Hot Dipped Galvanized Steel is an indispensable raw material for bridges, power grids, building steel structures/roofs/enclosures, automotive components and agricultural equipment due to its excellent corrosion resistance and cost-effectiveness. Today, join Wanzhi Group to learn more about hot dipped galvanized steel from its manufacturing process, core specifications, performance advantages, and multiple applications!

Definition of Hot Dipped Galvanized Steel, HDG

Hot Dipped Galvanized Steel (HDG) is a carbon steel substrate (cold rolled steel, hot rolled steel) that has been subjected to a rigorous surface cleaning process and immersed in a bath of molten, pure zinc at approximately 450°C. Metallurgical reactions result in the formation of a series of iron-zinc alloys on the surface of the steel substrate with an outermost pure zinc layer to achieve a strong adhesion, corrosion resistance, and a service life of more than 20 to 50 years. In addition, hot-dip galvanized steel has a high zinc deposition on the surface, usually with a pattern of zinc crystals of various sizes, the size of which can be technically adjusted.

- Sacrificial anode protection: When the coating of galvanized steel is broken or cut edges are exposed, the zinc will preferentially corrode and dissolve, protecting the steel from erosion.

- Physical barrier protection: The complete, dense galvanized coating isolates the steel from corrosive media (oxygen, water vapor, salt, etc.).

Hot Dipped Galvanized Material and Specification

Wanzhi Group produces and sells hot-dip galvanized steel in accordance with international standards such as ASTM A36, A653, EN 10025-2, JIS G3101, G3131, G3302, etc.

| Material | SGCC,S350GD+Z,S550GD+Z,DX51D,DX52D,DX53D, etc |

|---|---|

| Thickness | 0.12mm-6mm |

| Width | The conventional width below 0.5mm is 1000mm, 1200mm, and above is 1000, 1250mm |

| coil weight | 8-10 tons /customized |

| Tolerance | "+/-0.02 mm |

| Substrate Type | Hot rolled coil, Cold rolled coil |

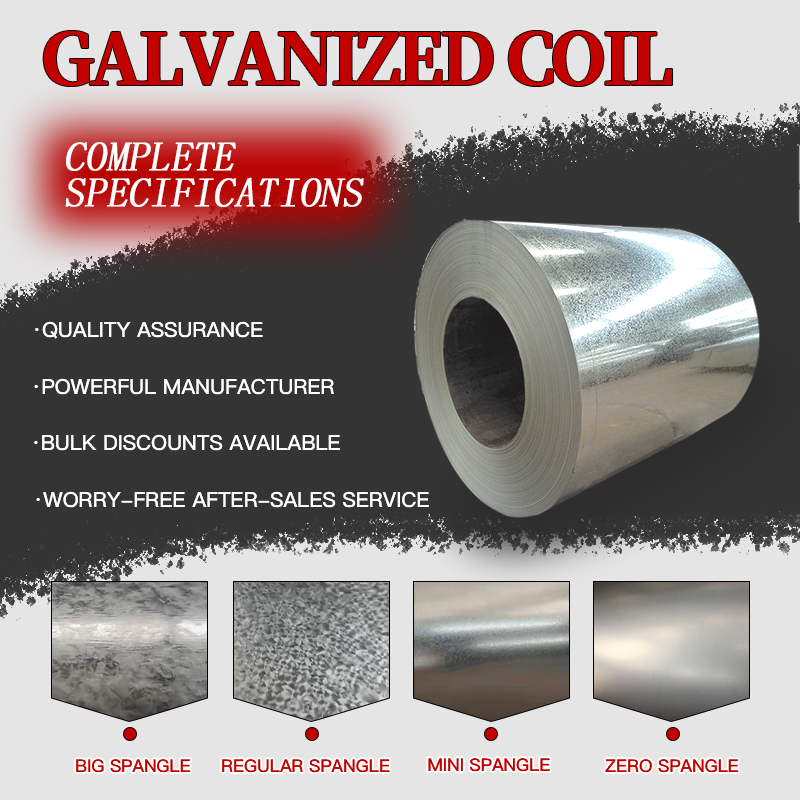

| Surface structure | Zero spangles, Small spangles, Regular spangles, Big spangles |

| Zinc layer thickness | 30g/㎡-275g/㎡ (Z275/G90) |

| Standard | AISI, ASTM, BS, GB, JIS |

| Implementation standards | GB/T2518 GB/T25052, EN10346, JIS G3302, ASTMA653 |

| Certificates | SGS, ISO 9001,CE |

Substrate Material

- Material: DX51D,SGCC,SPHC,S235JR, S355JR,SS400

- Chemical Composition: (C, Mn, P, S, Si, etc.)

- Strength: 250 MPa~550 MPa

Product Form

- Steel Sheet/Coil: 0.15-6mm hot-dip galvanized steel coil is the most common form of hot degree modification, which is divided into galvanized thin sheet, medium thick sheet and thick sheet. Standard width 600-1250mm, or customized.

- Pipe: Structural pipes, water pipes, threading pipes, profiles/wires/fasteners: Angles, channels, I-beams, reinforcing bars, bolts, nuts etc.

- Pressure plate: corrugated plate, perforated plate, punched half, stamped plate, sandwich plate, ribbed plate, etc.

- Grating/fence/hardware: all kinds of prefabricated components.

Coating Weight/Thickness

The zinc coating of galvanized steel is expressed as if it were the mass of zinc per unit area (e.g. grams per square meter g/m², or ounces per square foot oz/ft²). It can also be converted to an approximate thickness (micron μm, or mil mil).

Note: Plating weight/thickness requirements usually refer to the sum of both sides.

- Z100: 100 g/m², ~10 μm, for indoor or dry conditions.

- Z150: 150 g/m², ~15 μm, suitable for general industrial buildings or domestic use.

- Z180: 180g/m², ~18 μm, suitable for medium corrosive environments.

- Z275: 275 g/m², ~27 μm, suitable for medium – heavy corrosive environments.

- G60: Thinnest, 0.60 oz/ft², ~20 μm for light corrosive environments or indoors.

- G90: Commonly used standard, 0.90 oz/ft², ~30 μm. most versatile.

- G115: Thicker coating, 1.15 oz/ft², ~40 μm. For medium to heavy corrosive environments.

- G140 / G165 / G210: Extra thick 50-90 μm coating for harsh environments (e.g. marine, industrial, chemical plants).

Surface Appearance

- Spangle: A grain pattern formed when molten zinc solidifies.

- Regular Spangle: A distinctive shiny snowflake-like crystallization visible to the naked eye.

- Minimized Spangle: A small, uniform, invisible zinc spangle that provides a more uniform and smooth surface for subsequent painting.

- Spangle-Free: Very smooth and even surface, almost invisible crystalline patterns, commonly found on electro-galvanized steel surfaces or on hot-dip galvanized surfaces that have undergone additional treatment (e.g. air knife control, specific alloys).

Composition and Structure of Hot-dip Galvanized Coating

Galvanized steel is a metallurgical bond between the coating and the steel substrate. The structure consists of a steel substrate, an iron-zinc alloy layer, and a zinc layer.

The base of the hot-dip galvanized coating is hot-rolled or cold-rolled steel. The alloy layer is divided into Γ-phase (Fe₃Zn₁₀) / δ₁-phase (FeZn₇) and ζ-phase (FeZn₁₃) to provide the base adhesion and barrier, and the pure zinc layer sits on top of the alloy layer to provide the main sacrificial protection.

Core Performance Benefits

Core Application Areas

Hot-dip galvanizing is used in a wide range of applications, from buildings and structures, transportation, utilities and energy, agriculture, industry, to everyday life, covering all aspects of our lives.

- Steel structure buildings (beams, columns, purlins, supports)

- Roofs, walls (especially for industrial buildings)

- Stairs, platforms, aisle gratings

- Doors, window frames, louvers

- Scaffolding, templates

- Automobile chassis components, internal structural parts, fuel tanks, exhaust pipe brackets

- Trucks, trailer frames, compartments

- Highway guardrails, noise barriers, traffic signage brackets

- Railway railroad track facilities (fasteners, gaskets), compartment parts

- Transmission pylons, substation frames

- Street light poles, signal light poles

- Electric wire and cable bridges, stringers

- Wind power tower internal structure, platforms

- Solar racks (especially for ground power stations)

- Grain bins, livestock shed structures

- Agricultural equipment (e.g., harvester frames)

- Irrigation piping, brackets

- Fences, grills

- Piping systems (water, gas)

- Equipment frames, guards

- Racks, storage cages

- Heating, ventilation and air-conditioning (HVAC) air ducts, brackets

- Chemical equipment peripheral structure, platforms

- Hardware ( Bolts, nuts, washers, hinges)

- Mailboxes, trash cans

- Patio furniture, barbecue grills

- Electrical enclosure interiors

Hot-Dip Galvanizing Process Explained

The hot-dip galvanizing process is a precisely controlled metallurgical process with major steps including substrate selection and treatment, hot-dip galvanizing processing, and post-treatment.

Finished Hot-dip Galvanized Steel: Standards and Inspection

| Standard | Description |

| ASTM | A123/A123M: Hot-dip galvanizing for rolled and pressed steel products (steel plates, sections, pipes, etc.).

A153/A153M: Hot-dip galvanizing for steel hardware (bolts, nuts, washers, etc.). A767/A767M: Hot-dip galvanizing for reinforcing steel used in concrete. A1063: Hot-dip galvanizing for structural steel pipes. |

| EN | EN ISO 1461: Hot-dip galvanized coatings on iron and steel products – Specifications and test methods (most general).

EN 10346: Continuous hot-dip galvanized steel sheets and coils – Delivery technical conditions (includes HDG plate coils). |

| JIS | JIS H 8641: Hot-dip galvanizing.

JIS G 3302: Hot-dip galvanized steel sheets and coils. |

| AS/NZS (Australia/New Zealand Standards) | AS/NZS 4680: Hot-dip galvanizing for iron and steel products. |

Hot Dipped Galvanizing (HDG) vs. Electro Galvanizing (EG/Z)

There are significant differences between hot-dip galvanizing and electro galvanizing in terms of structure, thickness, and performance.

| Characteristic | Hot-Dip Galvanizing (HDG) | Electro-Galvanizing (EG) |

| Process Principle | Metallurgical bonding | Physical/electrochemical deposition |

| Coating Structure | Zinc-iron alloy layer + Pure zinc layer (Eta) | Single layer of pure zinc |

| Coating Thickness | Thick | Thin |

| Corrosion Resistance Life | Extremely long | Moderate |

| Protection for Cuts/Scratches | Excellent | Limited |

| Coating Adhesion | Extremely strong | Good |

| Coating Hardness/ Wear Resistance | High | Lower |

| Appearance | Typically has spangle (can control size), shiny silver-gray | Smooth, even surface, grayish-white |

| Cost Factor | Relatively low | Relatively high |

| Typical Applications | Large structural components: construction steel structures, bridges, transmission towers, fences, pipelines, etc. | Small parts/thin plates: automotive panels, home appliance panels, hardware parts, wires, fasteners |

HDG EG Summary Selection Advice

- Wear-resistant, impact-resistant hot-dip galvanized steel is the best choice when the application requires extremely long service life (20 years or more) and low maintenance and involves reprocessing that involves trimming, drilling, welding, mounting, or for the production of large structural parts.

- Electro-galvanized steels are suitable for applications with low corrosion resistance, high surface finish and uniformity, or where precision machining is required, e.g. small, complex shapes or wires with very mild corrosion environments and short life expectancy, automotive exterior panels, precision components, etc.

Frequently Asked Questions (FAQ)

Q: How long does hot-dip galvanizing protect against corrosion?

A: 20-70 years, the corrosion resistance is affected by the thickness of the zinc layer and the corrosiveness of the environment, the thicker the zinc layer, the better the corrosion resistance.

Q: What is “white rust” on the surface of hot-dip galvanized coating? Is it serious?

A: “White rust” is mainly alkaline zinc carbonate (Zn₅(CO₃)₂(OH)₆) formed under humid environment. It is not a substrate corrosion per se, but a depletion of the plated zinc. Although it affects the aesthetics, it usually does not affect the corrosion resistance at the initial stage.

Q: Can hot-dip galvanized steel be welded?

A: Yes.

Q: Can hot-dip galvanized steel be painted directly?

A: Yes, it is possible and can significantly extend the life. However, a surface treatment is required before painting to enhance the adhesion of the coating and to prevent the coating from peeling off at a later stage.

A: The core difference is in the coating composition:

HDG: Pure zinc coating (>98% Zn).

Galvalume: 55% Al, 43.4% Zn, 1.6% Si. Significantly better than HDG in terms of corrosion resistance (especially in cuts) and heat resistance (~315°C), but more costly, more complex to weld, and slightly less formable in some respects. Mainly used for high-end construction panels and appliances.

The “better” depends on the need: HDG for the best price/performance ratio and heavy duty construction; Galvalume for long life (especially for architectural panels) and budge.

A: Possible reasons: storage stains, silicon reactive steel, localized over-alloying, uneven cooling.

A: Main test items:

Coating thickness/weight: Magnetic thickness gauge method.

Appearance: Visual inspection of uniformity, flow, leakage, burr, zinc gray and other defects.

Adhesion: Bending test.

Uniformity: Copper sulfate test.

White rust resistance: Salt spray test evaluation.

Hot Products – Wanzhi Group

Hot-dip galvanized steel has become one of the indispensable metal materials in modern industry, infrastructure and daily life due to its excellent sacrificial anodic protection capability, adaptability to large and complex structures, and excellent cost performance. For more information about Wanzhi Group galvanized steel, please feel free to contact us for prices, examples, solutions and customization process.