factory has passed ISO 9001 quality management system certification and ISO 14001 environmental management system certification. Our akuzinc materials comply with EN, ASTM, JIS, GB and other national standards. Common plating weights: AZ100 (100g/m²), AZ150 (150g/m²), AZ180 (180g/m²).

| Standard | Designation | Key Parameters |

| EN 10346 | DX51D+AZ, DX54D+AZ | Coating mass (e.g., AZ150=150g/m²) |

| ASTM A792/A792M | Grade 40, 50, 60 | Tensile strength (ksi), coating class |

| JIS G3321 | SGCC AZ | Japanese Industrial Standard |

| GB/T 14978 | AZ | Chinese National Standard |

Base Steel Substrates

Performance depends on underlying steel grade:

Commercial Grades (DX51D/DX52D):

- For roofing/walling, bending/roll-forming.

- Yield strength: 140–280 MPa.

Structural Grades (S320GD/S550GD):

- High-strength applications (solar racks, frames).

- Yield strength: 320–550 MPa.

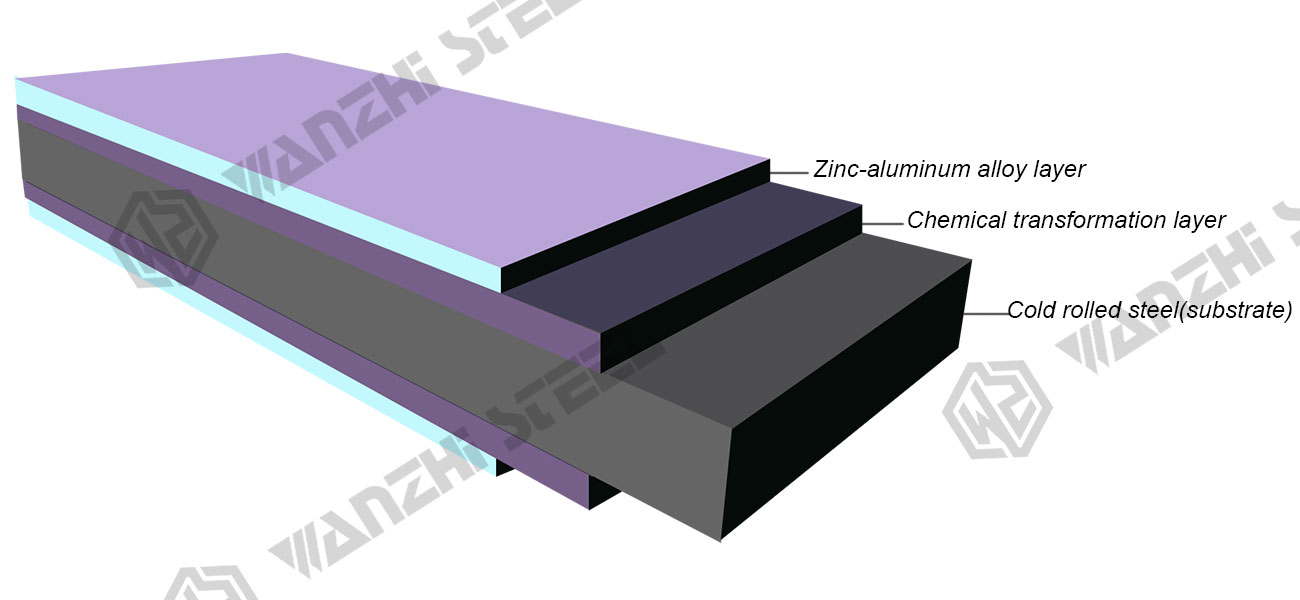

Coating Structure & Protection Mechanism

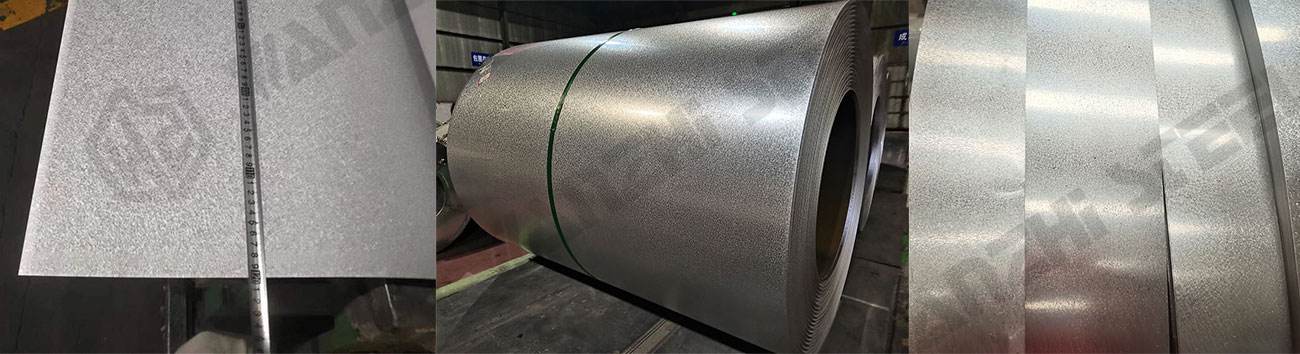

Aluzinc steel materials consist of cold rolled steel coils and aluminum-zinc alloy coatings.

Coating Structure

- Aluminum-Rich Phase:Forms Al₂O₃ passive layer

- Zn-Al Eutectic Phase:”Sacrificial anode”

- Fe-Al-Zn Alloy Layer:Si prevents Fe-Zn brittleness

Protection Mechanisms

- Physical barrier formed by the oxide film of aluminum

- Electrochemical protection by zinc.

Superior Performance Advantages

- Corrosion Resistance: 3–6× GI in marine/industrial environments (ISO 9227).

- Cut-Edge Protection: “Self-healing” zinc-rich phase seals exposed edges.

- Heat Reflectivity: 75–80% solar reflectance (reduces building cooling loads by 20%).

- Temperature Tolerance: Stable up to 315°C (vs. GI’s 200°C limit).

- Paint Adhesion: T-Bend: 0T-1T (EN 13523-7), ideal for PVDF coatings.

Dominant Application Sectors

| Industry | Use Cases |

| Construction | Roofing, siding, gutters, rainwater systems |

| Solar Energy | Mounting structures, tracker components |

| Automotive | Exhaust shields, trim parts |

| Appliances | HVAC ducts, oven cavities, backsplashes |

| Agriculture | Grain silos, livestock buildings |

Customization Options

Wanzhi Group has a professional galvanized /Aluminum Zinc Plating / Galvanized Aluminum Magnesium Plating production line in our factory, which includes advanced cleaning equipment, imported air knives, zinc layer thickness monitoring equipment, finishing machine + straightening machine, surface inspection system, which ensures that the coated steel produced is uniformly plated and the surface is flat and smooth according to the requirements. In addition to production, we can provide OEM,ODM service for construction, industry, energy and other fields.

| Feature | Description |

| Coating Mass | AZ20 to AZ350 (g/m²) |

| Surface Texture | Regular spangle, zero spangle, embossed (leather/linen) |

| Post-Treatments | Chromate-free passivation, oiling, laminating |

| Pre-Painting | RAL color matching, anti-graffiti coatings |

| Further Processing | Opening, striping, bending, forming, etc. |

Aluzinc Steel Purchasing Advice

When purchasing Aluzinc material, you can ask the Aluzinc factory to provide the factory test certificate (MTC), IS14001, ISO9001 and other certificates, to ensure that the supplier’s authenticity and ability to deliver meet the requirements. In the material selection process, you can also reduce costs by choosing the right coating, steel substrate, and surface treatment.

Cost priority

- Select coating according to the application environment: AZ120 aluzinc steel for general environment, AZ150-AZ180 for high corrosive environment

- Select specification according to the use: Minimum thickness is calculated for design load, and standard width (600mm-1250mm) is preferred to reduce waste.

Demand Priority

- Priority for load-bearing demand is given to aluzinc steel made of high-strength carbon steel plate as the substrate.

- Decorative and general purpose can choose mild steel cold rolled aluminum zinc plated steel.

Wanzhi – Hot Products

Aluminum-zinc alloys combine the barrier properties of aluminum with the sacrificial protective properties of zinc to dramatically reduce life-cycle costs while enabling sustainable design is a corrosion-resistant metallic material with an exceptionally high investment exchange rate.